The establishment of an iron recycling plant is a venture that balances both economic opportunities and environmental responsibilities. Understanding the costs involved can aid potential entrepreneurs in making informed decisions. These costs, although varied based on geographical, technological, and operational factors, can be broadly classified into capital investment, operational expenses, and compliance costs.

Capital Investment

The initial financial commitment forms the backbone of any recycling facility and primarily covers land acquisition, plant construction, and equipment procurement. Iron recycling plants require significant space for sorting, processing, and storage of materials, which means that real estate expenses can vary dramatically depending on location. Urban areas might offer proximity to industrial suppliers and consumers but at a higher cost, while rural locations may be more affordable but incur additional logistics costs.

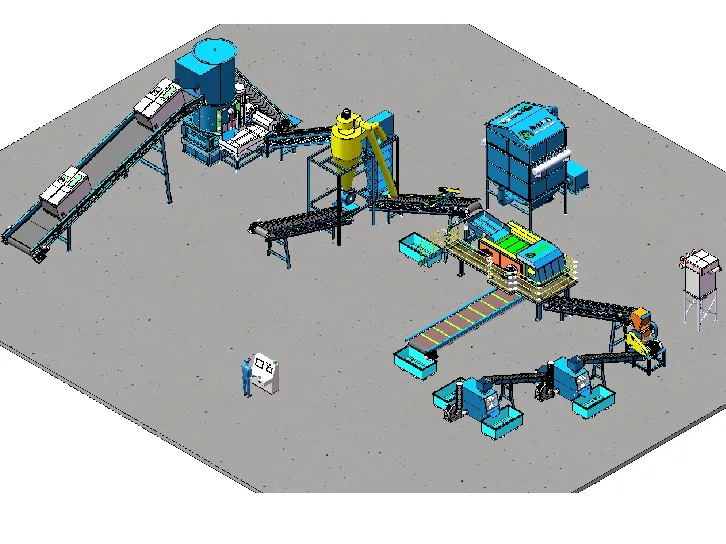

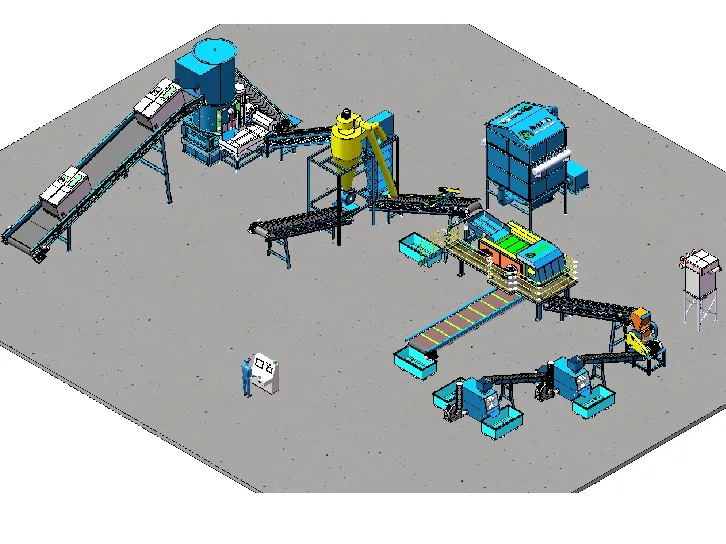

Investing in technology is a critical component. The machinery employed in the recycling process, such as shredders, separators, and smelters, not only determines the quality of the output but also impacts energy efficiency and labor requirements. Advanced technology can lead to substantial cost savings in the long term by minimizing maintenance needs and improving throughput.

Operational Expenses

Day-to-day operational costs include utilities, labor, maintenance, and raw material acquisition. Recycling operations are energy-intensive, making utility costs—electricity, gas, and water—a significant portion of ongoing expenses. Implementing energy-efficient systems and technologies can mitigate these costs effectively and improve overall profitability.

Human resources form another crucial segment of operational costs. The plant requires skilled personnel for operations, quality control, maintenance, and administrative functions. Investing in workforce training enhances productivity and reduces the likelihood of operational hiccups, which can lead to costly downtimes.

Maintenance of equipment is essential for continuous operation. Regular upkeep not only extends the lifespan of the machinery but also ensures compliance with safety and environmental regulations. Given the harsh nature of recycling environments, this becomes a non-negotiable ongoing expense.

Compliance Costs

iron recycling plant cost

Iron recycling plants must adhere to stringent environmental regulations, which vary by region but commonly address emissions, waste management, and workplace safety. The cost of compliance includes permit application fees, emissions monitoring systems, waste management programs, and safety equipment.

Non-compliance can result in hefty fines and operational shutdowns, significantly impacting the plant's reputation and financial standing. Therefore, staying abreast of local and international regulatory changes and investing in eco-friendly technologies is essential.

Revenue Streams and Profitability

An iron recycling plant's revenue is primarily driven by the sale of processed iron to manufacturers. Demand for recycled iron is on the rise as industries seek sustainable raw materials. Pricing, however, can be volatile, influenced by global market trends and economic factors. Diversification in revenue streams, like offering recycling services or producing value-added products, can help stabilize income.

Expert Insights

To achieve success in this industry, continuous investment in technology and human capital is crucial. Adopting innovative recycling methods that maximize material recovery not only enhances profitability but also positions the plant as an industry leader. Networking with suppliers, government bodies, and industry associations can provide valuable insights and business opportunities.

Conclusion

A thorough understanding of the cost structure of an iron recycling plant is vital for its successful operation. Managing these costs through strategic investments and eco-friendly practices will not only ensure financial viability but also contribute to environmental conservation efforts. By aligning business strategies with sustainability goals, plant operators can significantly impact both their bottom line and the planet.