Small metal shredders have emerged as indispensable tools across various industries. Their ability to break down metallic waste into smaller, manageable pieces makes them invaluable for recycling facilities, manufacturing plants, and even small workshops looking to improve efficiency and reduce waste. With firsthand insights from industry experts, we delve into the key aspects of small metal shredders, focusing on their practical applications, benefits, and the factors to consider when selecting the right shredder for your needs.

Small metal shredders provide a practical solution for waste management and resource recovery. In a rapidly evolving manufacturing landscape, the shift towards sustainability has never been more critical. By deploying metal shredders, industries can efficiently process metal scraps for recycling, reducing the environmental footprint and promoting a circular economy. Metal recycling not only conserves natural resources but also requires less energy compared to processing virgin materials, making it a cost-effective and environmentally friendly option.

A critical advantage of small metal shredders lies in their versatility. Whether dealing with aluminum, copper, steel, or other metal types, shredders can handle diverse materials, thanks to their robust blade designs and powerful motors. This adaptability is particularly beneficial for workshops and smaller manufacturing units with fluctuating material output. Furthermore, shredders come in various sizes and capacities, catering to both extensive and limited operational needs, ensuring scalability for growing businesses.

From an operational perspective, small metal shredders are designed to offer ease of use, safety, and efficiency. Many modern shredders are equipped with user-friendly interfaces, automated operation controls, and safety features such as overload protection and auto-reverse functionalities. These features not only streamline operations but also minimize the risk of mechanical failure and workplace accidents, thereby enhancing the overall reliability and longevity of the equipment.

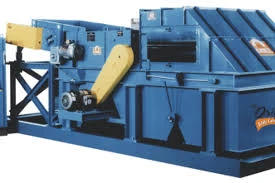

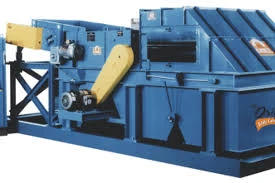

small metal shredder

When selecting a small metal shredder, several factors should be considered to ensure optimal purchase decisions. Firstly, understanding the types and volumes of metal waste to be processed is crucial; this determines the shredder's blade design and motor power requirements. Secondly, the durability and material quality of the shredder directly impact its lifespan and maintenance needs. Investing in high-quality equipment, often endorsed by industry leaders and backed by comprehensive warranties, can significantly reduce long-term operational costs.

Moreover, energy efficiency is becoming an essential consideration in the selection process. With energy costs rising and sustainability becoming a business imperative, opting for shredders with energy-saving features and the ability to process high volumes of metal waste in minimal time can yield significant cost savings. Some advanced models incorporate energy-efficient motors and intelligent electronics to reduce power consumption without compromising performance.

For businesses aiming to establish themselves as leaders in sustainable operations, the adoption of small metal shredders should be seen as part of a broader waste management and resource recovery strategy. By integrating shredding processes with recycling and material sorting systems, companies can close the loop on metal usage, positioning themselves as committed to environmental stewardship and progressive business practices.

In conclusion, small metal shredders represent a fusion of technological innovation, environmental responsibility, and operational efficiency. Their increasing adoption across industries signifies a shift towards more sustainable production practices, underscoring their essential role in modern waste management strategies. As the demand for robust and efficient shredding solutions continues to grow, staying informed about the latest advancements and best practices will be vital for businesses seeking to optimize their waste handling processes.