The evolution of scrap iron shredders has significantly transformed the metal recycling industry, offering unparalleled efficiency and sustainability. As the global demand for recycled metal skyrockets, scrap iron shredders have emerged as indispensable tools, enabling businesses to optimize their recycling processes. This article will delve into the multifaceted world of scrap iron shredders, examining their operational benefits, technological advancements, and the impact they have on both the economy and the environment.

Scrap iron shredders, often regarded as the backbone of metal recycling facilities, are engineered to process complex metal scraps into manageable sizes.

By reducing bulky iron scraps into smaller, uniform pieces, shredders facilitate easier handling, transportation, and further processing. This not only maximizes efficiency but also enhances the profitability of recycling operations. With the advancement of technology, modern shredders are equipped with automated systems and sensors that ensure precision cutting while minimizing energy consumption. This technological leap enhances the operational capability of the shredders, making them suitable for high-throughput environments.

One of the foremost benefits of employing scrap iron shredders is the considerable cost reduction in recycling operations. By streamlining the process of metal fragmentation, businesses can decrease the need for manual labor and reduce transportation costs. Shredded iron occupies less space, thereby allowing more material to be transported in a single trip. This directly translates into lower fuel expenditure and labor hours, significantly cutting down the overall operational costs.

Moreover, the use of scrap iron shredders contributes to sustainable practices by promoting the efficient utilization of resources. With environmental concerns taking center stage, reducing carbon footprints has become a priority for industries worldwide. Shredding minimizes waste and optimizes the recycling process, thereby decreasing the reliance on natural resources for new metal production. By recycling metals more efficiently, companies can lower their environmental impact and contribute to a circular economy. This sustainable approach not only supports long-term profitability but also enhances a company's brand reputation as a leader in eco-friendly practices.

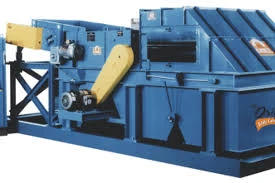

scrap iron shredder

Analyzing the technological aspects, modern scrap iron shredders are outfitted with cutting-edge features like adjustable speed controls, dust suppression systems, and noise reduction technology. These enhancements ensure that the shredders operate smoothly under various conditions and comply with stringent environmental regulations. Integrated safety features, such as emergency stop mechanisms and overload protection, make these machines not only efficient but also safe to operate. The incorporation of the Internet of Things (IoT) into shredder technology offers further advantages by enabling real-time monitoring and maintenance scheduling, thus minimizing downtime and maximizing productivity.

In addition to operational benefits, the broad market for shredded scrap iron bolsters its economic significance. Processed scrap iron is in high demand across several industries, including construction, automotive, and manufacturing. By increasing the supply of high-quality recycled metal, shredders play a pivotal role in stabilizing metal prices and ensuring a steady flow of materials for industrial use. This economic contribution underscores the shredder's importance as a keystone in the sustainability framework of modern manufacturing.

To successfully implement scrap iron shredders into recycling operations, businesses must navigate several considerations. Choosing the appropriate shredder involves an assessment of material type, volume, and desired output size. Furthermore, companies must consider the space available, power requirements, and potential integration with existing recycling systems. Proper training for operators and regular maintenance checks are essential to ensure the longevity and reliability of these machines. Collaborating with experienced manufacturers who can provide comprehensive support and customization options can significantly streamline the implementation process.

In conclusion, scrap iron shredders represent a vital innovation in the realm of metal recycling. By enhancing operational efficiency, reducing costs, and supporting sustainable practices, they embody the intersection of technology and environmental stewardship. As industries globally embrace recycling as a cornerstone of sustainable development, the role of scrap iron shredders will only become more critical. Businesses that invest in this technology today are not only positioning themselves as leaders in sustainability but are also ensuring their competitiveness in an increasingly eco-conscious market.