5 月 . 30, 2025 00:18 Back to list

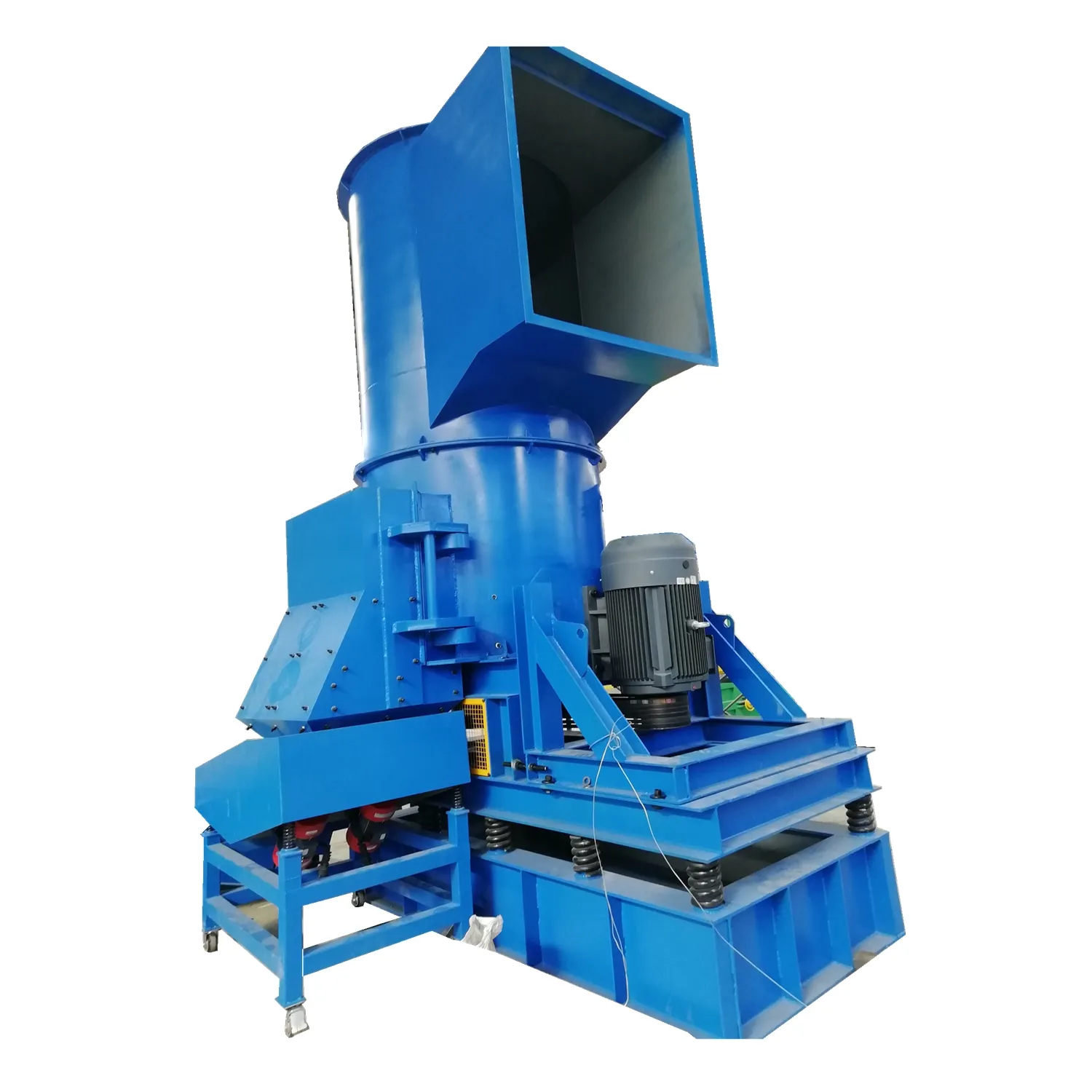

(construction waste crusher)

Global construction waste exceeded 2.2 billion tons in 2023, with only 23% being properly recycled. This alarming statistic drives demand for construction waste crusher

s capable of processing 50-800 tons/hour. Modern shredders reduce landfill dependency by 68% while recovering 92% of reusable aggregates, according to the International Recycling Council.

Third-generation crushers now integrate AI-powered load detection, automatically adjusting rotor speeds between 650-1400 RPM. Key advancements include:

| Brand | Power (kW) | Throughput (t/h) | Noise Level | Maintenance Interval | Price Range |

|---|---|---|---|---|---|

| EcoCrush Pro | 160 | 420 | 72 dB | 1,200h | $185K-$220K |

| ShredMax X7 | 200 | 580 | 68 dB | 1,500h | $240K-$275K |

| UrbanGrind C3 | 132 | 320 | 75 dB | 800h | $155K-$190K |

High-density urban projects require compact shredders (footprint <35m²) with dust suppression, while highway contractors prioritize mobile units achieving 12km/h relocation speeds. Modular configurations enable rapid switch between concrete (Mohs 5-7) and mixed debris processing.

Singapore’s Tuas Nexus facility processes 1.2 million tons/year using 12 shredders, achieving 98% material recovery. In Berlin, mobile crushers reduced demolition transport costs by €47/ton during the Potsdamer Platz redevelopment.

Average payback periods:

Fuel consumption benchmarks show hybrid models cutting diesel usage by 41% versus traditional units.

Next-gen debris shredders now integrate with BIM systems, automatically adjusting processing parameters based on material composition data. This innovation reduces sorting time by 55% while increasing recycled aggregate quality to meet ASTM C33 standards.

(construction waste crusher)

A: A construction waste crusher breaks down bulky debris like concrete, bricks, and asphalt into smaller, reusable granules. It simplifies recycling and reduces landfill dependency by converting waste into raw materials for new projects.

A: A shredder uses rotating blades to tear apart materials like wood, metal, or plastic, while a crusher applies compressive force to crush hard debris. Shredders are ideal for mixed or softer waste, whereas crushers handle dense, rigid materials.

A: Construction debris shredders handle materials such as drywall, insulation, plastics, and light metals. They’re designed for versatile processing, enabling efficient volume reduction and preparation for recycling or disposal.

A: Yes, modern crushers include safety features like emergency stops, dust suppression systems, and reinforced hoppers. Operators must follow guidelines, wear protective gear, and ensure machinery is maintained for safe use.

A: Regular lubrication, blade sharpening/replacement, and inspection of belts or motors are essential. Proper maintenance ensures longevity, optimal performance, and minimizes downtime during waste processing operations.

Latest news

Unveiling the Power of Eddy Current Separator

NewsSep.25,2024

Transform Your Home Recyclin:home metal shredder

NewsSep.25,2024

The Future of Waste Management with Recycling Line Picker

NewsSep.25,2024

The Benefits of a Metal Recycling Plant

NewsSep.25,2024

Revolutionize Material Separation with Onwang Technology

NewsSep.25,2024

Innovative Waste Management: Unveiling the MSW Sorting Plant

NewsSep.25,2024