Shredder scrap prices have become a focal point in the recycling and waste management industries due to their direct impact on profitability and market dynamics. As a seasoned expert with years of experience in the field, I will delve into the critical factors that affect these prices, emphasizing transparency and professional insights to help businesses and individuals make informed decisions.

One of the prime determinants of shredder scrap prices is the quality and type of materials processed. Ferrous metals, non-ferrous metals, and other mixed composites each hold different market values, influenced by global supply and demand. High-quality ferrous scrap, for instance, often commands a competitive price due to its widespread use in manufacturing industries. Meanwhile, non-ferrous metals like aluminum and copper, owing to their innate properties and recyclability, usually fetch higher prices but can be more volatile.

Market demand is another substantial influencer. Economic periods that boost industrial activities usually lead to increased demand for recycled materials, thereby elevating the scrap prices. Conversely, economic slowdowns or geopolitical tensions can lead to a surplus of supply, driving prices down. Staying informed about macroeconomic trends and global market forecasts can provide businesses with an edge in predicting price fluctuations and making strategic decisions accordingly.

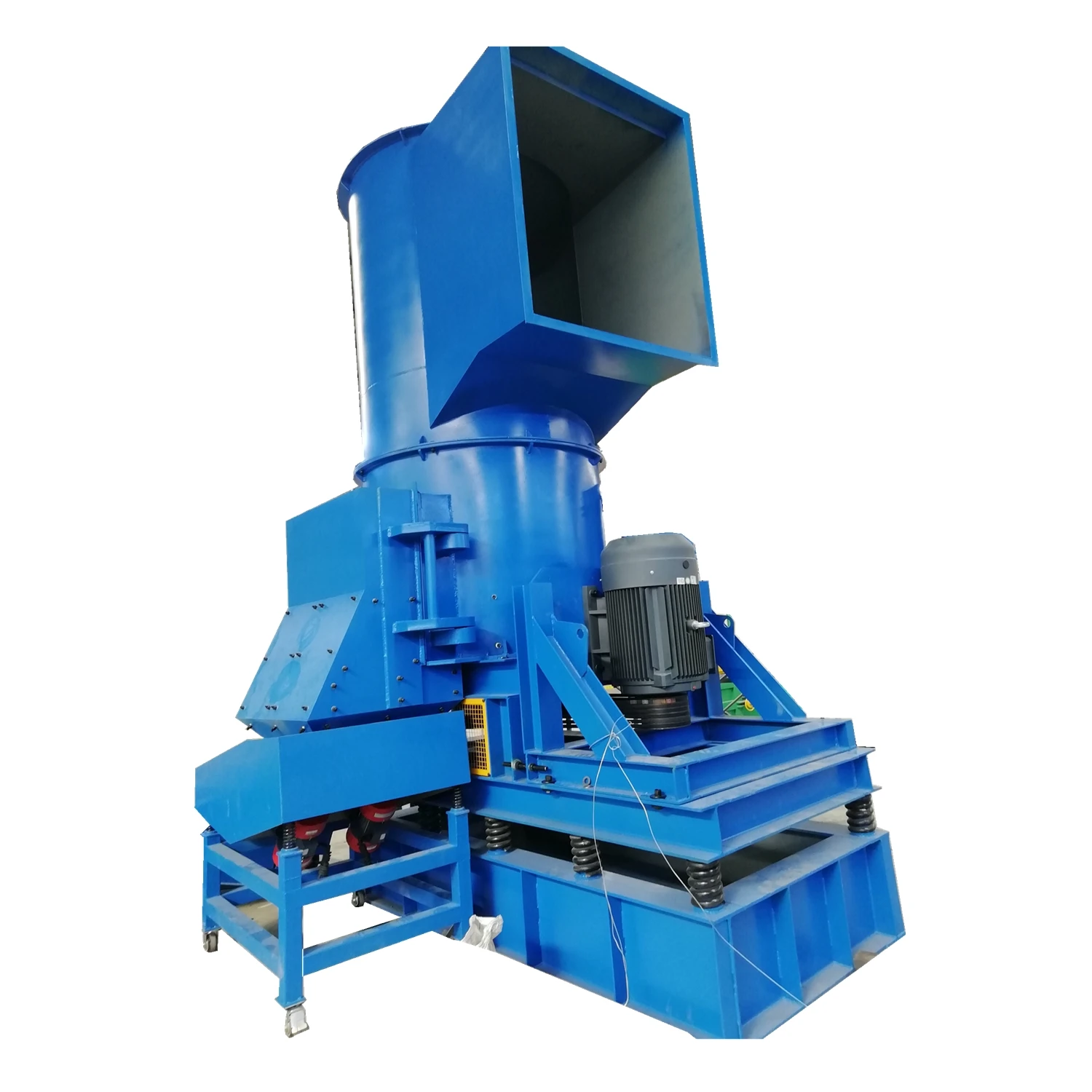

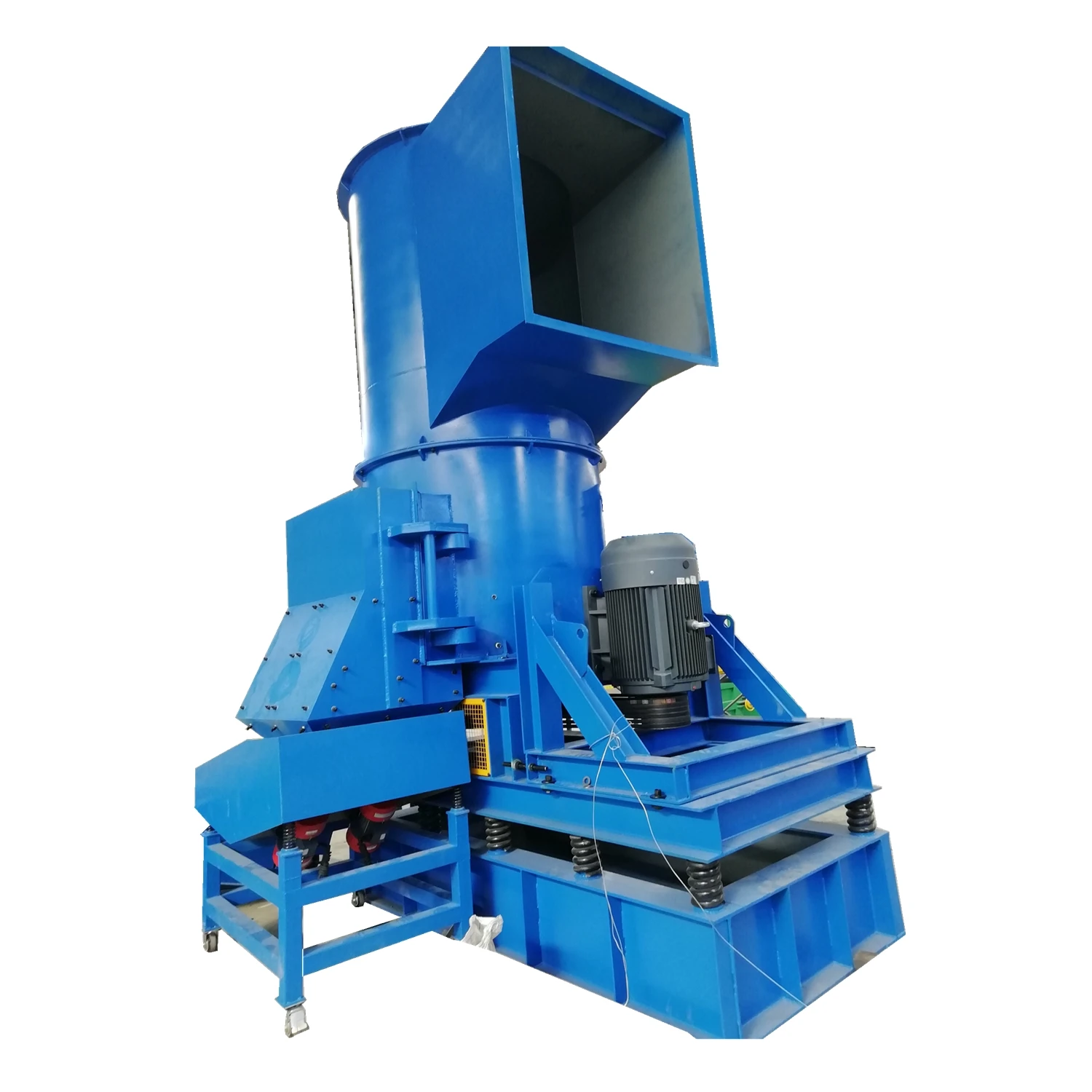

Technological advancements in shredding and sorting machinery also play a pivotal role. Modern shredders featuring improved efficiency and separation capabilities can significantly lower the processing costs and enhance the purity of the scrap output. For businesses looking to maximize profits, investing in high-end technology not only enhances operational efficiency but also boosts the final product's quality, allowing them to command better prices.

shredder scrap prices

Moreover, regulatory policies and environmental considerations have increasingly become significant. Many countries are implementing stringent environmental rules on waste export and recycling, which can affect the availability and cost of scrap materials. Businesses must navigate these regulations with precision and ensure compliance to avoid legal hurdles and potential financial penalties. Developing a robust understanding of these regulatory landscapes is vital for maintaining competitiveness in the global market.

Supply chain logistics also impact shredder scrap pricing. Efficient logistics can reduce transportation costs and ensure timely delivery of materials, making it easier to align with market demands. Scrap yards and recycling facilities that optimize their supply chain operations often see more stable pricing due to enhanced reliability in their supply commitments to buyers.

In conclusion, navigating the complexities of shredder scrap pricing requires a multifaceted approach encompassing quality assessment, market insights, technological adoption, regulatory compliance, and logistics efficiency. By harnessing expert knowledge and adopting a strategic mindset, businesses and stakeholders can not only optimize their operations but also secure advantageous market positions. It's imperative to stay informed, adapt to changing market conditions, and invest in technology and compliance to truly harness the potential of this dynamic industry.