Metal shreds, or metal scrap, are gaining significant attention in various industries for their versatility and economic value. Their utilization spans across multiple sectors, including construction, manufacturing, and recycling, which propels their demand globally. Understanding the dynamics and intricacies of metal shreds is essential for businesses and consumers aiming to leverage this resource effectively.

Experience with metal shreds reveals their intrinsic value, especially for recycling industries. Metal shredding involves converting bulky scrap metal into smaller, manageable pieces, facilitating easier processing and transportation. It enhances metal recycling efficiency, making it a crucial step for eco-conscious companies striving to promote sustainability. Metal shreds from obsolete machinery and vehicles, for instance, can be repurposed, reducing the need for new materials and supporting a circular economy.

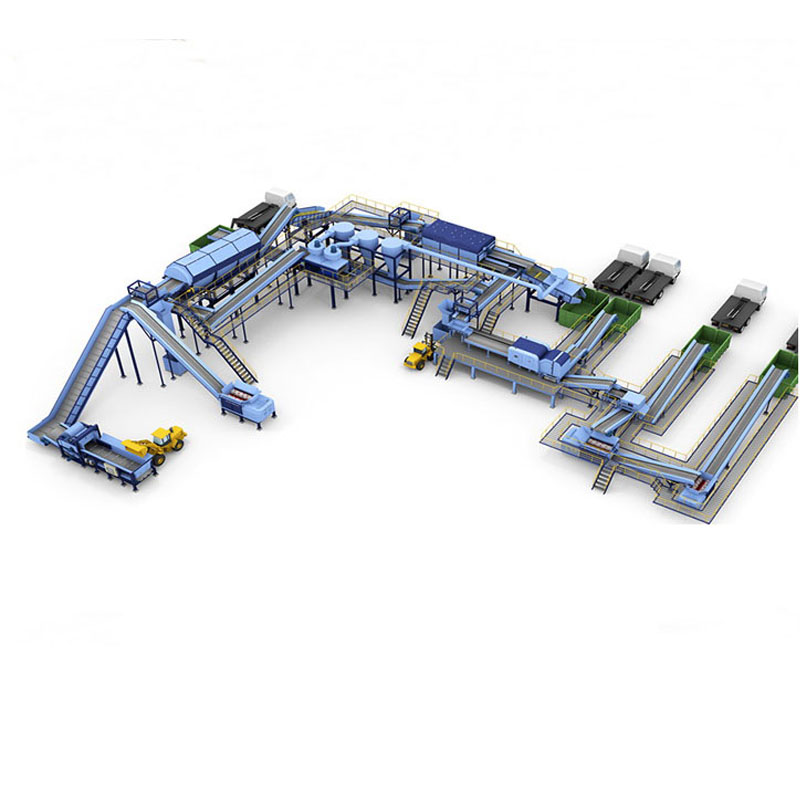

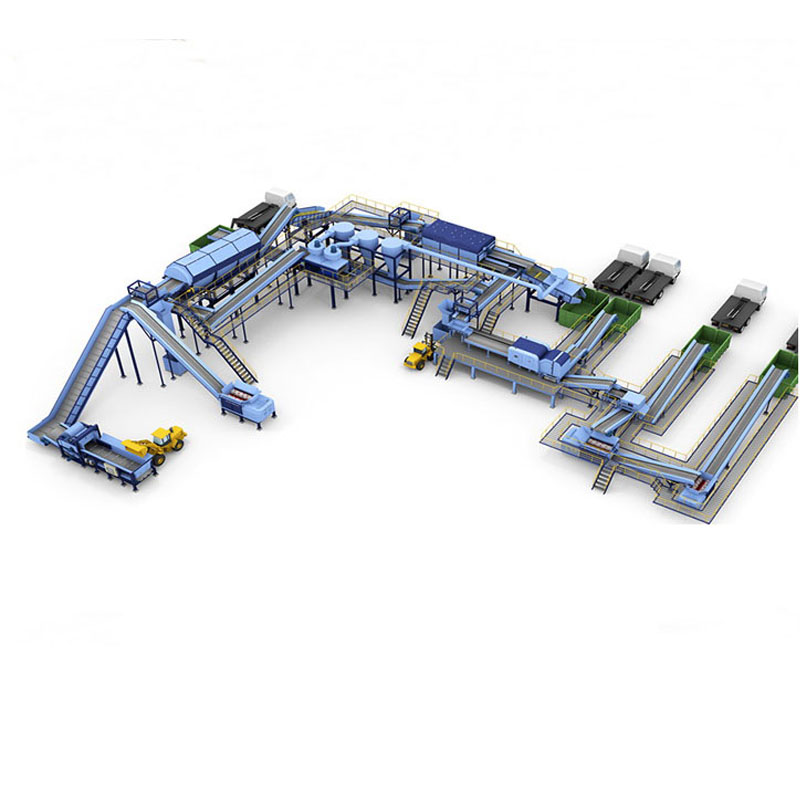

Expertise in handling metal shreds requires knowledge of the right machinery and techniques involved in the shredding process. Industrial shredders used in this process can vary based on capacity, material compatibility, and specific features for metals like aluminum, copper, and steel. Operators skilled in the nuances of different metals ensure the shredders are used optimally, minimizing equipment wear and tear, and maximizing throughput. The technical know-how to distinguish between ferrous and non-ferrous metal shredding is vital, as each type demands different processing protocols.

Authoritativeness in the use of metal shreds is demonstrated by leading industry players setting benchmarks in safety and quality. Companies with certifications in waste management and recycling manifest their commitment to adhering to industry standards.

These certifications validate the reliability of the processes employed for shredding and recycling. Furthermore, partnership with regulatory bodies ensures compliance with environmental guidelines, reinforcing the company’s standing as a trustworthy entity in the metal recycling sphere.

metal shreds

Trustworthiness in the metal shreds industry hinges on transparent operations and responsible sourcing. Businesses involved in metal shredding are expected to maintain integrity in their sourcing practices by avoiding conflict zones and engaging in ethical transactions. Ensuring the traceability of metal scrap from source to end-product guarantees clients about the legitimacy of the raw materials used. Moreover, building a robust relationship with customers through open communication about product lifecycle, potential applications, and environmental impacts of metal shreds fosters a sense of trust and reliability.

From a product perspective, metal shreds offer a sustainable alternative to fresh metal production. They are critical in creating metal alloys, serving as a cost-effective substitute without compromising quality. This positions metal shreds as essential materials in automotive manufacturing where lightweight, durable materials are preferred. In construction, metal shreds are integral in producing reinforcement bars due to their strength-enhancing properties. The unique characteristics of metal shreds, such as corrosion resistance and excellent thermal conductivity, further underscore their importance across various applications.

Moreover, the role of technological advancements cannot be overstated in optimizing the utility of metal shreds. Innovations in shredding technology have led to improved precision and efficiency, resulting in the production of metal shreds of uniform size and shape, which are desirable for specific industrial applications. Integration of AI and machine learning in shredding systems can further enhance process control, enabling real-time monitoring and predictive maintenance of equipment.

In conclusion, the strategic use of metal shreds is imperative for industries aiming to enhance sustainability practices and reduce operational costs. A comprehensive understanding of its benefits, backed by expertise and authoritative operations, can unlock their full potential. Trustworthy sourcing and innovative processing assure quality and compliance, bolstering industry reliability. As industries continue to prioritize environmental responsibility, metal shreds will undoubtedly emerge as a pivotal element in the future of manufacturing and recycling.