Metal recycling has emerged as a cornerstone in sustainable resource management and environmental conservation. Among the various technologies that facilitate this process, the metal recycling shredder stands out as a crucial component due to its ability to efficiently process and repurpose metal waste. The utilization of shredders not only optimizes the recycling process but also significantly contributes to energy conservation and reduction in greenhouse gas emissions.

A metal recycling shredder is engineered to break down large and cumbersome metal scrap into smaller, manageable pieces. This reduction in size is an essential factor that enhances the efficiency of subsequent recycling processes, such as smelting. A well-designed shredder minimizes energy consumption and maximizes throughput, ensuring that the metal recycling facilities can operate economically and sustainably.

From an experiential perspective, integrating a metal recycling shredder into recycling operations has proven transformative. Operators report increased throughput and reduced operational downtime, thanks to the robust build and advanced technology underlying modern shredders. For instance, variable speed drives and intelligent sensors have been incorporated to adjust shredding forces dynamically, addressing different grades and compositions of metal scrap. This reduces wear and tear on machinery, extending their operational life and reducing maintenance costs over time.

Expert insight into the metal recycling industry reveals that shredders play a pivotal role in the circular economy. By transforming end-of-life metal products into reusable materials, these machines break the dependency on virgin metal resources, preserving the environment. The efficiency and effectiveness of shredders are largely dependent on the blade design and the motor power, which are tailored to handle a variety of metals, including aluminum, steel, and copper. Industry experts stress the importance of customizing shredder components to align with specific metallurgical properties to optimize the recycling process.

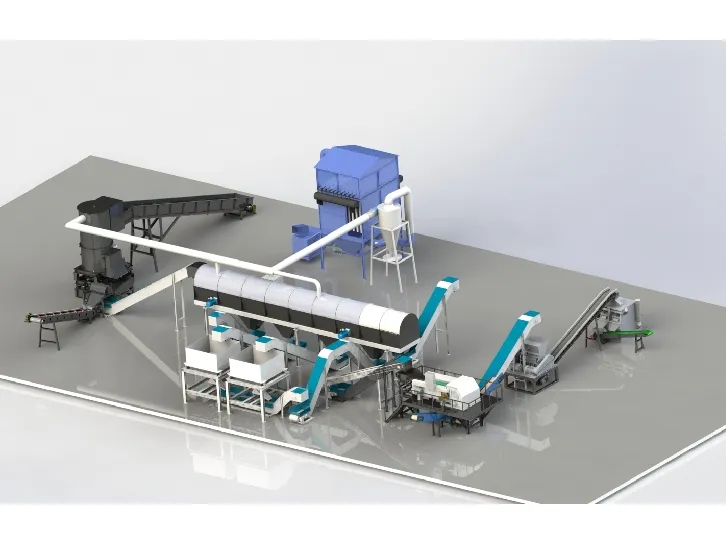

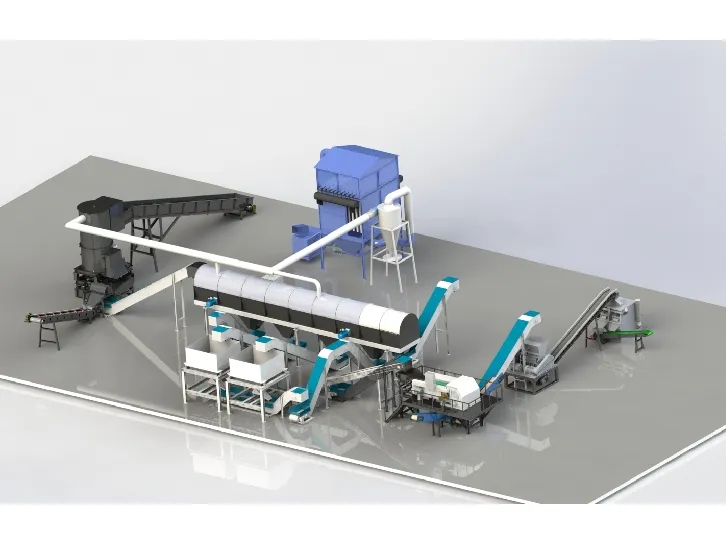

metal recycling shredder

Authoritatively, the global push towards decarbonization has highlighted the importance of metal recycling. Institutions like the International Recycling Bureau and the Institute of Scrap Recycling Industries underscore the environmental and economic benefits that shredders provide. Through regular conferences and publications, these authoritative bodies disseminate knowledge and innovations concerning shredder technology, advocating for widespread adoption across recycling plants worldwide.

Trustworthiness is paramount in selecting and operating a metal recycling shredder. A responsible shredder manufacturer will prioritize not only the performance but also the safety and environmental compliance of their machines. The implementation of dust suppression systems and noise reduction technologies is indicative of a commitment to maintaining a safe working environment. Furthermore, reliable manufacturers provide transparent service agreements and responsive technical support, ensuring that their shredders operate seamlessly and sustainably.

Those in the market for metal recycling shredders should consider several factors before making an investment. Assess the material throughput requirements and select a model that balances performance and energy consumption. Consider the breadth of metals handled; a versatile shredder capable of processing multiple metal types is often more advantageous. Reviewing customer testimonials, case studies, and independent reviews can provide additional insights into the reliability and efficiency of specific shredder models.

In conclusion, investing in a metal recycling shredder is a strategic move towards efficient material recovery and environmental stewardship. The continuous advancements in shredder technology promise greater efficacy and sustainability in metal recycling efforts. Institutions and businesses that have incorporated shredders into their operations consistently report increased efficiency, reduced costs, and a significant positive impact on their environmental footprint. As the world progresses towards a more sustainable future, metal recycling shredders will undoubtedly play an integral role in material recovery initiatives.