Metal shredding machines have transformed the landscape of industrial recycling processes. As the global emphasis on sustainable practices increases, these robust devices have become essential tools in the recycling industry. The demand for effective metal shredding technology reflects not just a need for efficiency but also a call for environmentally responsible recycling.

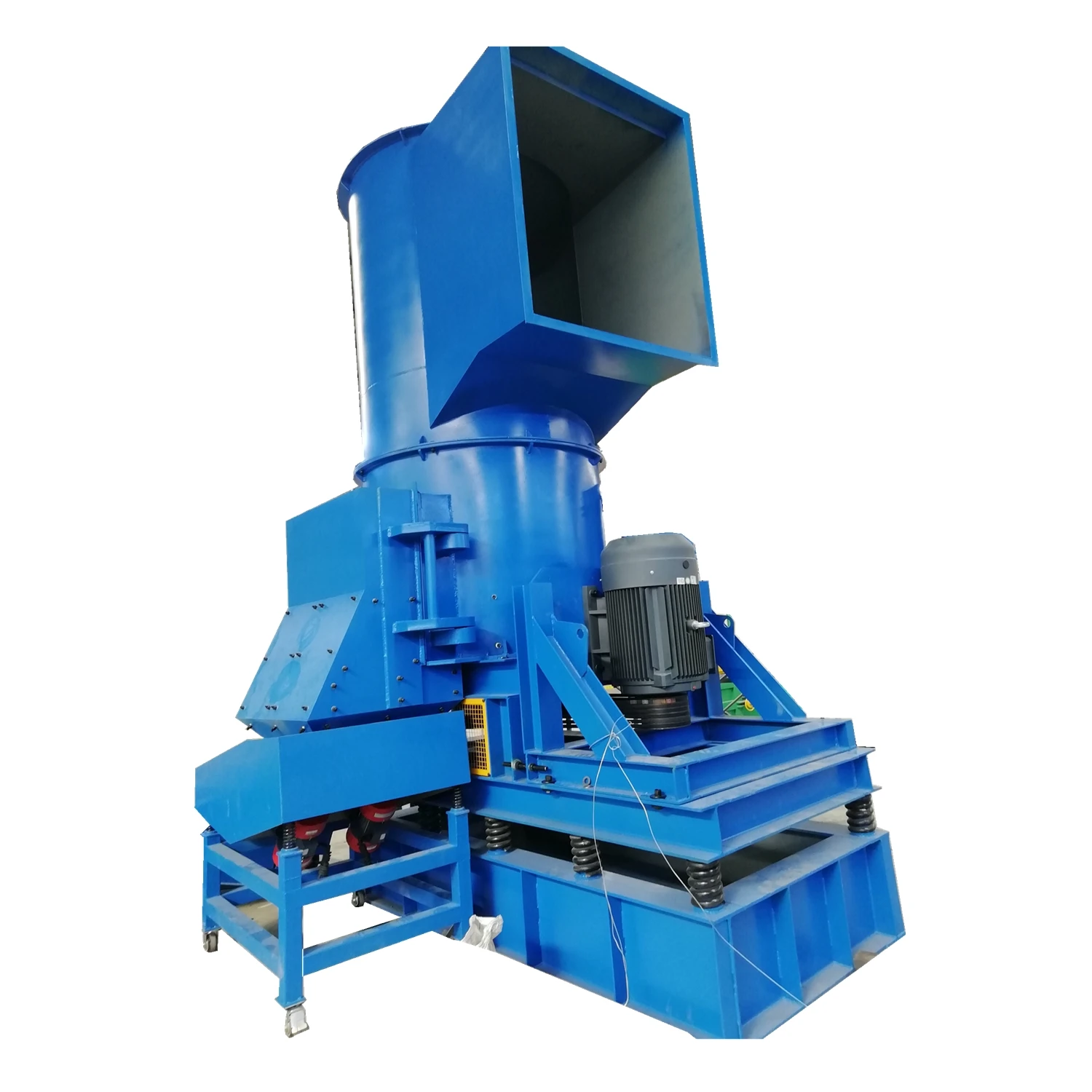

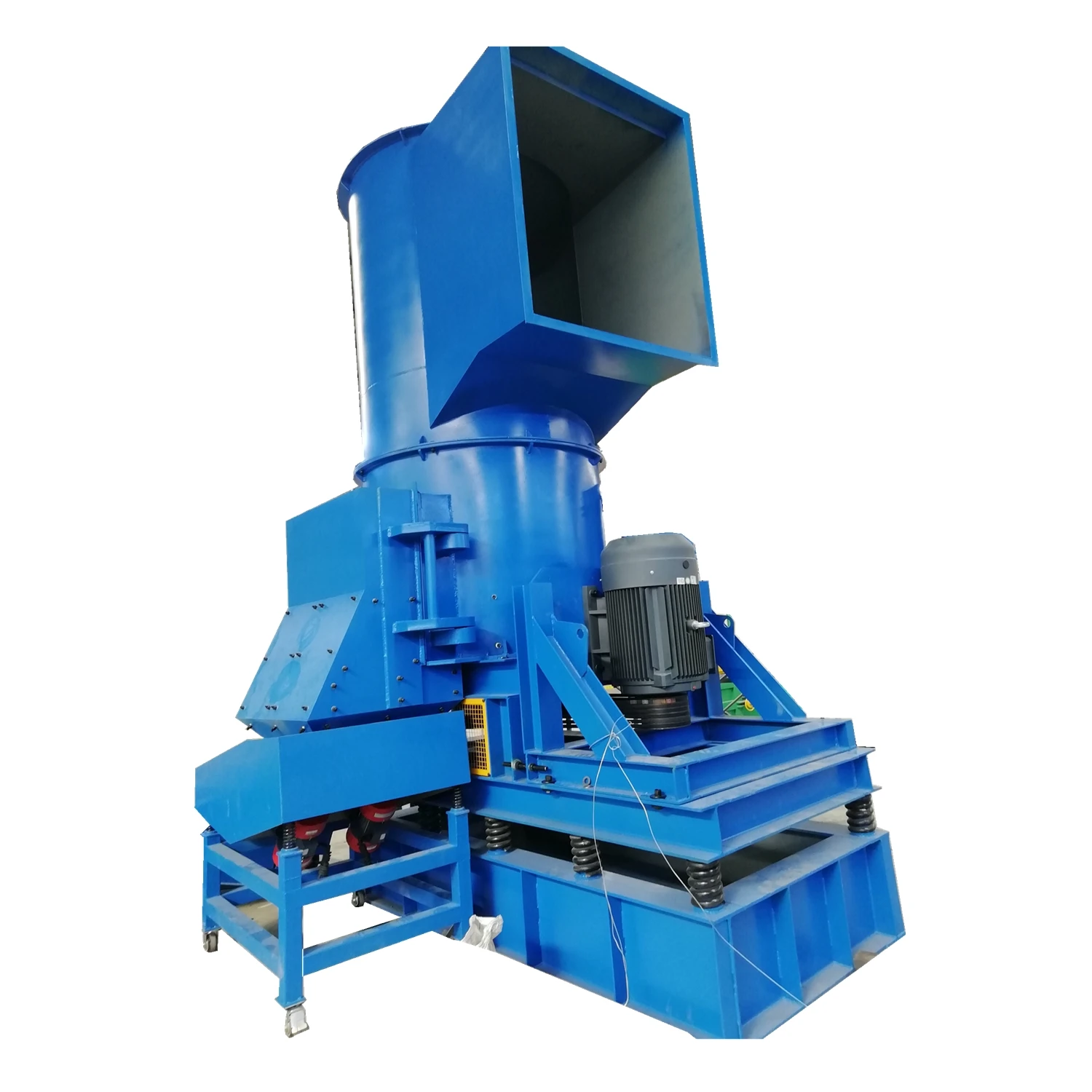

Metal shredders, often referred to as metal shredding machines, are particularly designed to reduce the size of metallic waste into manageable pieces that can be further processed or recycled. Their construction involves high-durability components capable of withstanding the rigorous demands of shredding tough materials such as steel, aluminum, copper, and other metallic waste. The expertise required to design and operate these machines underscores their role as a cornerstone in modern recycling efforts.

Experience with metal shredding machines reveals their importance in both large and small-scale operations. Industrial facilities that manage significant volumes of scrap metal benefit from bespoke shredding systems tailored to their specific needs. These machines not only boost productivity by processing large quantities effectively but also enhance safety by automating processes that would otherwise require hazardous manual intervention.

The expertise behind metal shredding machinery is evident in their advanced features. Many modern shredders come equipped with state-of-the-art technologies that include programmable logic controls (PLCs) for superior operational accuracy, and automated feeding mechanisms to increase throughput. These features ensure that the machines operate at peak performance, offering businesses a reliable solution to their recycling needs. Moreover, they are designed to accommodate a variety of metals, further broadening their application across different sectors.

Authoritativeness in the industry stems from the continuous innovation and research invested into these machines. Companies specializing in metal shredding technology are often at the forefront of innovation, continually enhancing machine capabilities to process even the densest metals. Engaging with leaders in this field allows businesses to leverage cutting-edge solutions that can adapt to changing industry standards and environmental regulations.

machine that shreds metal

Trustworthiness is crucial when considering a metal shredding machine for purchase. Established manufacturers often back their products with comprehensive warranties and after-sales support, ensuring that businesses have access to technicians and specialists when needed. This support network supplements the machine's reliability, providing consistent performance over its operational life. Furthermore, trustworthy manufacturers engage transparently about machine capabilities, limitations, and maintenance needs, ensuring businesses have realistic expectations and maintenance strategies in place.

From a product perspective, metal shredders are designed not only for functionality but also for integration into broader waste management systems. Many shredders are now built with modular designs, allowing for easy upgrades and scalability as business needs evolve. This flexibility ensures that the initial investment in a shredding machine can yield long-term benefits, adapting to increased demands and new types of materials over time.

User testimonials often highlight the drastic improvements in operational efficiency these machines provide. Feedback from experienced operators typically centers around their ease of use, minimal downtime due to robust engineering, and the decreasing need for manual oversight which can significantly cut labor costs. Additionally, environmental benefits are underscored, with metal shredders reducing carbon footprints by optimizing recycling processes and reducing the need for virgin material extraction.

Ultimately, selecting the right metal shredding machine involves an understanding of specific operational needs, available features, and long-term sustainability goals. Businesses that invest in high-quality machinery from reputable manufacturers often find that the benefits extend far beyond immediate operational gains, fostering a more efficient, responsible, and sustainable approach to metal recycling.