Industrial shredders are a game-changer for organizations handling massive quantities of waste or recyclable materials. Designed to dismantle a wide variety of materials, these shredders are vital in industries ranging from recycling and waste management to manufacturing and production. When it comes to large industrial shredders, expertise, precision, and reliability are key, rendering them an investment worth its weight in gold.

The standout feature of large industrial shredders is their robust build tailored for high-volume, high-demand tasks. Often equipped with advanced cutting technologies, these machines consume an array of materials, including metals, plastics, and wood, reducing them into manageable sizes for further processing or disposal. This capability not only streamlines waste management and recycling processes but also significantly reduces overall material handling costs.

The expertise behind designing these shredders is deeply rooted in understanding the diverse challenges associated with different materials. For instance, shredders purposed for metal must withstand incredible resistance without compromising the machine's integrity. Engineers employ sophisticated metallurgy and cutting-edge mechanical designs, ensuring that the shredders retain their cutting efficiency even under relentless operational demands. This meticulous craftsmanship comes from years of studying the behavior of materials under stress and applying this knowledge to create more efficient machines.

In industries where reliability is non-negotiable, these machines are often seen as the authoritative solution. They offer unparalleled operational dependability, reducing downtime that can be costly for large-scale operations. Regular innovations have also equipped modern shredders with smart technology, enhancing their operational efficiency. Features such as self-monitoring systems and automated maintenance alerts bolster their reliability, ensuring continuous and optimal performance.

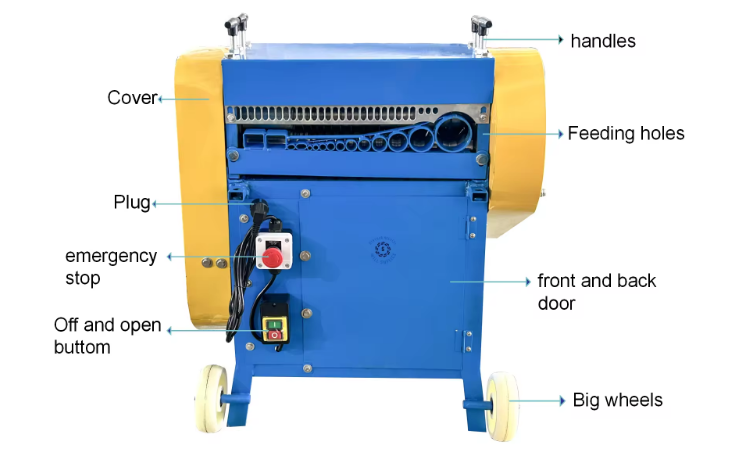

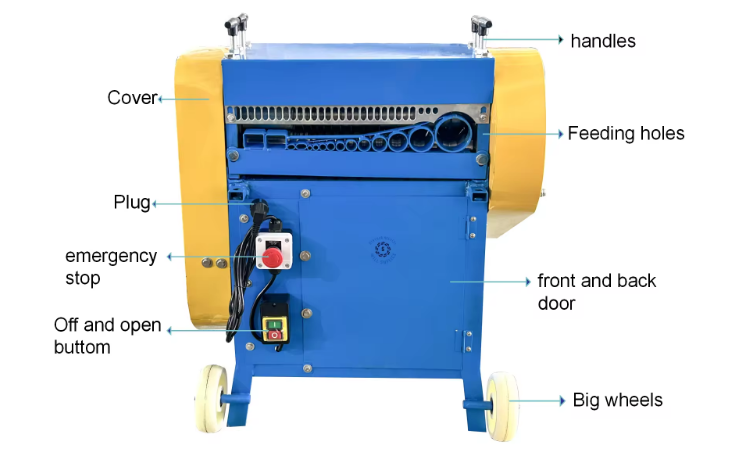

large industrial shredder

Trustworthiness in the context of large industrial shredders is built on the back of compliance with international safety and quality standards. Manufacturers invest heavily in testing and certifying their products, providing users with the assurance that their investments are not only durable but also safe to operate. Shredders are rigorously tested under extreme conditions to meet safety requirements, minimizing the risk of operational hazards.

The real-world experience shared by organizations using these industrial giants highlights remarkable efficiency gains. Case studies from recycling plants have shown that employing large shredders can increase processing capacity by up to 60%, translating into faster throughput and substantial cost reductions. Manufacturing units appreciate the improved waste disposal capabilities, allowing them to maintain leaner, more sustainable operations. These experiences underscore the potential economic and environmental benefits that make large industrial shredders indispensable in modern industrial practices.

To achieve maximal effectiveness, it is crucial to select the right shredder type based on specific industry needs. Expert consultation with manufacturers can provide invaluable insights into the best configurations and sizes, ensuring a fit-for-purpose solution. This bespoke approach not only amplifies operational efficiency but also extends the lifespan of the machinery, securing the investment for years to come.

In conclusion, large industrial shredders are not just machines but pivotal partners in driving industrial efficacy and sustainability. With their expert-backed designs, authoritative presence in the industry, and proven trustworthiness, they encapsulate the essence of modern industrial innovation. Whether your goal is to enhance recycling processes or manage industrial waste more effectively, investing in a large industrial shredder ensures that your operational landscapes remain efficient, safe, and forward-thinking.