Selecting the right shredder for metal can transform the efficiency and safety of a business. Metal shredders are indispensable for industries that deal with metal scraps, recycling, and waste management. They not only help in reducing the volume of waste but also prepare metal for recycling, ultimately contributing to environmental sustainability. However,

finding a shredder that fits your requirements needs careful consideration. Herein lies the crucial elements to guide your purchase decision, enriched by real-life insights.

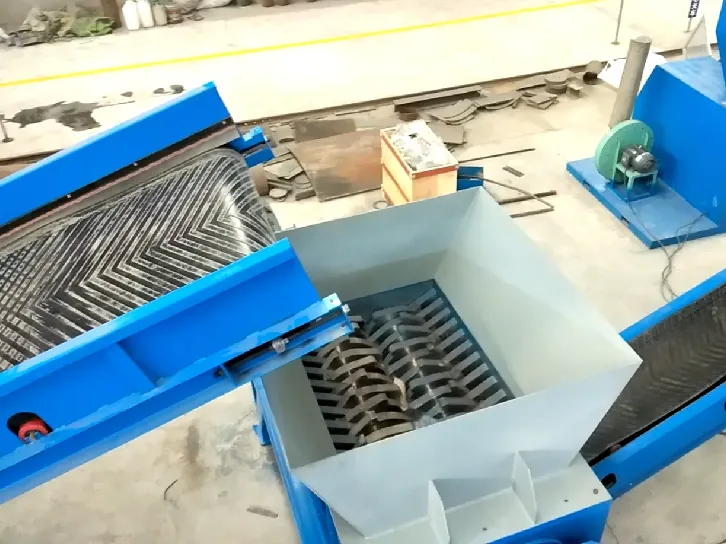

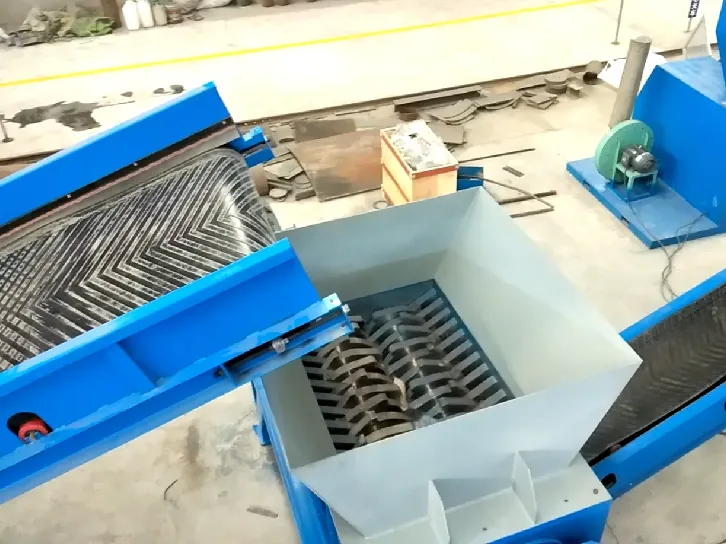

A keen understanding of what each shredder type offers can greatly enhance your selection process. There are multiple designs on the market, each serving distinct needs. The most common include single-shaft shredders, twin-shaft shredders, and granulators. Single-shaft shredders are favored for their ability to handle complex and heavy-duty applications. They excel in grand capacity and efficiency, flawlessly breaking down large metal pieces. Twin-shaft shredders, conversely, are renowned for their high torque and versatile shredding capabilities, ideal for bulky materials that need precise cuts. Granulators, although primarily utilized for plastics, can finely shred thin metal slices – perfect for producing uniform materials ready for recycling.

Immersion in industry specifics reveals why customization matters. Each industrial sector imposes unique challenges on equipment. For example, automotive industries need shredders that can manage substantial quantities of metal frame waste with speed. Conversely, electronic recycling sectors focus on shredders that can separate metals from other components without compromising the integrity of recyclable parts. This sector-specific need for customization heightens the importance of selecting a manufacturer that offers tailor-fit shredding machinery.

In terms of operational expertise, consideration of the machine's noise levels, energy consumption, and maintenance requirements is crucial. High noise levels may impede worker productivity and violate regulatory standards, while energy-efficient shredders can significantly reduce operational costs. Additionally, seamless maintenance ability minimizes downtime, thus ensuring that businesses remain operational and profitable. Experienced operators should check for shredders built with quality materials that can withstand high-pressure conditions, thus ensuring longevity and reliability.

shredder for metal

Addressing the safety and compliance perspective is non-negotiable. Modern shredders incorporate advanced safety features like automated shut-off controls, access restrictions, and emergency stop mechanisms. Compliance with international safety standards such as ISO and CE certifications guarantees that the shredders are built to the highest quality standards, which is a testament to their engineering excellence.

From an authoritative stance, industry leaders often prioritize partnerships with manufacturers who demonstrate environmental consciousness. Metal shredders contribute significantly to the recycling process, and partnering with manufacturers committed to sustainable practices boosts a company's environmental credibility. Ensuring that these shredders incorporate technologies to efficiently separate metal types ensures that recycling processes conform to global ecological standards.

Trust, intrinsically woven through vendor-customer relationships, is paramount in making shredder investments. Opt for manufacturers whose equipment bears certifications from recognized bodies, which not only confirms adherence to stringent standards but also provides assurance of product quality. Customer testimonials and case studies revealing successful adoption of shredders across various industries can further guide decision-making, showcasing real-world efficacy and reliability.

In conclusion, the procurement of a metal shredder demands in-depth understanding and careful contemplation of several factors. Ensuring that the machine aligns with the functional needs and operational safety of your enterprise can revolutionize metal waste management. By weighing industry-specific requirements against the backdrop of expertise, safety standards, environmental considerations, and vendor trustworthiness, you are well-placed to make an informed and strategic choice.