Industrial efficiency and materials management have significantly evolved, and at the forefront of this evolution stands the swarf shredder. This indispensable piece of equipment not only enhances operational efficiency but also supports sustainable manufacturing practices. It is crucial for companies to engage with cutting-edge tools like swarf shredders to meet modern demands in waste management and resource optimization. With growing environmental consciousness and tighter regulations, understanding the pivotal role of swarf shredders in industry has never been more important.

Swarf shredders redefine the way industries manage metal byproducts that accumulate during machining processes. These shavings, also known as ‘swarf’, are often left unutilized, thus failing to contribute to the value chain. By investing in a swarf shredder, businesses can convert this waste into reusable materials, thereby minimizing wastage. The shredded swarf is easier to transport, handle, and repurpose, aligning with circular economy principles.

The integration of swarf shredders into production processes exhibits expertise in waste management and environmental compliance. As regulations on waste disposal become more rigorous, industries face mounting pressure to find viable waste management solutions. Swarf shredders not only help meet regulatory standards but also position companies as leaders in sustainable practices. This equipment showcases a company’s commitment to reducing its carbon footprint by recycling materials that traditionally ended up in landfills.

Authoritativeness in the use of swarf shredders is reflected in enhanced product quality and operational efficiency. By shredding swarf in-house, companies maintain better control over their production processes. This control translates into significant cost savings, as recycled materials reduce the need to purchase new raw materials. The consistency of shredded swarf also improves the quality of end products, ensuring that recycled metal can seamlessly reintegrate into the manufacturing cycle without compromising product integrity.

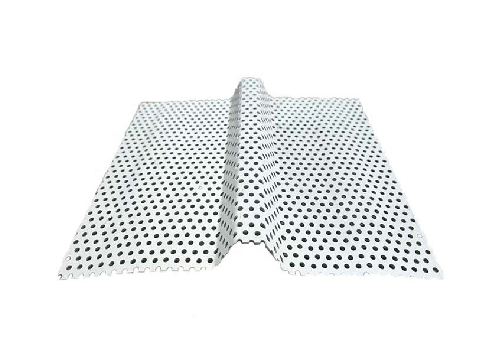

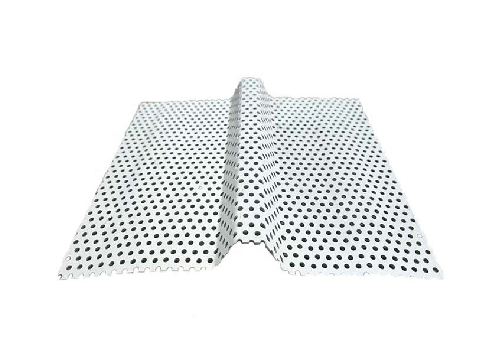

swarf shredder

Trustworthiness is garnered through demonstrable success and transparency in waste management practices. Companies utilizing swarf shredders can showcase tangible environmental impacts, offering an edge in industries focused on sustainability. Transparency about recycling processes fosters trust with clients and partners, ensuring that business relationships are strengthened by mutual dedication to quality and environmental responsibility.

By sharing real-world experiences and success stories, companies can highlight the swarf shredder's tangible benefits. For instance, a case study of a manufacturing firm that integrated a swarf shredder revealed a 30% reduction in raw material costs and a 40% decrease in waste collection expenses. Such examples resonate with companies contemplating the adoption of this technology. This compelling evidence underscores the significant return on investment and operational improvements gained from swarf shredders.

In conclusion, embracing swarf shredders denotes a proactive stance toward modern industrial challenges. The equipment's capacity to convert waste into resources will continually enhance its relevance across various sectors. The decision to include a swarf shredder is not merely an operational adjustment but a strategic move toward sustainability and efficiency. Businesses investing in swarf shredders will not only boost their reputation but will also pave the way for a more sustainable future.