Finding the right small industrial shredder for sale is crucial for businesses that handle sensitive or bulk materials. These machines not only reduce the size of various materials but also ensure the safe disposal of them, making them indispensable in industries ranging from manufacturing to waste management. Selecting the perfect shredder involves understanding their workings, technical specifics, application domains, and key purchase considerations—all of which we'll outline in this comprehensive guide.

Small industrial shredders are engineered to break down bulk material efficiently and can handle different materials depending on the type of shredder. Whether dealing with paper, plastics, or wood, selecting a shredder designed for specific materials ensures maximal efficiency and prolonged equipment lifespan. The designs range from single-shaft shredders, which are ideal for materials that require consistent particle size reduction, to dual-shaft shredders perfect for tougher materials because of their higher torque capability.

Expert operators emphasize the importance of understanding the capacity and throughput of the shredder. Capacity, often measured in pounds per hour, dictates the amount of material that can be processed reliably within a given timeframe. Throughput, on the other hand, concerns the volume of material processing per hour. Both figures are pivotal in aligning the machine's performance with operational needs. Overestimating your shredding requirements leads to unnecessary expenses, while underestimating can result in bottlenecks that slow down operations.

From an expertise standpoint, the shredder’s blade configuration, rotational speed, and motor power significantly influence its effectiveness. High-quality, durable blades reduce maintenance frequency and enhance mechanical reliability. For example, in cutting metals, specialized blades with a higher wear resistance are recommended due to the abrasive nature of metal materials. Motor power impacts the machine’s ability to operate smoothly under heavy loads, so matching motor specifications with intended use cases is critical.

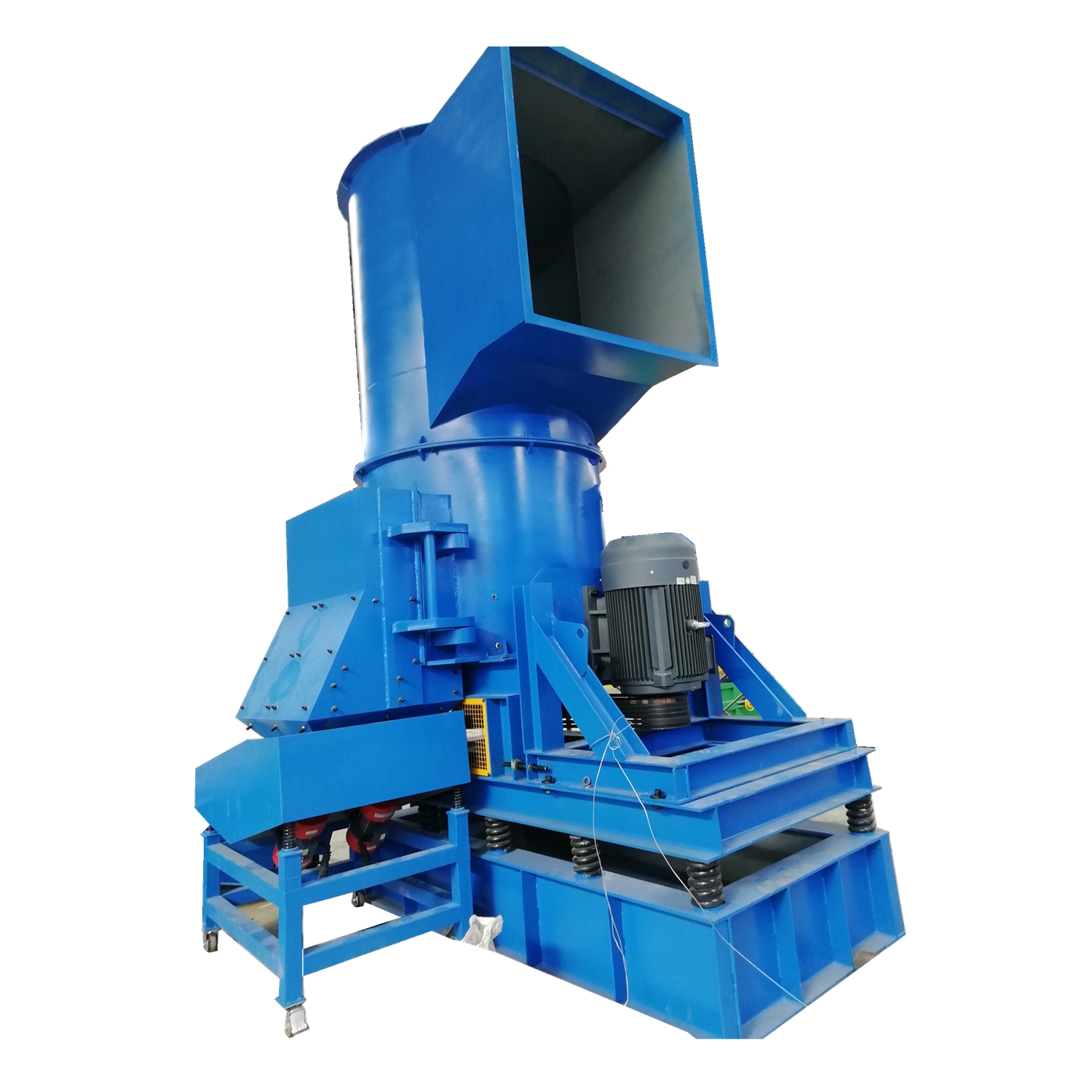

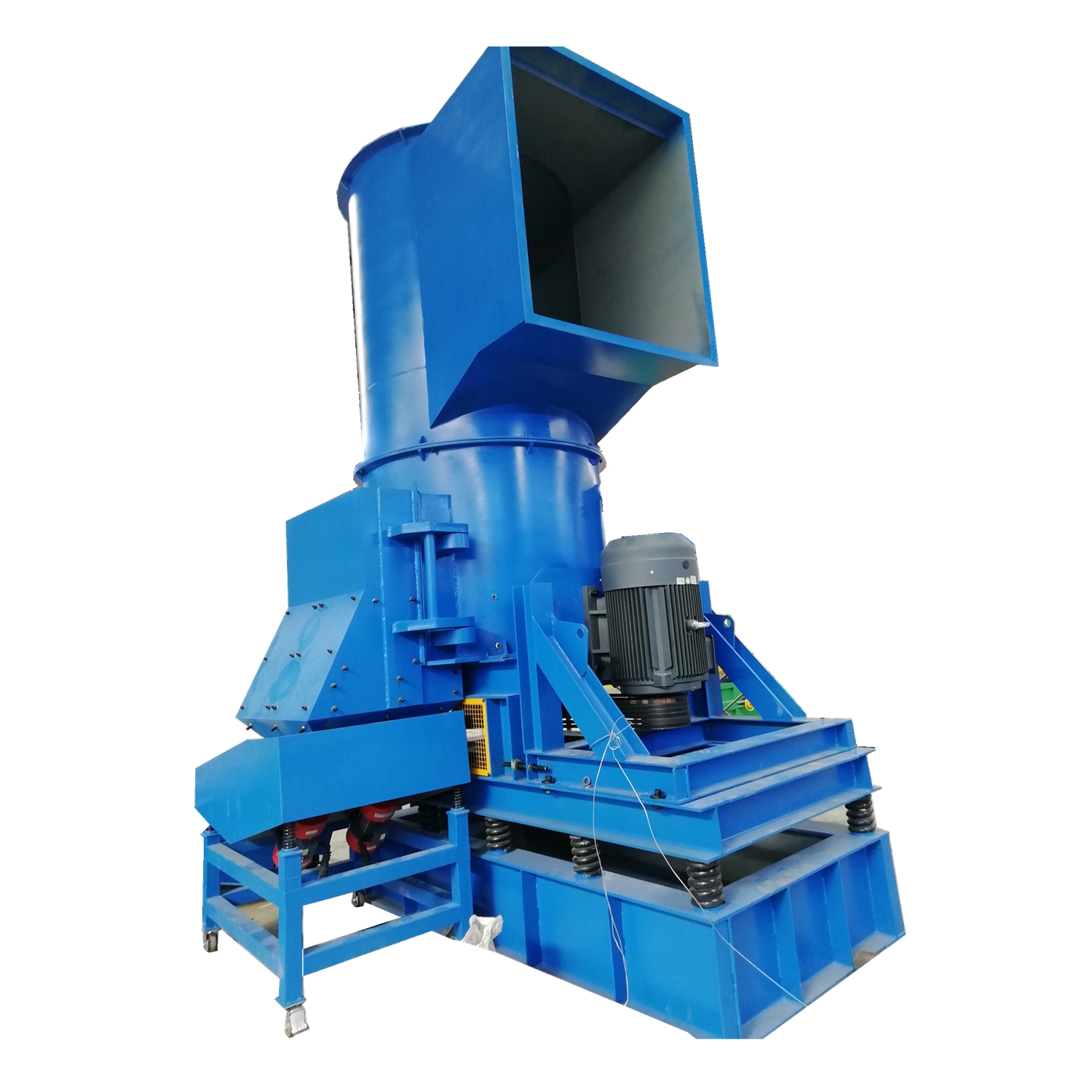

small industrial shredder for sale

Authoritativeness in the selection process extends through the manufacturer's reputation and warranty offerings. A well-regarded manufacturer not only guarantees quality but also provides reliable customer support and access to parts. Review the warranty carefully—longer warranty periods generally indicate greater confidence in the product by the manufacturer. Furthermore, check if the manufacturer offers post-purchase support and technical assistance. This support is invaluable when addressing technical issues that might arise, keeping downtime to a minimum.

Trustworthiness comes from third-party reviews and certifications. Seek out reviews and testimonials from other buyers in your industry to gauge your options' performance from a practical, real-world perspective. Certifications from recognized bodies assure compliance with safety and operational standards. For instance, obtaining shredders with ISO certifications can assure adherence to international standards of quality and reliability.

Practical experience highlights the importance of considering operational noise and maintenance. Choosing a shredder with noise-dampening features can create a more pleasant working environment—particularly in enclosed spaces. Moreover, easy access to components and clear maintenance guidelines are essential for extending the lifespan of the shredder and minimizing downtime.

In conclusion,

investing in a small industrial shredder demands a balance between technical specifications, application needs, and manufacturer trust. By focusing on these aspects, businesses can ensure they select the most suitable shredder that offers reliability, efficiency, and long-term economic benefit. This guide positions you to make an informed decision that harmonizes operational efficiency and product durability, thus fortifying your business’s material handling and waste management capabilities.