In the ever-evolving world of metal recycling and processing, metal shreds play a pivotal role. These finely processed metal fragments are not just a byproduct of industrial activities but a valuable commodity with manifold applications. Throughout this in-depth exploration of metal shreds, we will delve into their production, uses, and significance in the contemporary industrial ecosystem.

Metal shredding is a sophisticated process that involves breaking down large pieces of scrap metal into smaller, manageable parts known as shreds. This transformation is achieved through the use of industrial shredders equipped with sharp, high-speed rotating blades. These powerful machines can handle a diverse range of metal types, from aluminum and steel to copper and beyond, making them indispensable in scrap yards and recycling centers across the globe.

The resurgence in demand for sustainable practices has intensified the importance of metal shreds. Recycling metal shreds is a crucial step towards diminishing the environmental footprint of industrial operations. By recycling, industries can significantly reduce the need for virgin materials, conserve energy, and mitigate carbon emissions. A leading example of this is the aluminum industry, where recycling metal shreds saves up to 95% of the energy required to produce new aluminum from raw ore.

Metal shreds are not only central to recycling initiatives but also serve as raw materials for various manufacturing processes.

In the steel industry, shredded scrap is a vital input in electric arc furnaces. They melt the scrap to form new steel, a process that is markedly more energy-efficient than traditional steel-making methods. The high density and consistent size of metal shreds make them ideal for uniform melting, ensuring high-quality end products.

Beyond steel manufacturing, metal shreds serve a critical function in the production of automotive components. Vehicle manufacturers utilize these shreds to craft lightweight, durable parts, contributing to the production of energy-efficient vehicles. This practice not only leverages the strength-to-weight ratio of metals like aluminum and magnesium but also aligns with global trends towards reducing vehicular emissions.

metal shreds

The robust recycling and reusability of metal shreds underscore their economic significance. Companies that engage in the systematic collection and processing of metal shreds benefit from a cost-effective source of high-grade metal without the volatile pricing associated with raw material markets. As such, they can maintain competitive edge while adhering to global sustainability standards.

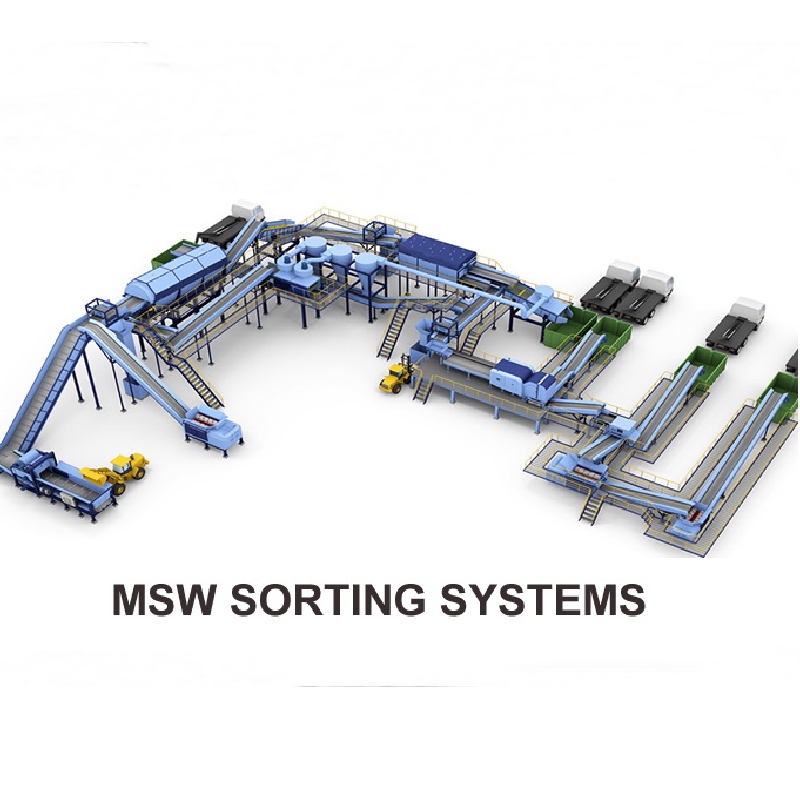

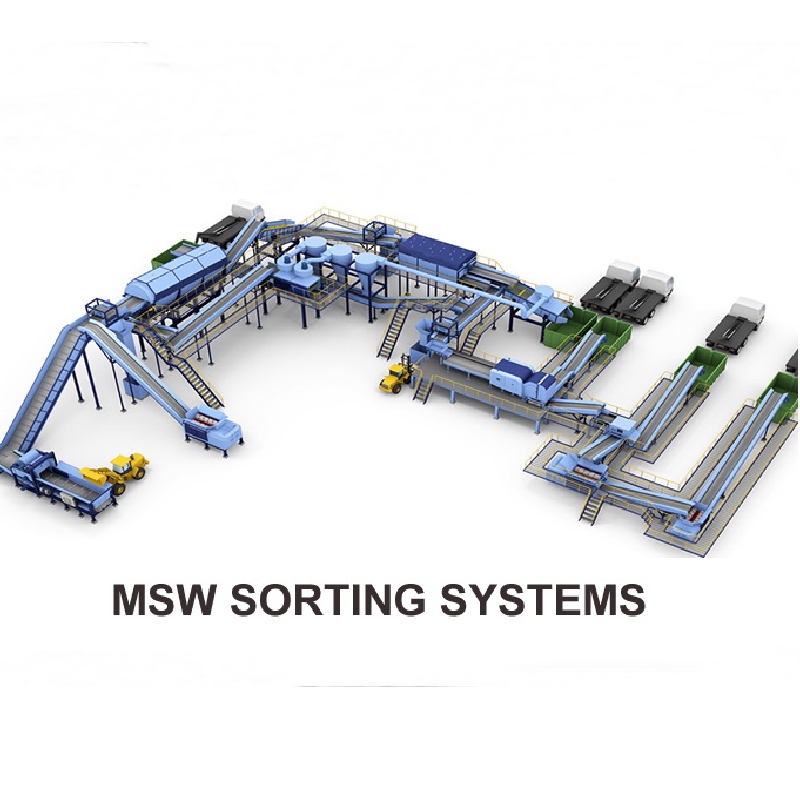

In recent years, innovation in the metal shredding industry has further enhanced the utility and efficiency of the process. State-of-the-art shredders now come equipped with smart technology capable of sorting different metals automatically. This advancement ensures purer batches of metal shreds, thereby elevating their market value. Furthermore, the integration of AI-driven analytics enables precise monitoring and optimization of the shredding process, maximizing operational efficiency.

Trustworthiness and reliability are key factors that businesses must consider when sourcing metal shreds. Partnering with certified and reputable metal recycling companies ensures compliance with environmental regulations and ethical standards. These partnerships guarantee not only the quality of the metal shreds but also accountability throughout the supply chain.

As the demand for sustainable industrial practices grows, the role of metal shreds in the global economy is expanding. Companies are increasingly turning to business models that emphasize circular economy principles, where metal shreds are a cornerstone. This shift promises to deliver both environmental benefits and economic opportunities, driving innovation across industries.

In conclusion, metal shreds are far more than remnants of industrial processes; they are a vital resource driving sustainability and efficiency in modern manufacturing. Their application spans across industries—from steel and automotive to consumer goods manufacturing—highlighting their integral role in a circular economy. Companies that embrace metal shreds not only enhance their eco-friendly credentials but also position themselves at the forefront of an evolving market landscape, capitalizing on the dual benefits of cost-effectiveness and environmental stewardship.