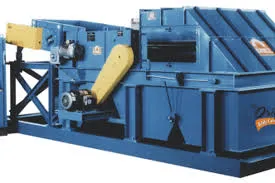

Unveiling the Future of Material Processing The Single Shaft Shredder

In the ever-evolving landscape of material processing, efficiency and innovation stand as the pillars of industry advancement. Among the powerful tools propelling this progress is the single shaft shredder, a machine designed with precision to handle diverse materials with ease and reliability. Leveraging cutting-edge technology, this equipment not only enhances productivity but also offers unmatched experience in waste management and recycling.

Renowned for its utility across various sectors, the single shaft shredder is a testament to engineering expertise. This robust machine is engineered to deliver superior performance in shredding tasks, accommodating materials ranging from plastic and wood to metals and textiles. Its unique design facilitates consistent operation with minimal downtime, ensuring that industries can maintain seamless production flow while reducing operational costs.

What sets the single shaft shredder apart is its seamless integration of professional engineering and innovative features.

One standout is its adjustable rotor speed, which allows operators to tailor the shredding intensity according to the material type, thereby optimizing efficiency. Furthermore, the durable rotor blades are crafted from high-strength steel, ensuring longevity and reducing the frequency of maintenance — a vital consideration for industrial users seeking maximum uptime.

single shaft shredder

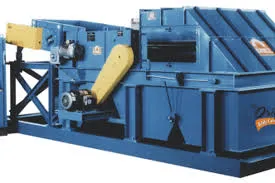

For those in search of authoritative insight into the shredding industry, the single shaft shredder embodies trustworthiness through its compliance with international safety standards. The inclusion of smart sensors allows for real-time monitoring of operational parameters, enhancing safety and operational oversight. These sensors can predict potential machine faults, allowing for proactive maintenance and minimizing unexpected downtime, thus safeguarding production schedules.

From an environmental perspective, the single shaft shredder is environmentally conscious, supporting sustainable processing practices. By efficiently reducing material size for recycling and repurposing, this equipment significantly diminishes landfill contributions. Users can trust in its eco-friendly design to align with corporate sustainability goals, thus reinforcing brand reputation and customer trust.

Drawing from extensive real-world experience, the feedback from industries utilizing single shaft shredders is overwhelmingly positive. These machines not only provide the durability and efficiency required for demanding environments but also exhibit the versatility necessary to adapt to various material processing needs. Companies report enhanced throughput and a noticeable reduction in operational strain, affirming the single shaft shredder's role as a reliable asset in their production arsenal.

Ultimately, as industries continually seek out improved methods of material management, the single shaft shredder emerges as a paramount choice, thanks to its blend of expertise-driven design, authoritative reliability, and eco-conscious operation. Its integration into manufacturing and recycling facilities signifies a step toward a more efficient and sustainable future, demonstrating that with the right technology, industries can excel in both performance and environmental stewardship.