5 月 . 30, 2025 00:19 Back to list

(shredder machine for metal)

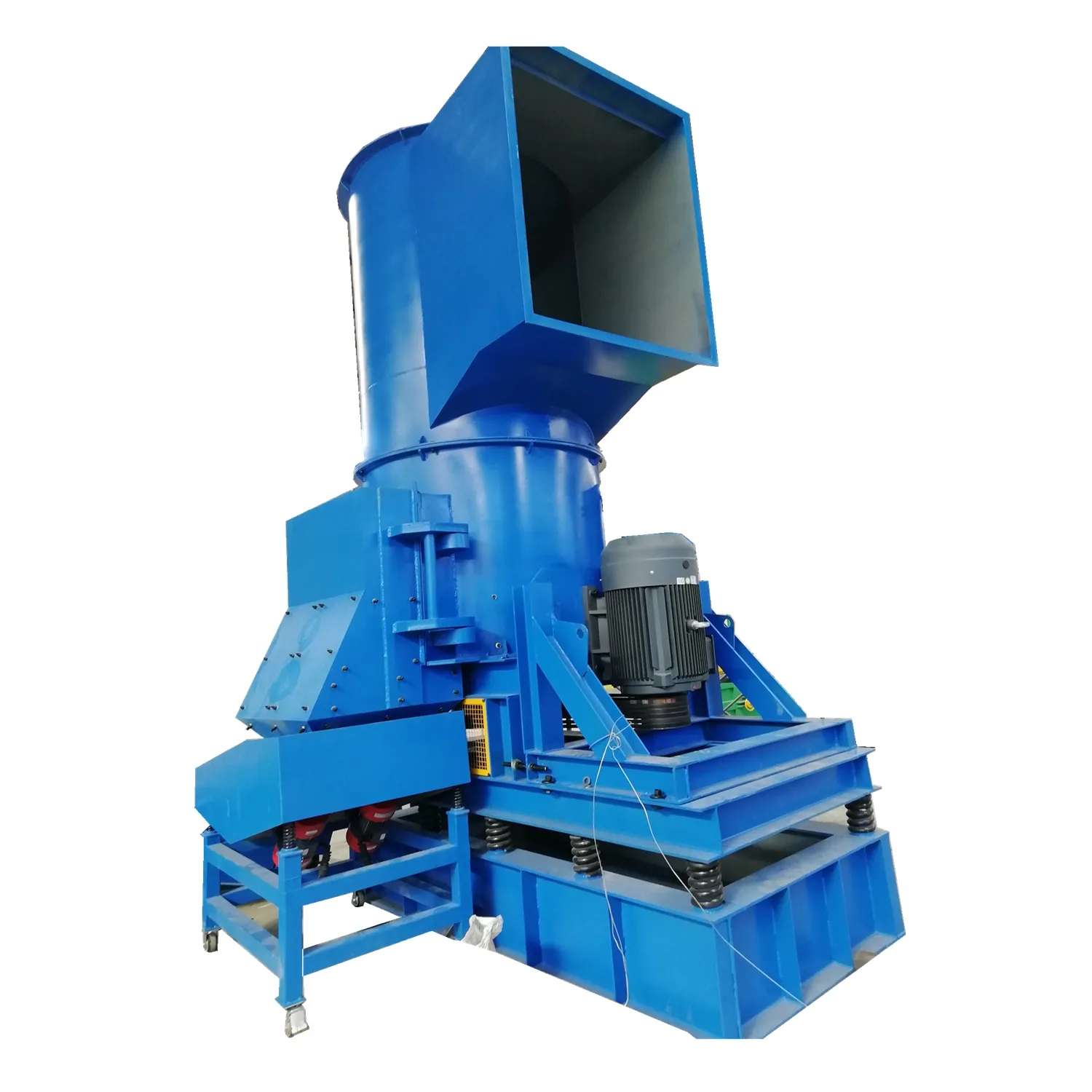

The demand for efficient metal shredder machines has surged as industries prioritize recycling and waste reduction. These machines transform bulky metal scraps into manageable fragments, optimizing resource recovery. With global metal recycling projected to grow at 5.8% CAGR until 2030, selecting the right equipment is critical. Whether you need a small metal shredder machine for sale or a heavy-duty industrial unit, understanding their capabilities ensures cost-effective operations.

Modern shredders integrate high-torque motors, hardened alloy blades, and automated safety systems. For instance, dual-shaft designs process up to 15 tons/hour, reducing energy consumption by 30% compared to single-shaft models. Features like real-time diagnostics and IoT-enabled monitoring minimize downtime, while hydraulic systems adapt to varying metal densities—from aluminum to titanium alloys.

Traditional crushing methods often result in uneven particle sizes and higher wear costs. In contrast, advanced metal scrap shredder machines deliver uniform output (10–100 mm) with 92% material purity. A 2023 study showed that shredders reduce processing costs by $18–$25 per ton compared to manual sorting. Additionally, noise levels are capped at 75 dB, meeting OSHA standards without compromising throughput.

| Brand | Model | Capacity (tons/hr) | Price Range | Maintenance Cycle |

|---|---|---|---|---|

| EcoShred | ES-3000H | 12–15 | $85,000–$110,000 | 600 hours |

| MetroPower | MP-Z45 | 8–10 | $62,000–$78,000 | 450 hours |

| Granutech | G-Force Pro | 18–22 | $145,000–$175,000 | 800 hours |

Manufacturers offer modular designs to align with unique operational requirements. For automotive scrap, shredders can be fitted with magnetic separators to recover ferrous metals at 99.5% efficiency. Electronics recyclers often opt for finer blade configurations to handle circuit boards and copper wires. Customizable feed hoppers and discharge systems accommodate facilities with spatial constraints.

A Midwest recycling plant reported a 40% increase in output after installing a heavy metal shredder machine paired with AI-driven sorting. Another case involved a European contractor reducing labor costs by 55% by automating scrap processing. Such systems typically achieve ROI within 14–18 months, depending on volume and metal prices.

Long-term savings, regulatory compliance, and sustainability goals justify the metal scrap shredder machine price. With landfill costs rising by 7% annually in the U.S., shredders mitigate waste disposal expenses. Moreover, recycled metals retain 95% of their original properties, making them indispensable for circular economy initiatives. Partnering with certified suppliers ensures access to warranties and technical support.

(shredder machine for metal)

A: Small metal shredder machines are available through industrial equipment suppliers, specialized recycling machinery retailers, and online marketplaces like Alibaba or eBay. Always verify the seller’s credibility and warranty terms before purchasing.

A: Heavy metal shredder machines are used in scrap recycling, automotive manufacturing, and waste management industries. They efficiently process large volumes of metal waste, such as cars, appliances, and industrial scrap.

A: Prices depend on shredding capacity, motor power, material durability, and brand reputation. Additional costs may include customization, shipping, and installation services.

A: Regularly lubricate moving parts, inspect blades for wear, and clear jams promptly. Follow the manufacturer’s maintenance schedule and use genuine replacement parts.

A: Budget-friendly models may lack durability for heavy-duty tasks. For industrial operations, prioritize machines with robust construction, higher horsepower, and warranties to ensure reliability.

Latest news

Unveiling the Power of Eddy Current Separator

NewsSep.25,2024

Transform Your Home Recyclin:home metal shredder

NewsSep.25,2024

The Future of Waste Management with Recycling Line Picker

NewsSep.25,2024

The Benefits of a Metal Recycling Plant

NewsSep.25,2024

Revolutionize Material Separation with Onwang Technology

NewsSep.25,2024

Innovative Waste Management: Unveiling the MSW Sorting Plant

NewsSep.25,2024