In the dynamic world of industrial machinery, scrap metal shredders stand out as pivotal tools, revolutionizing the recycling landscape. They not only enhance the recycling process but also contribute significantly to environmental conservation by processing large volumes of metal waste into manageable, reusable forms. As industries adapt to greener practices, understanding the price dynamics of scrap metal shredders has become crucial for stakeholders seeking optimal investment returns.

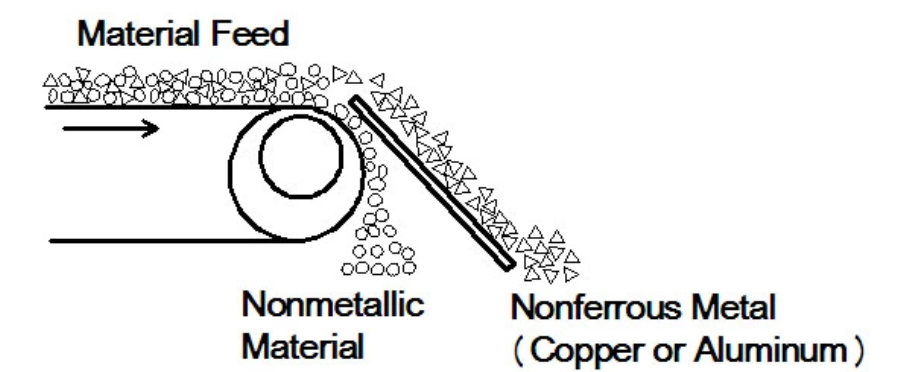

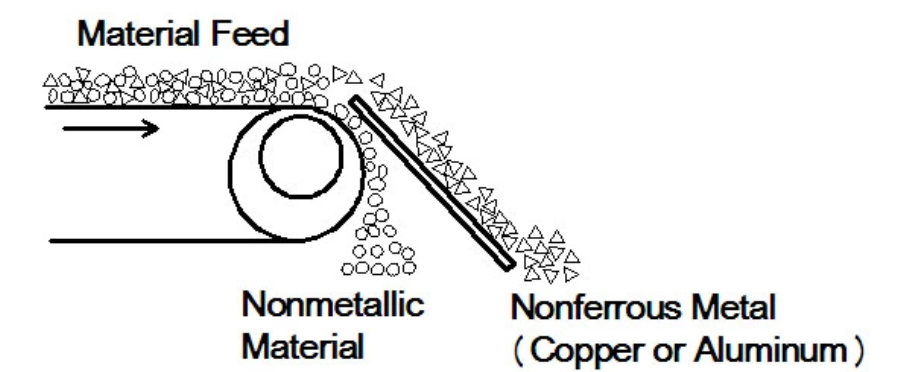

Scrap metal shredders, known for their robust designs, are engineered to handle various metal types, including aluminum, steel, copper, and alloys, by reducing them into smaller pieces. This capability is vital for easing the separation and purification of metals, thus enhancing their recyclability. However, the cost of acquiring these shredders varies widely, shaped by several factors that require careful consideration from potential buyers.

One of the dominant factors influencing the price is the size and capacity of the shredder. Larger machines with higher throughput capabilities naturally command higher prices due to their ability to process more material in less time. For instance, industrial-scale shredders capable of processing up to 20 tons per hour can cost significantly more than medium-sized versions designed for smaller operations. Thus, businesses must assess their specific needs and processing volumes to align their investment accordingly.

Technological advancements in shredding machinery also impact pricing. Modern shredders equipped with smart technologies for enhanced efficiency, energy savings, and predictive maintenance tend to be priced higher than basic models. For example, machines integrated with automated sorting and separation features not only streamline operations but also reduce labor costs, effectively justifying the initial higher investment through long-term savings. Prospective buyers must weigh these technological benefits against their budget constraints to make informed decisions.

Another crucial consideration is the build quality and material composition of the shredder. Machines constructed with superior materials and components, designed for extended durability and minimal maintenance, typically attract premium prices. A shredder with a reinforced frame and high-torque rotors, built to resist wear and tear from heavy-duty shredding, is a wise investment for businesses looking to minimize downtime and maintenance expenses.

scrap metal shredder price

Geographical location and market demand further complicate the pricing landscape for scrap metal shredders. Regions with a burgeoning recycling industry may experience inflated prices due to high demand, accompanied by longer lead times for delivery. Additionally, import tariffs and logistical considerations can affect the final cost for buyers located in areas distant from manufacturing hubs.

Suppliers and manufacturers themselves influence price points through their brand reputation and the level of customer support offered. Established brands with a track record of reliable performance and comprehensive support services might charge a premium, but they often provide added value through warranties, training, and after-sales service. This reliability can be crucial for businesses seeking assurance of consistent operational uptime and quick resolution of any technical issues.

In this competitive marketplace, potential buyers should prioritize due diligence and engage in comprehensive cost-benefit analysis before committing to a purchase. Consulting industry experts and existing users can provide valuable insights into the machine's performance and operating costs. Furthermore, exploring financing options can alleviate the financial burden, making high-end models more accessible to businesses with constrained capital.

Ultimately, the decision to invest in a scrap metal shredder and its associated price should be aligned with a company’s long-term strategic goals. Whether the focus is on maximizing throughput, minimizing operational costs, or enhancing metal recovery rates, understanding the full scope of factors affecting shredder prices ensures a purchase that offers significant returns on investment.

In conclusion, purchasing a scrap metal shredder is a substantial commitment that extends beyond the initial expenditure. By considering factors like size, technology, build quality, geographical implications, and supplier reputation, companies can make strategically sound decisions. A well-chosen shredder not only promises to boost productivity but also reinforces a company’s dedication to sustainable practices, an increasingly important consideration in today's eco-conscious market.