Scrap crusher machines are revolutionary tools in the waste management and recycling industries, transforming the way materials are processed, recycled, and reused. Their integral role in enhancing operational efficiency and sustainability is evident across various sectors, from automotive to construction. Let's delve into why these machines are pivotal, how they work, and what potential buyers should consider when investing in one.

At their core, scrap crusher machines are designed to reduce large metal materials into more manageable sizes, making them easier to handle, transport, and recycle. These powerful tools can crush everything from aluminum and steel to copper and other alloys, ensuring that nothing goes to waste. The ability to process large volumes of metal scrap quickly and efficiently gives businesses a significant edge, reducing labor costs and downtime while increasing throughput.

When discussing the effectiveness and efficiency of scrap crusher machines, it’s important to emphasize the design considerations that make them stand out. For instance, advanced technology in modern crushers includes automated settings, which allow operators to control the size of the output material accurately. These settings ensure that the processed scrap meets specific industry standards and recycling requirements, enhancing the material's value for resale or repurposing.

Durability and reliability are key attributes of high-quality scrap crusher machines. Built with robust materials and designed to withstand intense pressure, these machines offer long-lasting performance even under the most demanding conditions. Many machines are equipped with wear-resistant features, such as replaceable lining plates, that minimize maintenance needs and extend the machine's lifespan.

From an expertise point of view, a significant advantage of using a scrap crusher machine is the environmental impact reduction. By processing metal scrap efficiently, these machines reduce the need for new raw materials, thereby conserving natural resources and reducing the carbon footprint associated with metal production. Furthermore, well-crushed scrap is easier to separate into pure grade materials, which ensures higher recycling rates and better environmental outcomes.

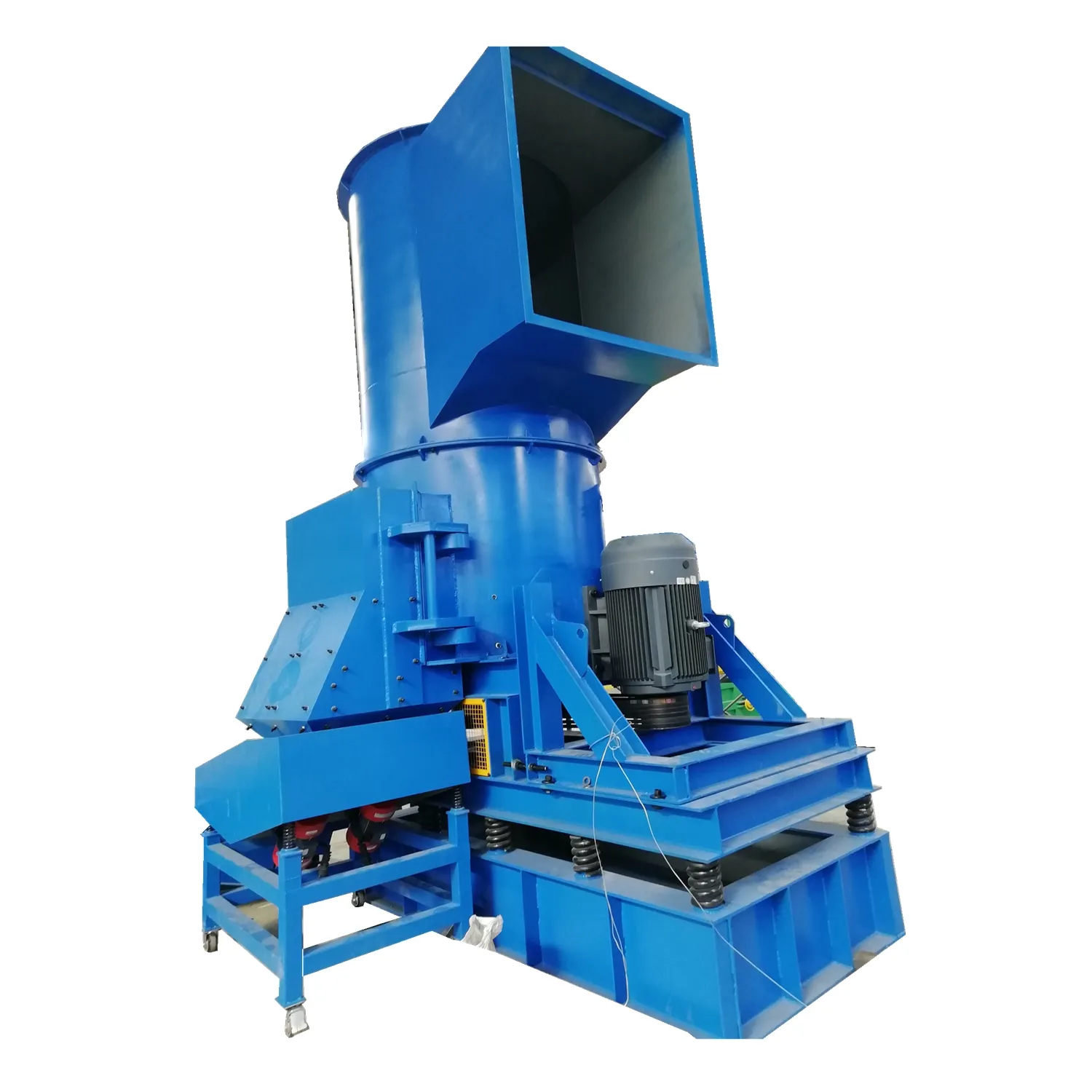

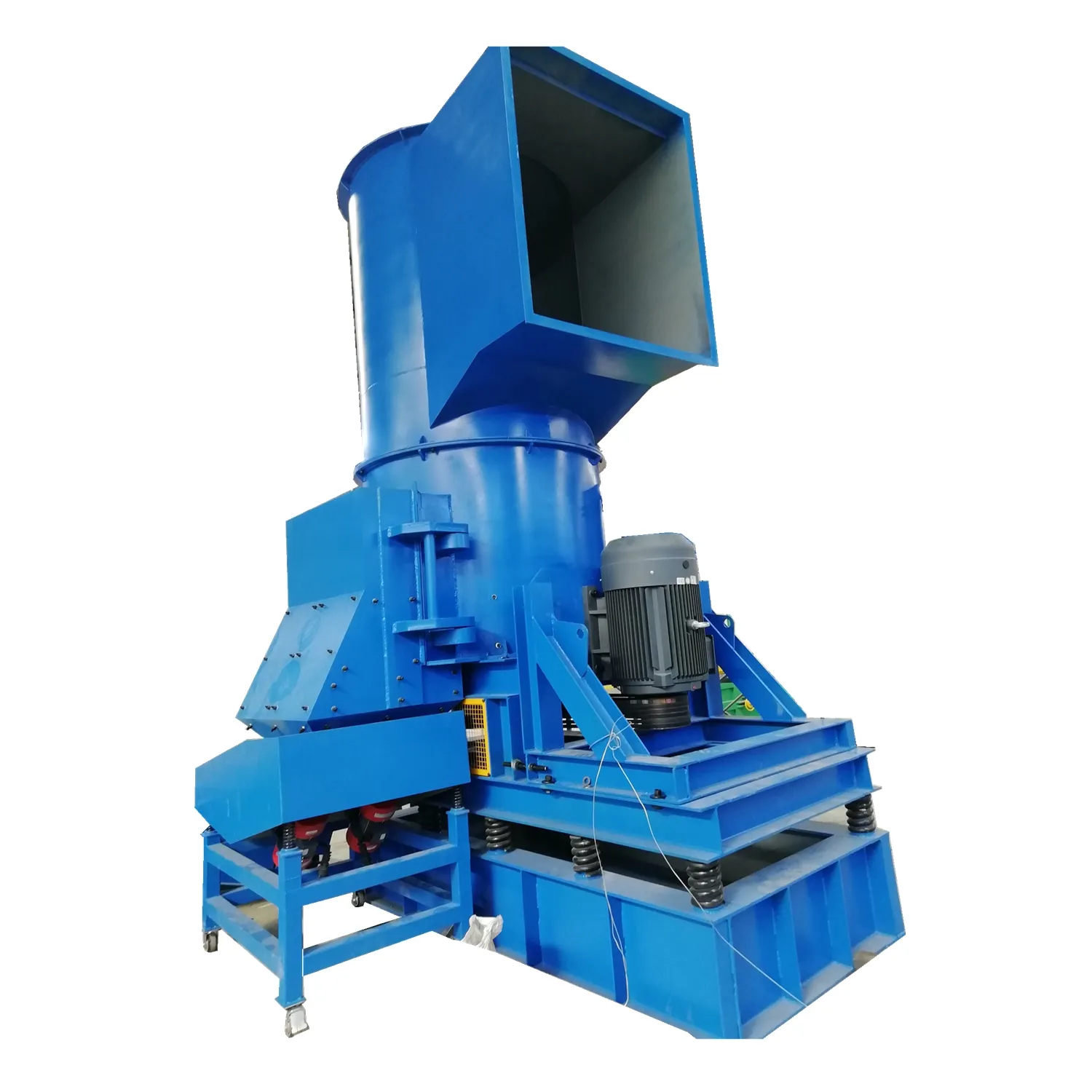

scrap crusher machine

For businesses looking to incorporate a scrap crusher machine into their operations, understanding the options available is crucial. Machines vary widely in terms of size, capacity, and the types of materials they can process. Smaller models might suffice for businesses dealing with low to moderate volumes of scrap, while larger industrial-scale crushers are necessary for handling high-capacity needs. Consulting with experienced professionals can guide enterprises in selecting the machine that best aligns with their operational goals and budget.

Authoritativeness in the field of scrap crushers is also about considering future trends and technology advancements. The integration of smart technologies, such as IoT sensors and real-time monitoring, offers promising advancements in predictive maintenance and operational efficiency. These technologies can alert operators to potential issues before they cause significant downtime, thus safeguarding the investment and enhancing machine productivity.

Moreover, the trustworthiness of a manufacturer can significantly influence a product's performance and value over time. Choosing a reputable brand known for outstanding customer service, comprehensive warranties, and a strong track record in the recycling industry can offer peace of mind and ensure a positive return on investment. It’s advisable to seek machines that have been rigorously tested and certified by recognized industry bodies, guaranteeing adherence to the latest safety and efficiency standards.

In conclusion, scrap crusher machines represent a blend of innovation, efficiency, and sustainability, indispensable for modern recycling and waste management operations. Their ability to process and repurpose metal scraps not only contributes to significant cost savings and environmental benefits but also aligns with global trends towards more sustainable industrial practices. As technology evolves, staying informed about the latest advancements and maintaining a focus on quality and reliability is essential for any business committed to optimizing its scrap processing capabilities.