Steel shredder machines have transformed the landscape of metal recycling and waste management, ushering in an era where efficiency, expert innovation, and reliability converge to meet the demands of a modern, sustainable environment. With a combination of cutting-edge technology and robust engineering design, these machines offer the quintessential solution for processing scrap steel, opening avenues for enhanced material recovery and environmental preservation.

Experience reveals that integrating steel shredder machines into your recycling operations can dramatically streamline the process of waste reduction. Whether dismantling cars, demolishing industrial structures, or recycling consumer goods, these machines efficiently tear through sizable metal objects, breaking them down into smaller, more manageable pieces. This shredding not only reduces the volume of scrap material but also significantly enhances the purity and quality of the recovered metal. By focusing on the granularity of the output, operators can achieve precise control over downstream processes such as sorting, cleansing, and melting, ultimately maximizing the yield of reusable materials.

In terms of expertise, the design and operation of steel shredder machines encapsulate decades of engineering advancements in metallurgy and mechanical systems. These machines are equipped with powerful motors and high-torque shafts designed to handle the rigors of heavy-duty shredding tasks. Blades crafted from high-grade alloy steel ensure longevity and precision, capable of maintaining performance even after processing tons of metal. Furthermore,

modern shredders are integrated with intelligent systems that optimize performance. These systems can adapt shredding speeds and torque to the material being processed in real-time, minimizing downtime and wear while boosting operational efficiency.

Authoritativeness in the realm of steel shredding is often reflected in the industry standards and certifications these machines adhere to. Reputable manufacturers stay abreast with international safety, quality, and environmental standards, such as ISO certifications and CE marks, to ensure their equipment not only delivers exceptional performance but does so safely and sustainably. Companies at the forefront of steel recycling machinery often collaborate with academic and industrial institutions to push the boundaries of technological innovations, setting industry benchmarks that others strive to emulate.

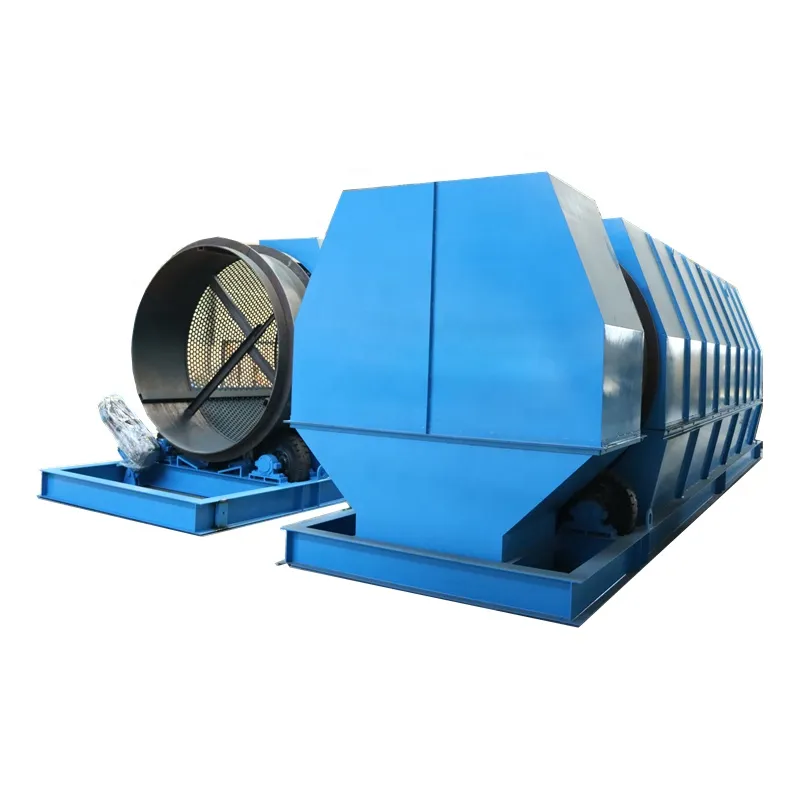

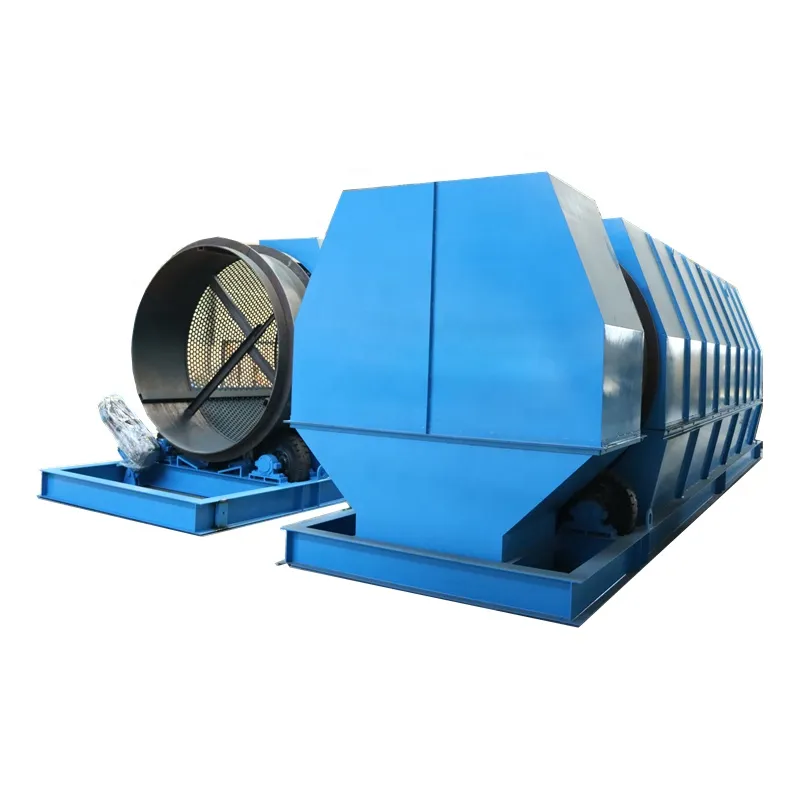

steel shredder machine

Trustworthiness, a crucial factor for businesses contemplating an investment in steel shredder machines, hinges on both product reliability and the support infrastructure provided by the manufacturer. Customer testimonials often highlight the machines’ durability and the ease of maintenance, underscoring a long-term commitment to operational efficiency. Additionally, a trustworthy supplier offers comprehensive support services that span installation, training, maintenance, and even upgradation of machinery, ensuring that clients have a seamless operational experience from day one.

Tailoring the selection of a steel shredder machine to align with specific operational goals is a strategic move that pays dividends in the long run. Key considerations should include the types and volume of materials to be processed, the operational environment, and the integration capabilities with existing waste management and recycling infrastructures. For enterprises looking to expand their recycling capabilities, modular shredders with scalable throughput capacities can provide both flexibility and growth potential.

In a climate where sustainability initiatives are gaining momentum, investing in steel shredder machinery is both an environmentally and economically sound decision. By reducing the dependency on virgin materials and lowering the carbon footprint associated with the production of new steel, these machines facilitate a circular economy model. Companies adopting these technologies are not only enhancing their eco-credentials but are also positioning themselves as leaders in innovative waste management strategies.

In conclusion, the evolution of steel shredder machines stands as a testament to the ingenuity and foresight within the recycling industry. As modern businesses strive to meet both efficiency and environmental goals, these machines emerge as indispensable assets, combining experience, expertise, authoritativeness, and trustworthiness into a powerful tool for sustainable industrial practices. Through precise engineering and unwavering commitment to quality, steel shredder machines continue to pave the way towards a cleaner, more resourceful future.