Scrap metal shredder machines are revolutionizing the industry, and their importance is growing as we aim for a more sustainable future. With increased awareness about the environmental impact of waste, businesses and manufacturers are now focusing on recycling and efficient waste management systems. One key player in this realm is the scrap metal shredder machine, an indispensable tool in the process of recycling metal materials.

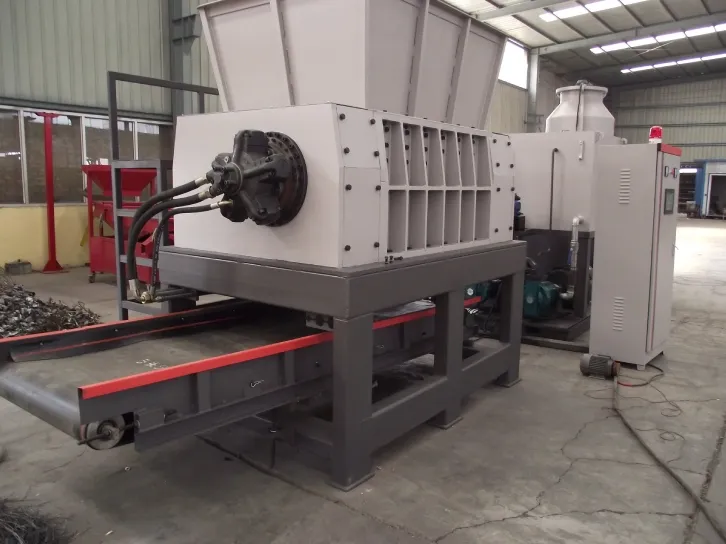

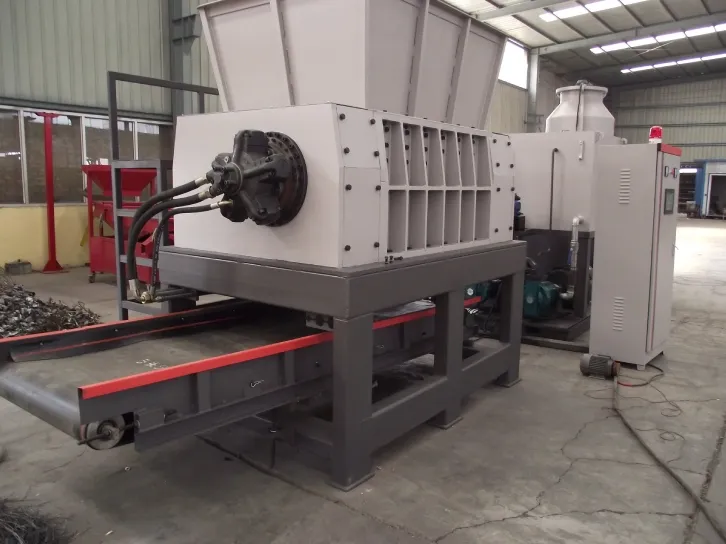

These machines boast advanced technology for reducing large metal pieces into smaller, manageable sizes, which are then transformed into reusable materials. The robust design ensures high efficiency, working tirelessly to make the shredding process smooth and cost-effective. The robust build quality of these shredders is indicative of their specialization in handling a variety of metal types, from aluminum and copper to iron and steel, reinforcing their status as industry workhorses.

Experience counts significantly in this domain. Established manufacturers of scrap metal shredder machines rely on rich histories of expertise. They understand not only the technical aspects of their machines but also the specific needs of different sectors such as automotive, construction, and municipal operations. Select models come equipped with cutting-edge technology aimed at increasing output while reducing energy consumption—a primary focus in today’s eco-conscious industrial practices.

Expertise in designing such machines lies in the innovation incorporated into their cutting teeth and robust motor systems. Precision engineering ensures that these shredders can withstand continuous use in harsh environments without frequent breakdowns. This feature is paramount as consistent operation equates to higher profitability and less downtime—a critical metric for businesses dealing with large volumes of metal.

scrap metal shredder machine

Authority within this industry stems from strict compliance with international safety and quality standards. Recognized manufacturers ensure that their machines are certified, thereby averting potential operational hazards. In addition, authoritative companies provide continuous support and updates, making certain that their clients are equipped with the latest tools and processes. This not only maximizes efficiency but also guarantees adherence to global best practices in waste management and recycling efforts.

Trustworthiness is further cemented by user testimonials and long-term customer relationships. Businesses that depend on these machines vouch for their durability and the straightforward integration into existing recycling workflows. Many industries prioritize vendors with proven track records, as investing in a reliable scrap metal shredder machine can be a significant financial commitment. Assistance in installation and ongoing support assures users that they are backed by a dependable partner in their recycling journey.

In conclusion, scrap metal shredder machines are indispensable in advancing eco-friendly waste management solutions. Their development represents a culmination of experience, expertise, authority, and trust that manufacturers instill in their products. As industries continue to navigate the challenges of environmental responsibility and operational efficiency, these machines will remain at the forefront, facilitating the seamless recycling of metals and contributing to a more sustainable and economically viable future.