Scrap metal crushers are becoming an indispensable tool in recycling processes worldwide, ushering in a new era of sustainable metal management. These powerful machines are revolutionizing the way industries handle metal waste, offering economic and environmental benefits that underscore their growing significance.

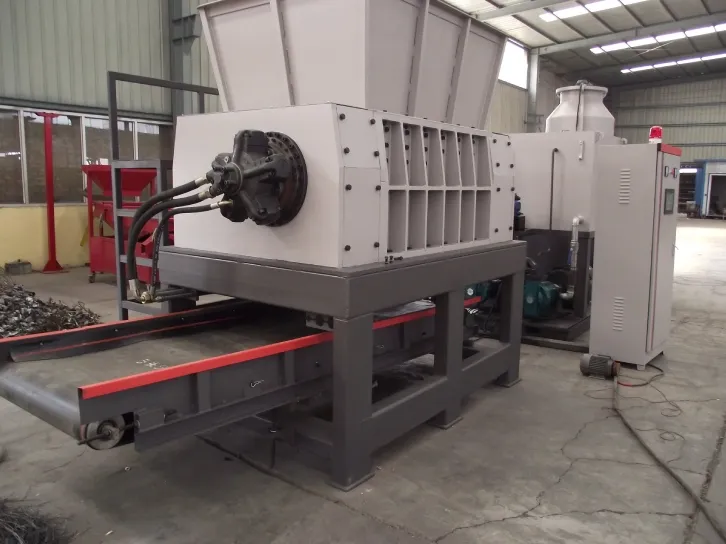

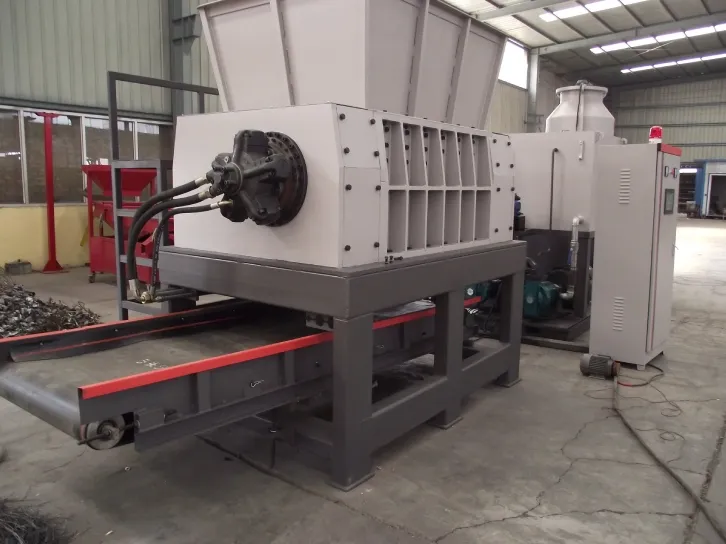

Scrap metal crushers are designed to condense and convert metal waste into reusable materials. They are utilized by industries ranging from automotive to construction, making them critical in the modern industrial landscape. These crushers work by using a succession of heavy-duty blades and powerful motors to break down metal into smaller, manageable pieces. This process not only aids in recycling efforts but also helps in efficient storage and transportation of scrap metal.

The experience of using a scrap metal crusher is transformative for businesses focused on efficiency and sustainability. Operators quickly realize the cost savings involved in turning waste into profit. Through first-hand experience, many have observed substantial reductions in waste management costs and space optimization within their facilities. Additionally, by reducing metal waste volumes, companies can comply more easily with local and international waste disposal regulations, thereby avoiding fines and boosting their reputational standing.

Expertise in managing scrap metal crushers can result in optimized operational workflows. Skilled operators or businesses specializing in metal recycling utilize these machines to their fullest potential, harnessing nuances of various models, sizes, and brands to match specific industrial needs. This expertise ensures maximum recovery of valuable metals such as aluminum, copper, and steel, which can be melted down and reused — minimizing the need for virgin raw material extraction.

scrap metal crusher

The authoritativeness of scrap metal crushers is evident through their adoption by leading recycling and waste management companies. These businesses often report a marked improvement in operational efficiency and sustainability metrics. Research studies sponsored by prominent environmental organizations corroborate these findings, showcasing how efficient metal processing significantly reduces carbon emissions associated with metal production.

Trustworthiness in scrap metal crushers is enhanced by ongoing advancements in technology, ensuring the reliability and safety of these machines. The latest models boast advanced control systems, ensuring precise operations and minimizing machine downtown due to maintenance issues. Manufacturers who commit to regular updates and provide comprehensive user training further bolster trust among users.

In sum, the advantages of scrap metal crushers extend far beyond mere waste management. They embody the principles of the circular economy, demonstrating how technology and innovation can drive forward both business success and environmental preservation. By converting metal waste into a valuable resource, these crushers help industries meet the demands of a world increasingly focused on sustainability. As the trend towards responsible resource management gains traction, scrap metal crushers will undoubtedly be at the forefront of this movement, enabling companies to achieve their economic and ecological goals with precision and reliability. Given their multitude of benefits, it's no surprise that the demand for these machines continues to rise, earning them a deserved place in the pantheon of essential industrial equipment.