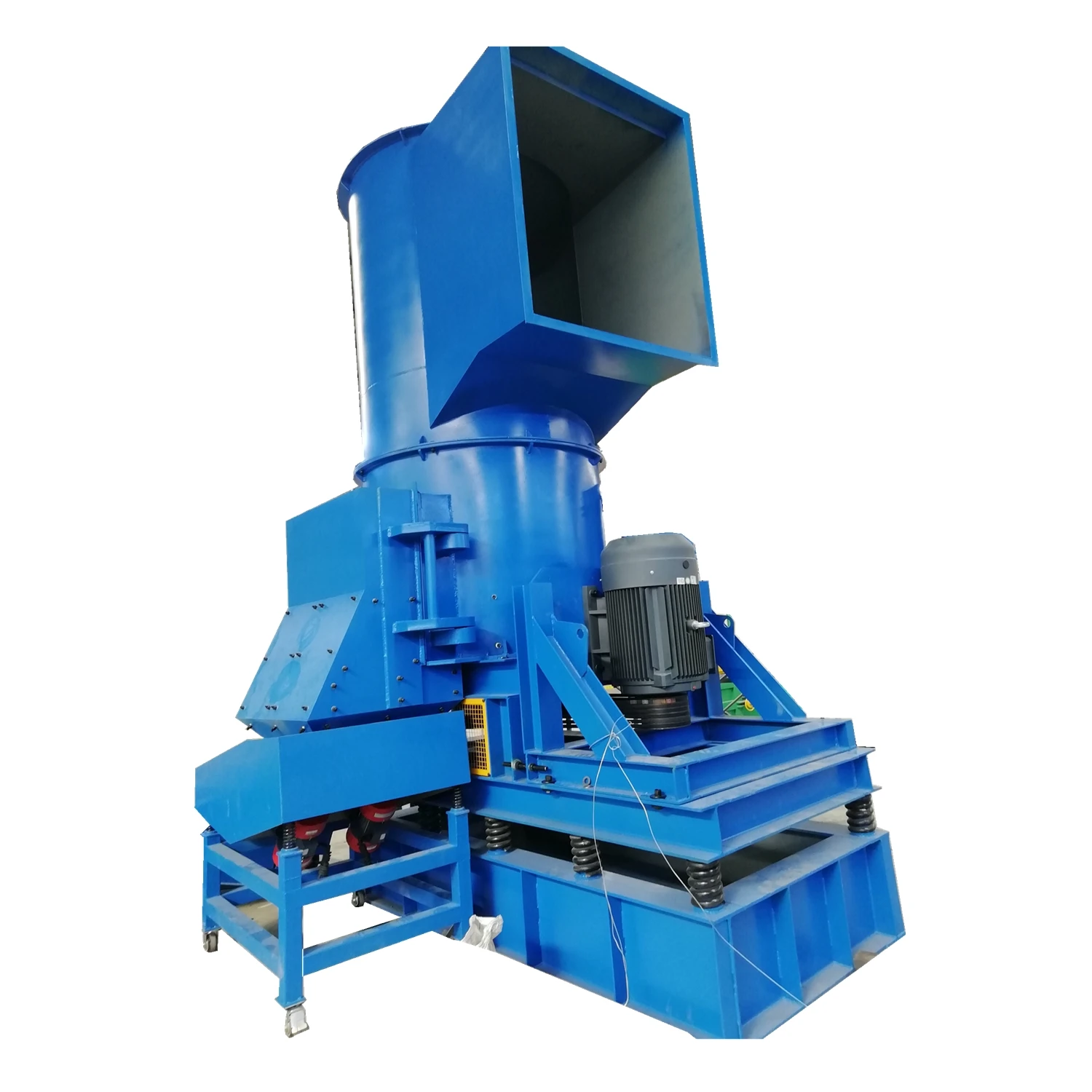

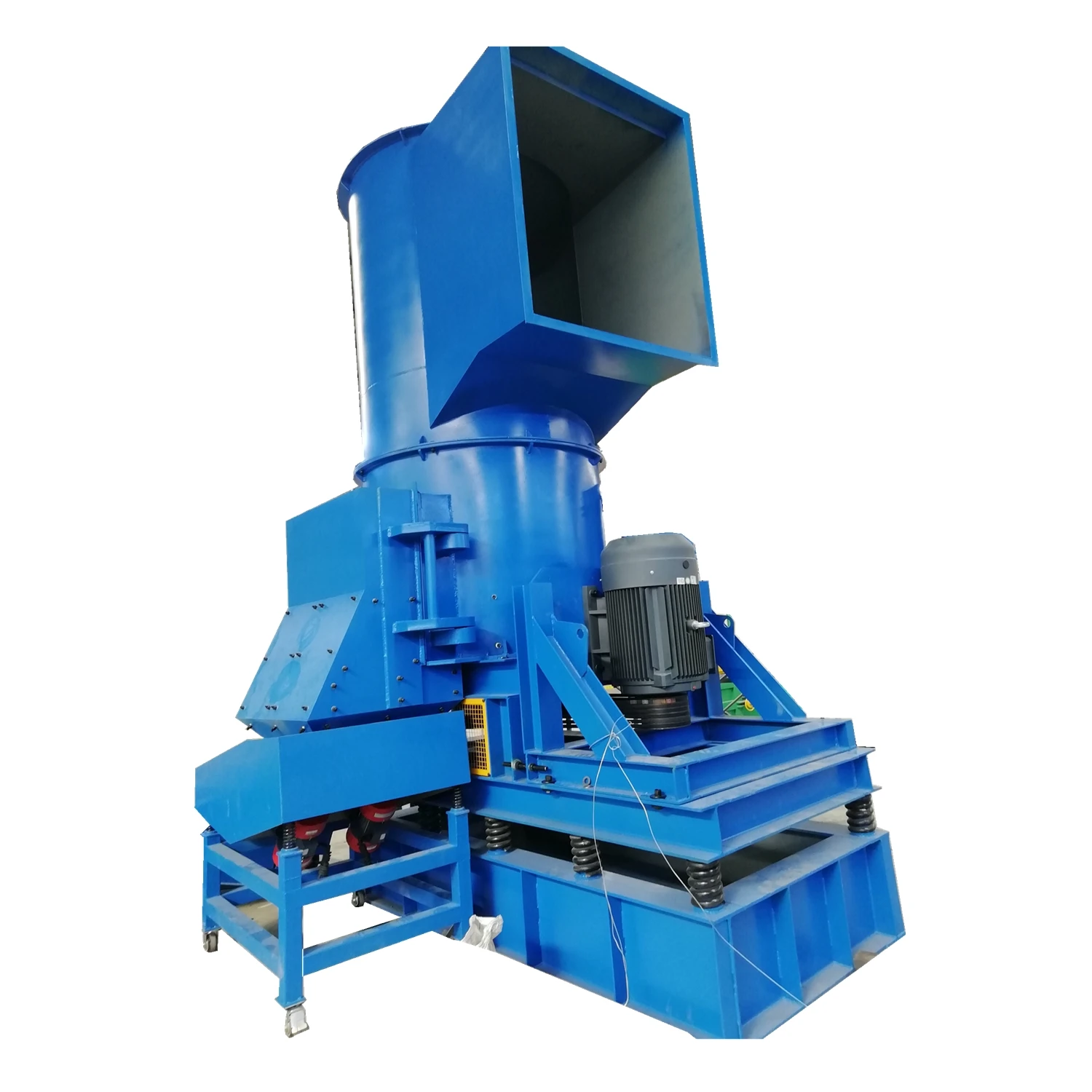

Navigating the complexities of scrap iron shredders requires a nuanced understanding of industrial machinery and recycling processes. As a cornerstone in metal recycling, scrap iron shredders play an instrumental role in transforming bulky metal waste into valuable raw materials. Their impact on sustainability cannot be overstated, as they enable the efficient processing of metal scraps into reusable forms, significantly reducing the need for mining virgin materials.

The scrap iron shredder is an engineering marvel, designed with precision to handle various types of metal waste. These shredders are favored for their ability to deconstruct large volumes of metal quickly and efficiently. In an industry where time and efficiency equate to cost savings and productivity gains, the performance metrics of these machines are critical. They are typically engineered with robust, wear-resistant materials to endure the harsh conditions of metal shredding.

A deep dive into the mechanics reveals that scrap iron shredders operate on a rotor system fitted with heavy-duty blades.

This rotor spins at high speeds, tearing the scrap into smaller and manageable pieces. The result is a pile of metal that's easier to handle, transport, and melt down into reusable forms. This systematic breakdown of materials not only enhances recycling processes but also supports environmental conservation by minimizing waste.

Operational expertise is crucial when managing a scrap iron shredder. Operators must be well-versed in machine maintenance and safety protocols to ensure optimal performance and longevity. Training programs focusing on the technical aspects of the shredder—such as hydraulic power units, frame integrity, and blade maintenance—are essential for maintaining peak efficiency and safety standards. Moreover, understanding the intricacies of different shredding technologies, such as single, double, or quad shaft systems, can influence the choice of machine depending on the specific needs of a recycling operation.

scrap iron shredder

From an expert's standpoint, the selection of a scrap iron shredder should be guided by the specific requirements of your recycling facility. Considerations should include the scale of operations, the variety of scrap types processed, and the desired output size. Advanced models equipped with smart technology offer monitoring systems for real-time data analysis, enhancing both productivity and preventative maintenance capabilities.

Trustworthiness in scrap iron shredders often centers around manufacturer reputation and the support services they provide. A reliable manufacturer typically offers comprehensive post-sale services, including professional maintenance, rapid spare part replacements, and technical support. These services are indispensable for minimizing downtime and ensuring the machine operates at its full potential.

When evaluating the authoritativeness of information surrounding scrap iron shredders, it's vital to rely on resources backed by industry certifications and case studies. Peer-reviewed articles, industry reports, and documentation from recognized recycling associations serve as invaluable sources of credible and technically sound information. Networking with industry professionals and attending trade shows can also provide insight into the latest advancements in shredder technology and recycling best practices.

In conclusion, scrap iron shredders are pivotal in the recycling industry for their efficiency and role in sustainability efforts. A profound understanding of their operation, maintenance, and the market landscape is essential for anyone aiming to leverage these machines effectively. Ensuring you stay informed through expert sources and employing best practices in operation and maintenance will facilitate not only robust performance but also contribute to an increasingly sustainable future.