A metal crusher machine is indispensable for any operation that involves recycling or processing metal materials. As a cornerstone of metal waste management, these machines are essential in both industrial applications and smaller recycling efforts. With a focus on the core attributes of experience, expertise, authoritativeness, and trustworthiness, this article aims to provide an in-depth understanding of metal crusher machines.

Understanding the Metal Crusher Machine

A metal crusher machine is designed to crush and pulverize metal objects into more manageable pieces. It caters to various materials, including steel, aluminum, copper, and other alloys. The machines come in different sizes and capacities, tailored to meet the demands of various industries such as automotive, construction, and metal fabrication.

Experience with Metal Crusher Machines

Having hands-on experience with metal crusher machines is crucial for optimizing their operation. Operators should be familiar with machine calibration, the intricacies of feeding different types of metal materials, and the specific settings required for diverse outputs. Ensuring regular maintenance and understanding machine diagnostics contribute to prolonged operational lifespan and efficiency. An experienced operator is adept at identifying wear and tear on critical components such as hammers, liners, and bearings, preventing costly downtime and repairs.

Expertise in Metal Crushing Technology

In-depth expertise in metal crushing technology is vital for selecting the appropriate machine for specific applications. Different designs offer varied benefits—some machines employ a hammering mechanism, while others use shearing or pressing forces. Operators with specialized knowledge can evaluate factors such as crushing capacity, power requirements, and throughput speed to ensure the chosen machine aligns with project goals.

Advancements in technology have also introduced automated features, such as smart sensors and AI-assisted controls, which optimize crusher operations. Professionals versed in modern tech applications can significantly enhance a facility's productivity and energy efficiency while minimizing manual labor and potential hazards.

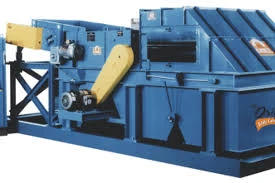

metal crusher machine

Authoritativeness in the Metal Recycling Industry

Professional certification and accreditation serve as indicators of authoritative knowledge in the metal recycling industry. Companies and individuals holding recognized credentials are trusted partners in ensuring compliance with environmental standards and regulations. Emphasizing eco-friendly practices, these authoritative figures contribute to sustainable development through the efficient recycling and reduction of metal waste.

Industry-leading brands often dictate the standards for quality and innovation in metal crusher machines. Collaborating with established vendors ensures access to cutting-edge machinery and support services, contributing knowledge and experience to the overall field.

Trustworthiness and Quality Assurance

The hallmark of a trustworthy metal crusher machine lies in its construction quality and safety features. Machines must be engineered with durable materials to withstand rigorous activity and deliver consistent performance over time. Safety measures, such as emergency shutoff switches, guards, and ergonomic designs, significantly enhance operator safety.

Routine inspection and third-party testing are also fundamental to building trust with customers. Transparent documentation of performance metrics, repair logs, and safety audits ensures accountability and establishes a relationship of confidence with clients. Companies that prioritize customer support, including training and technical assistance, demonstrate their commitment to client success and machine efficacy.

In conclusion, selecting the right metal crusher machine requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. A well-informed approach to machine operation and maintenance not only maximizes productivity but also fosters sustainable practices in metal recycling. As the industry evolves, staying abreast of technological progress and regulatory standards ensures that operations remain efficient and compliant. The synergy of skilled operators, advanced machinery, and established industry partnerships paves the way for excellence in metal waste management.