In the world of modern industrial applications, the steel shredder is a pivotal piece of machinery that exemplifies both engineering prowess and manufacturing efficiency. As industries look to recycle and manage waste effectively, understanding the intricacies of a steel shredder can set one apart as a leader in sustainable practices.

Steel shredders are no ordinary machines; they epitomize heavy-duty operations and precision. Designed to systematically reduce metallic waste into manageable pieces, these shredders are a cornerstone in the recycling process, particularly in the automotive and construction sectors. From dismantling retired vehicles to reprocessing construction debris, the role of a steel shredder is indispensable.

Experience tells us that operating a steel shredder requires a specialized skill set. Operators must ensure that the machinery is consistently maintained to prevent wear and tear that could lead to operational downtime. Regular maintenance checks safeguard the equipment against harsh operating conditions, thus extending the shredder's lifespan and ensuring uninterrupted productivity. Experienced operators know the importance of balancing throughput and maintenance activities to maximize efficiency without compromising on quality.

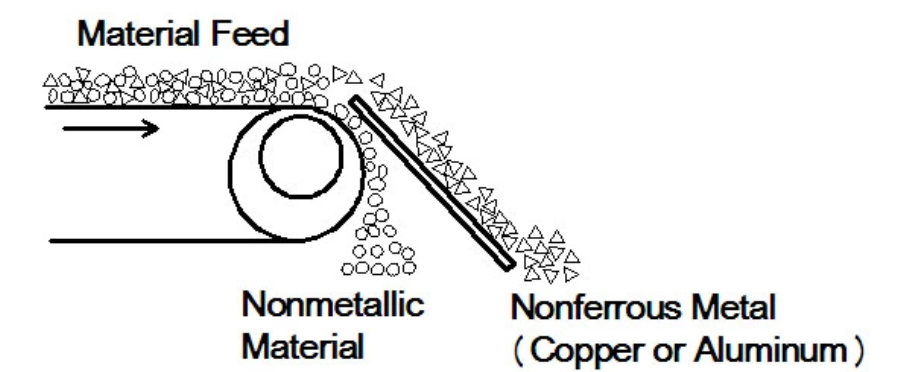

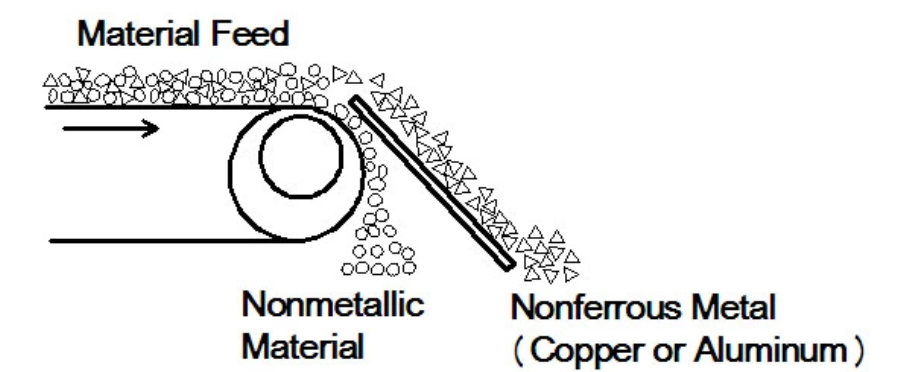

The expertise in leveraging a steel shredder comes in understanding the varying grades of steel and how each responds to the shredding process. Materials can vary widely in terms of thickness, toughness, and composition. A thorough grasp of these characteristics allows an operator to optimize the settings of the shredder, adjusting parameters such as blade speed and motor power to ensure clean, efficient cuts. Precision in these adjustments is crucial to maintaining the quality of the shredded steel while minimizing energy consumption.

steel shredder

Authoritativeness in the domain of steel shredding is demonstrated by a commitment to innovative technologies and adherence to regulatory standards. Progressive firms are integrating technologies such as automated controls and sensors that enhance the operational accuracy of shredders. These advancements not only elevate the performance of the machinery but also promote safety—a vital aspect when dealing with heavy machinery. Taking leadership in these innovations positions companies as industry authorities, setting benchmarks for efficiency and safety.

Creating a trustworthy steel shredding operation involves more than just technical capability—it extends to environmental responsibility. Customers and partners alike assess trustworthiness based on how companies manage their environmental footprint. Shredding steel responsibly reduces the volume of waste dispatched to landfills, supporting sustainability efforts. Transparency in operational practices and showcasing genuine efforts in eco-friendly initiatives reinforces the credibility of firms engaging in steel shredding.

In summary, the steel shredder is far beyond just industrial equipment—it is an embodiment of experience, expertise, authoritativeness, and trustworthiness. For businesses aiming to excel in steel recycling and waste management, mastering these dimensions not only enhances their operational capabilities but also fortifies their reputation in the industry. As market dynamics evolve, forward-thinking organizations that prioritize these aspects will discover new pathways to growth, efficiency, and sustainability.