In the evolving landscape of industrial waste management, the twin shaft shredder has emerged as a pivotal solution for businesses aiming to boost operational efficiency and sustainability. Known for their robustness and versatility, these machines represent a blend of engineering prowess and environmental consciousness, making them essential in recycling and waste processing sectors.

A twin shaft shredder operates by using two parallel shafts that rotate towards each other, effectively crushing and shredding materials between the blades mounted on each shaft. This design facilitates the breakdown of a wide range of materials, from plastics and metals to organic waste and textiles, with impressive precision and energy efficiency.

One of the primary advantages of twin shaft shredders is their ability to handle a variety of materials without the need for extensive pre-sorting. This feature alone significantly reduces labor costs and improves processing time, catering to businesses where throughput speed is crucial. By accommodating different material types, these shredders minimize downtime that might occur when switching between batches, thereby optimizing productivity.

From an engineering perspective, twin shaft shredders are designed to withstand rigorous conditions, making them suitable for heavy-duty operations. The robust construction ensures longevity and reliability, even when processing tough, abrasive materials. This aspect is particularly valuable for businesses that operate in harsh environments or require high-volume processing capabilities.

Expertise in manufacturing twin shaft shredders has seen significant advancements, with many manufacturers incorporating smart technology into their designs. Features such as automated load sensing, programmable logic controllers (PLCs), and advanced hydraulic drive systems enhance operational control and safety. These innovations not only result in a more consistent output but also provide operators with detailed feedback on operational status, aiding in preventive maintenance and reducing the risk of unscheduled downtime.

Furthermore, twin shaft shredders offer scalable solutions suitable for businesses of varying sizes, from small recycling firms to large-scale industrial waste processors. The modular design options mean that companies can tailor the shredder setup to meet specific capacity requirements, while simultaneously allowing for future expansions.

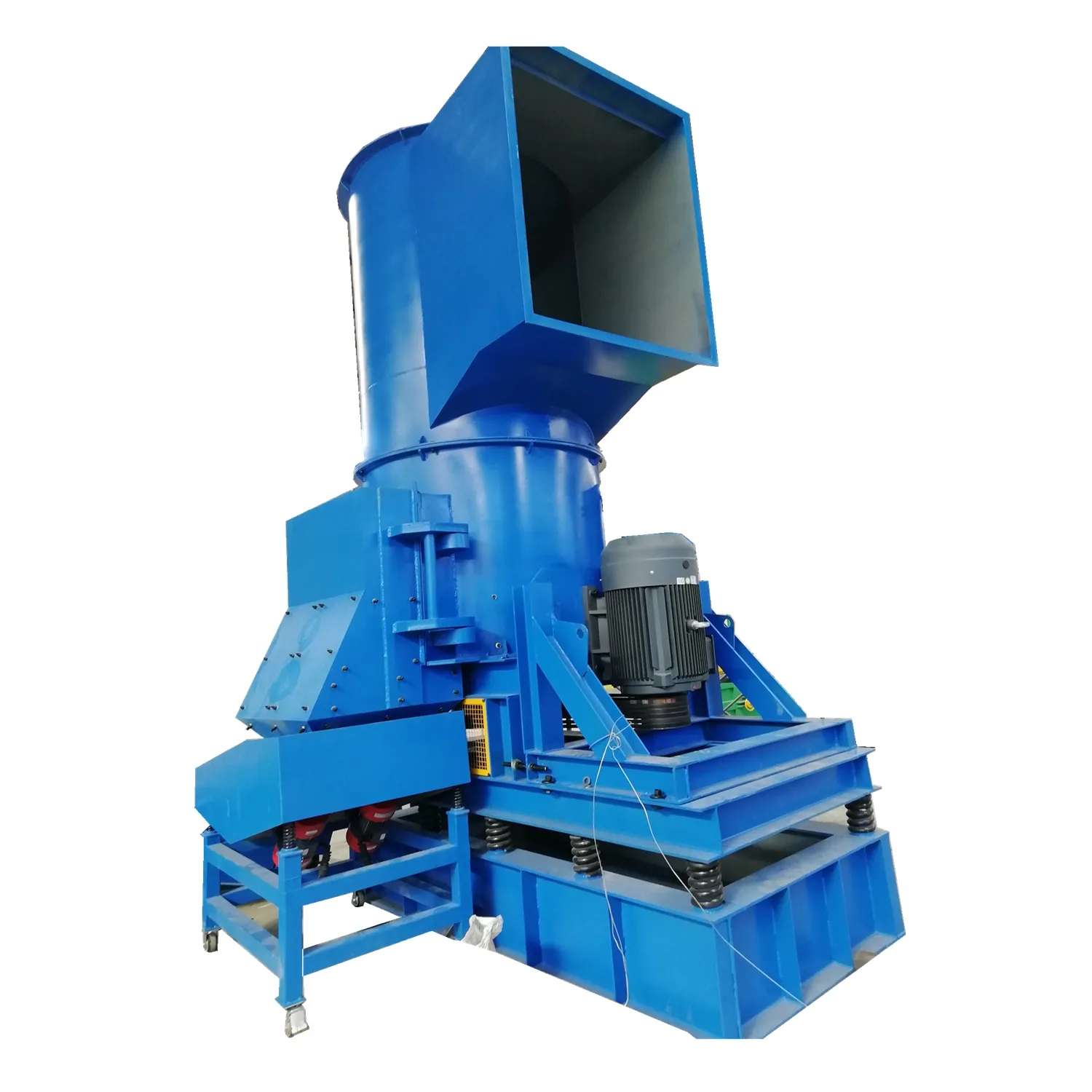

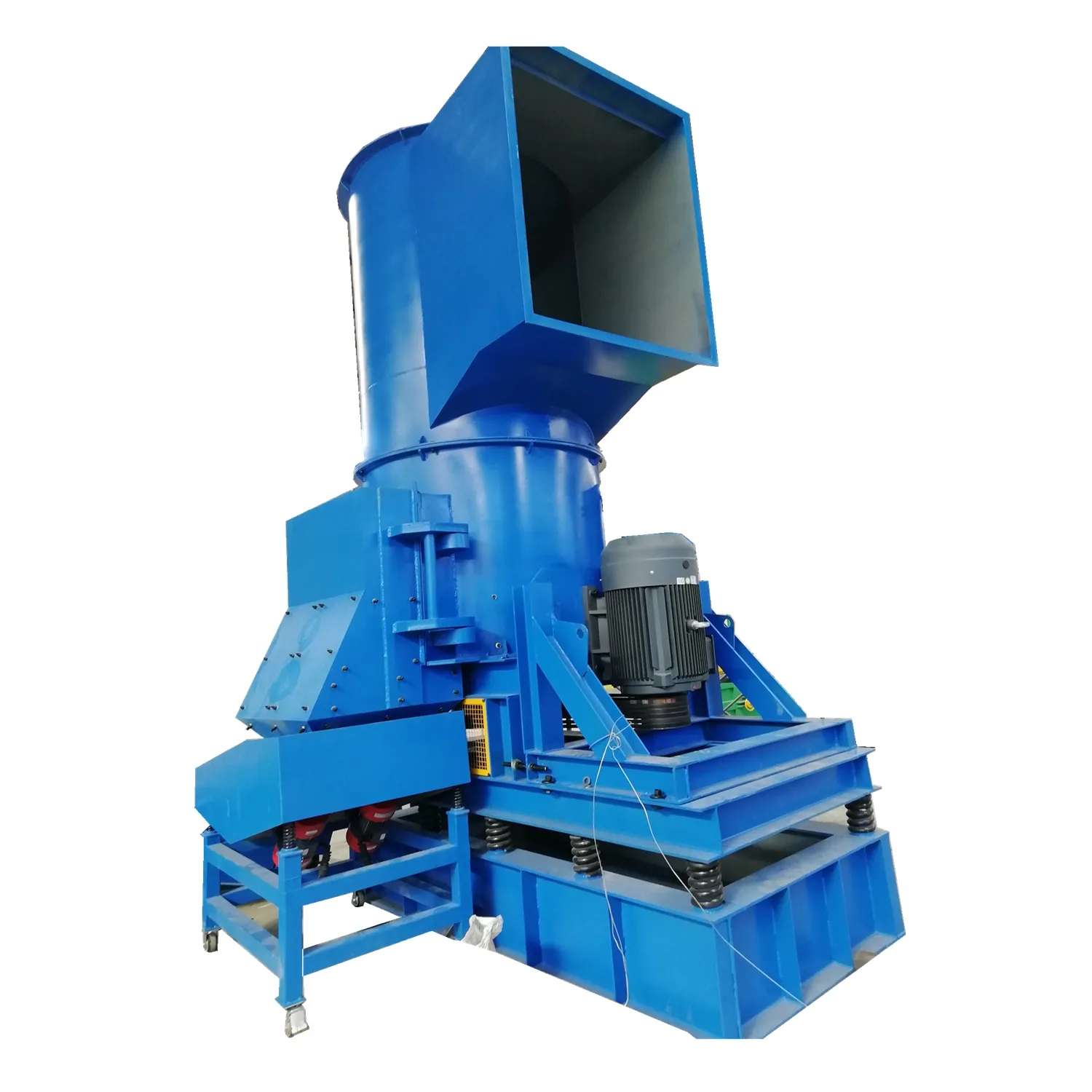

twin shaft shredder

In terms of environmental impact, twin shaft shredders contribute significantly to sustainability efforts. By promoting material recovery and reducing landfill usage, these machines play a vital role in achieving waste reduction goals. They transform waste materials into recyclable commodities, facilitating the circular economy and helping companies comply with increasingly stringent environmental regulations.

Experts in the field emphasize the importance of selecting the right twin shaft shredder tailored to specific operational needs. Factors to consider include the type and volume of material to be processed, desired output size, and available facility space. Consultations with manufacturers and thorough assessments of current and future processing needs ensure that the chosen machinery delivers optimal performance and return on investment.

The dual-shaft shredding technology also enhances safety within industrial operations. With carefully designed safety mechanisms, such as emergency stop features and protective covers, these machines minimize the risk of accidental injuries. Operators can thus manage the shredding process with confidence, knowing that industry standards of safety and operational integrity are upheld.

Trustworthiness in the twin shaft shredding market comes from recognized manufacturers that continuously invest in research and development. Companies that prioritize engineering innovation, rigorous product testing, and customer feedback establish themselves as trustworthy partners in the waste management sector. Buyers should prioritize working with manufacturers that offer comprehensive support services, including machine commissioning, operator training, and after-sales technical assistance.

Overall, twin shaft shredders signify more than just a method of material reduction—they represent a leap towards innovative waste management strategies that combine efficiency and sustainability. For businesses seeking to enhance their waste processing capabilities, adopting a twin shaft shredder is not just a purchase; it is an investment in technology that promises durability, adaptability, and improved environmental stewardship.