9 月 . 12, 2024 15:28 Back to list

How does an eddy current separator work? Eddy current separation (ECS) is a sorting technique that uses different electrical conductivity of substances, and its sorting principle is based on two important physical phenomena:

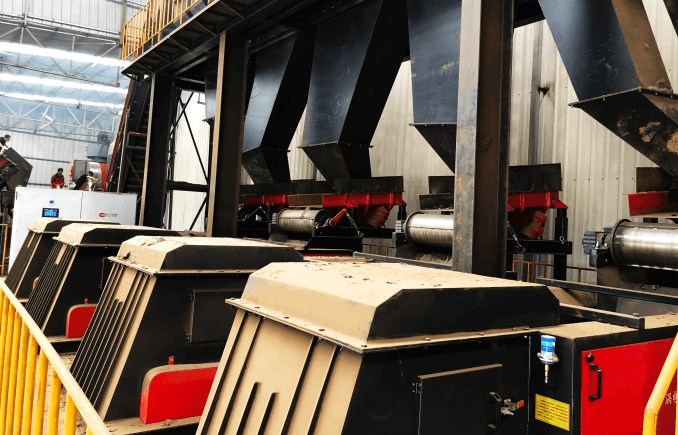

The principle of eddy current separation introduced in this article is shown in the Figure below.

A rotating drum wrapped by a permanent magnet (High Performance NdFeB Magnets) produces a alternating magnetic field. When a metal with conductive properties passes through the magnetic field, an eddy current will be generated in the metal. The eddy current itself generates an alternating magnetic field, which is opposite to the direction of the magnetic field generated by the magnet rotor, that is, it generates a repulsive force (Lorentz force) on the metal, which separates the metal from the material flow and achieves the purpose of separation.

The repulsive force generated by eddy current on the conductor is related to the strength of the magnetic field change, the conductivity, density, area and shape of the conductor.

For different non-ferrous metal materials, the repulsion force is related to the composition characteristics, and the composition force can be expressed as:

F (compositional force) = mσ/ρs

In the equation:

The following table lists the specific conductance (σ/ρ) factor values for some metals. From the value of σ/ρ, the magnitude of the repulsion force and the difficulty of sorting can be judged. Generally, high conductivity and low density materials suffer the most repulsion.

| Metal | Al | Zn | Sn | Cu | Brass |

|---|---|---|---|---|---|

| σ/ρ | 14 | 2.4 | 1.2 | 6.7 | 1.7 |

| Metal | Mg | Au | Pb | Ag | Ni |

| σ/ρ | 12.9 | 2.2 | 0.4 | 6 | 1.4 |

In 1889, the American inventor Edison applied for a patent for an alternating magnetic field eddy current separator, which was used to separate nonferrous metals and non-metals. Early sorting equipment including:

With the development of permanent magnetic materials, the research & development of permanent magnetic roll eddy current separator have appeared one after another. From the late 1980s to the early 1990s, Germany and the United States successively developed the NdFeB permanent magnet roller eddy current separator (PMRECS), which was put on the market by the American Eriez magnetic company and the German Wagner company.

It can be seen from the above analysis that the core of the eddy current sorting equipment is the sorting system, and the magnetic rotor is the heart of the sorting system. The generation of eddy currents uses permanent magnets instead of coils, which greatly reduces the volume of the magnetic rotor. Simultaneously using the frequency converter to change the rotation frequency can produce eddy currents with different strength.

The advantage of the eccentric magnetic rotor is to prevent iron particles from infiltrating between the belt and the motor and cannot be discharged, when the traditional concentric magnetic rotor rotates, causing the beating friction heat to damage the belt and the hub. The eccentric magnet system can adjust the center position of the magnetic pole according to different materials, so that the non-ferrous metals can jump away at the most suitable angle to obtain the best sorting effect.

The eddy current sorting equipment is particularly suitable for the separation between high-conductivity and low-density substances and low-conductivity and high-density substances, and between conductors and non-conductors. Ferromagnetic substances cause high heat damage to equipment due to eddy currents. The processing objects of eddy current sorting are scrap copper (aluminum) power cables, aluminum products, automotive scrap, non-ferrous metal debris, printed circuit board gray ballast, non-ferrous metal-containing glass ballast, electronic waste, polymetal (Al, Cu , Pb, Zn) mixture, cast copper (aluminum) sand and ballast.

Municipal solid waste treatment

The reduction, harmlessness and recycling of solid waste are the three major technical policies proposed by our country in the mid-1980s to control solid waste pollution. The treatment of municipal solid waste is not only a very important environmental protection measure, but also an important means of resource recovery. In the general comprehensive treatment process of municipal solid waste, for the material after secondary air separation, the non-ferrous metals and heavy organic matter in the waste can be separated and recovered by the eddy current separation method

Treatment of industrial solid waste

Many industrial wastes can be treated with eddy current sorting techniques. The use of eddy current sorting to treat waste cars is very common in developed countries. The treatment of car scarps is mainly to recycle the scrap steels (about 80% of the total weight). The value of scrap steel depends on its purity. If it contains aluminum, copper, zinc, etc., it will seriously affect its value, so these components need to be removed before smelting.

Other industrial wastes such as the recovery of non-ferrous metals in discarded electronic components, the recovery of non-ferrous metals in coal ash residues, and the recovery of aluminum in aluminum smelting waste residues, etc., can be all achieved by eddy current separation.

Purification of molding sand in aluminum and non-ferrous metal casting industry

In the aluminum and non-ferrous metal casting industry, the molding sand will be gradually contaminated by metal residues during use, which will affect the quality of the casting. The eddy current separation method can effectively separate the molding sand and metal residues, which provides conditions for the reuse of molding sand.

Latest news

Unveiling the Power of Eddy Current Separator

NewsSep.25,2024

Transform Your Home Recyclin:home metal shredder

NewsSep.25,2024

The Future of Waste Management with Recycling Line Picker

NewsSep.25,2024

The Benefits of a Metal Recycling Plant

NewsSep.25,2024

Revolutionize Material Separation with Onwang Technology

NewsSep.25,2024

Innovative Waste Management: Unveiling the MSW Sorting Plant

NewsSep.25,2024