Iron shredders have revolutionized the metal recycling industry by optimizing the processing of scrap metal. With an increasing global emphasis on sustainability and efficient waste management, the iron shredder machine stands out as an indispensable tool for industries, enabling the transformation of large metal chunks into manageable pieces. This article delves into the intricate functioning, advantages, and expert insights into the world of iron shredder machines, accentuating its pivotal role in modern waste management and recycling processes.

Iron shredder machines are designed to handle a wide variety of metal materials, including scrap iron, aluminum, copper, and steel. Their configuration allows efficient processing, breaking down large metal pieces into smaller, more manageable sizes for further refining or scrap use. Key to their function are robust rotary shear blades, engineered to withstand high stress while offering significant reduction in size of the ingested materials.

Expert machinists emphasize the importance of selecting the right shredder for your needs. Understanding the distinct types of machines, like single-shaft, dual-shaft, and quad-shaft shredders, can define the efficiency and output. Single-shaft shredders, for instance, are celebrated for their precise cutting efficiency and low noise output, while dual and quad-shaft variations offer versatility and power when dealing with thicker, more resistant metals. Expert insight suggests that choosing an iron shredder aligns with specific operational needs such as desired throughput, types of materials processed, and noise considerations.

In terms of operational economy,

iron shredders excel. These machines are engineered for efficiency, offering high throughput which translates into reduced energy consumption per ton of processed material. Industries utilizing these machines report significant savings in operational costs which, coupled with the income from recycled metal, contributes positively to the bottom line. Furthermore, the longevity of these machines is noteworthy. With proper maintenance—such as routine blade sharpening and motor tune-ups—machines can operate efficiently for years.

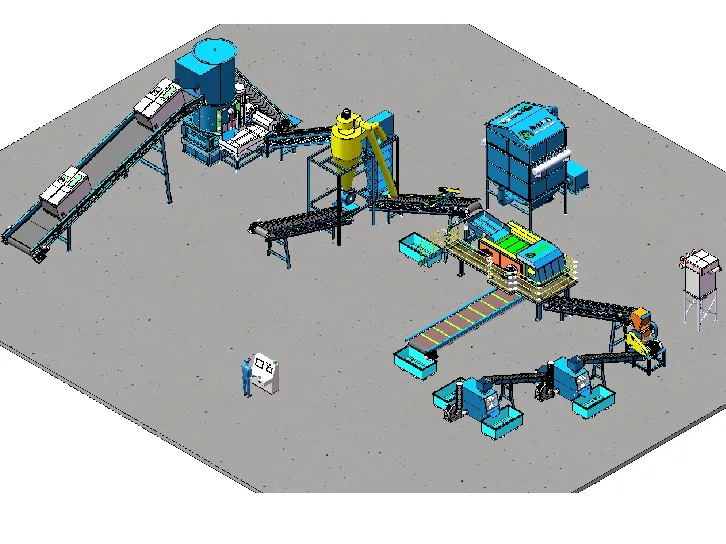

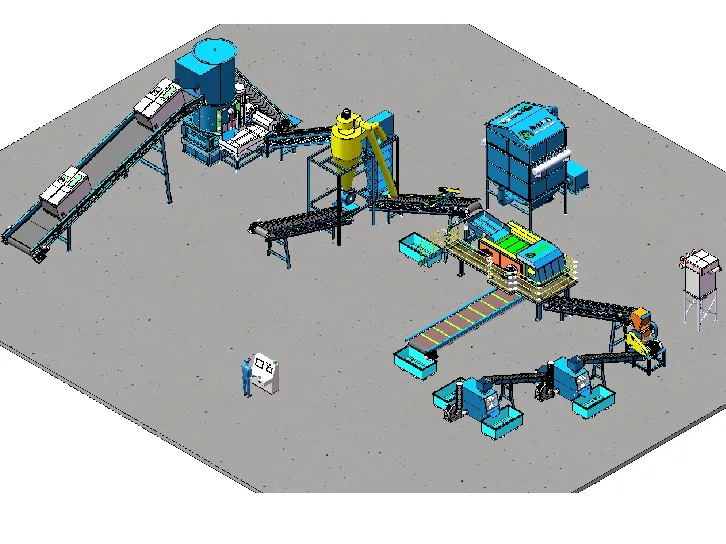

iron shredder machine

From an authoritative standpoint, the role of iron shredder machines in environmental conservation cannot be understated. Metal recycling contributes profoundly to reduced landfill waste and environmental degradation. The extraction of raw materials is resource-intensive and polluting; thus, recycling plays a crucial role in conserving energy and reducing greenhouse gas emissions. Iron shredders are at the forefront, facilitating the efficient recycling process that sees about 400 million tons of metal recycled annually, which equates to significant energy savings and emissions reductions.

The trustworthiness of manufacturers and models is crucial for potential buyers. Top manufacturers offer warranties and maintenance contracts that reassure the buyer of their machine’s longevity and support. Evaluating user reviews and expert insights into different brands and models can provide a reliable guide to making informed purchases, ensuring investments are both strategic and cost-effective.

Implementing iron shredder machinery also poses certain challenges which require adept oversight. Machines must comply with industry safety regulations, ensuring that operators are trained in safety protocols and operational procedures. Industry leaders consistently advocate for strict adherence to these guidelines to mitigate occupational hazards, emphasizing safety as a paramount consideration in the operation of such powerful equipment.

Conclusively, the iron shredder machine is a cornerstone of modern metal recycling and waste management strategies. Its benefits are manifold boosting economic output, contributing to a sustainable environment, and fostering market innovation. The expertise in choosing the right machine, maintaining it thoroughly, and adhering to safety standards enhances both operational and ecological outcomes. An authoritative voice in industry discourse, the iron shredder’s role will continue to expand, underpinning an era where sustainability and economic efficiency are not mutually exclusive but are harmoniously intertwined.