12 月 . 04, 2024 10:04 Back to list

Understanding Scrap Metal Shredder Prices What Drives the Market?

In the ever-evolving world of recycling, scrap metal shredders play a pivotal role in processing a wide range of metallic materials. As industries and consumers alike become more environmentally conscious, the demand for efficient recycling solutions has surged. Consequently, understanding the pricing of scrap metal shredders is crucial for businesses looking to invest in these machines. This article explores the factors that influence scrap metal shredder prices and offers insights into making informed purchasing decisions.

The Basics of Scrap Metal Shredders

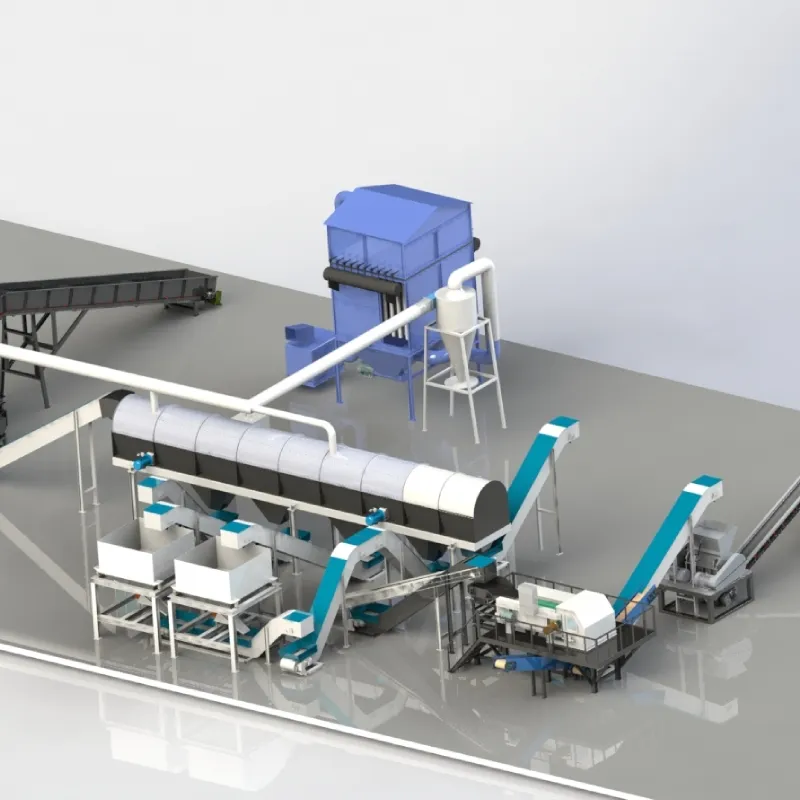

Before delving into pricing, it’s essential to understand the functionality and purpose of scrap metal shredders. These machines are designed to reduce the size of scrap metal into smaller pieces, thus facilitating easy transportation and processing. They are essential in various industries, including automotive, manufacturing, and construction, making them vital for effective recycling operations.

Key Factors Influencing Prices

1. Type of Shredder There are different types of scrap metal shredders available in the market, such as single-shaft, dual-shaft, and hammer mills. Each type has its specific application and efficiency, leading to variations in price. For example, single-shaft shredders are generally less expensive but may not be as efficient for heavy-duty applications compared to dual-shaft or hammer mill shredders, which tend to be pricier.

2. Capacity and Size Pricing is also significantly influenced by the shredding capacity and the size of the machine. Larger machines with a higher throughput capacity usually come with a higher price tag. Businesses must assess their volume of scrap metal and choose a shredder that balances capacity with budget.

3. Brand and Manufacturer The reputation of the manufacturer can greatly affect the price. Established brands often command higher prices due to their track record of durability, support, and technological advancements. Investing in a reputable brand might mean higher upfront costs but can lead to savings in maintenance and downtime in the long run.

4. Technological Features Advanced technological features, such as automated controls, advanced safety features, and energy efficiency, can increase the price of a shredder. However, these features often lead to cost savings over time through lower energy consumption and reduced operational risks. Therefore, businesses should consider the long-term benefits of these features.

5. Material Quality The materials used in the construction of the shredder also play a vital role in determining its price. Heavy-duty steel construction, for instance, will likely cost more than lighter alternatives but will offer greater durability and longevity.

6. Market Conditions The prices of shredders can also fluctuate based on broader market conditions, including the demand for scrap metal, availability of raw materials, and economic factors. During times of high demand for recycled metals, prices for shredders may increase as manufacturers adjust to meet the market's needs.

Average Price Range

On average, the price of scrap metal shredders can range from several thousand to hundreds of thousands of dollars, depending on the factors mentioned above. Smaller, less complex shredders may start around $10,000, whereas large, industrial-grade models can exceed $500,000. Businesses should carefully evaluate their specific needs to avoid over-investing in high-capacity machines that do not match their operational scale.

Conclusion

Investing in a scrap metal shredder is a significant decision that requires a thorough understanding of various influencing factors. By considering the type of shredder, capacity, brand reputation, technological features, material quality, and market conditions, companies can make informed choices that align with their budget and operational goals. Ultimately, the right shredder not only maximizes efficiency and profitability but also contributes to a more sustainable recycling process. As the recycling industry continues to grow, staying informed about the dynamics of shredder pricing will empower businesses to compete successfully in this vital market.

Latest news

Unveiling the Power of Eddy Current Separator

NewsSep.25,2024

Transform Your Home Recyclin:home metal shredder

NewsSep.25,2024

The Future of Waste Management with Recycling Line Picker

NewsSep.25,2024

The Benefits of a Metal Recycling Plant

NewsSep.25,2024

Revolutionize Material Separation with Onwang Technology

NewsSep.25,2024

Innovative Waste Management: Unveiling the MSW Sorting Plant

NewsSep.25,2024