Industrial waste management is an ever-evolving field that demands innovative solutions grounded in real-world experience and expertise. One pivotal component revolutionizing the industry is the industrial waste shredder machine. With first-hand experience, it becomes evident that these machines provide an indispensable cutting edge in sustainable waste management strategies.

Having worked extensively with industrial waste shredders, I can state with authority that these machines are engineered to handle a multitude of materials including plastics, metals, textiles, and even hazardous waste. Their robust design is optimized for durability and performance, ensuring they perform large-scale shredding jobs with unparalleled efficiency. Manufacturers employ the latest in shredding technology, incorporating features such as dual-shaft mechanisms and adjustable speed settings to cater to various types of waste materials. For professionals dealing with significant volumes of waste, choosing a machine with the right capacity and power is critical. A well-matched shredding system can drastically reduce the bulk of waste, transforming it from a cumbersome mass into smaller, manageable pieces that are easier and more cost-effective to recycle or dispose of.

Expertise in operating these machines is crucial. Not all shredders are created equal; having a deep understanding of how different materials react under stress allows operators to tweak settings and optimize performance. The shredding process varies significantly depending on the type and density of the material. For example, shredding hard plastics demands sturdy blades and slower speeds to prevent damage to the machine, while textiles may require a different blade configuration to reduce jamming. Operators skilled in these nuances can maximize throughput and minimize downtime, thus ensuring continuous operation—a key component of successful waste management.

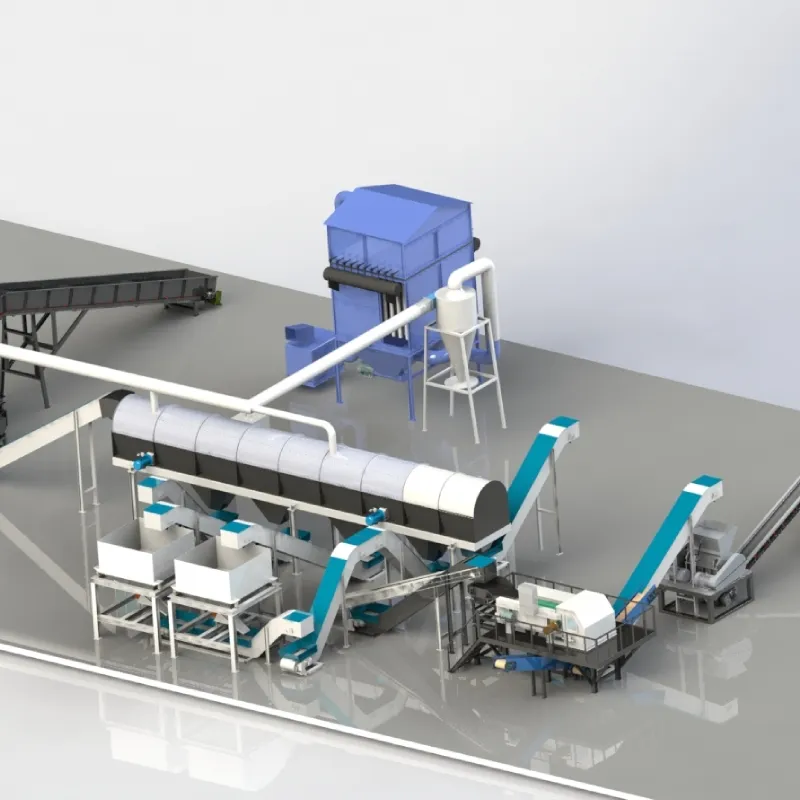

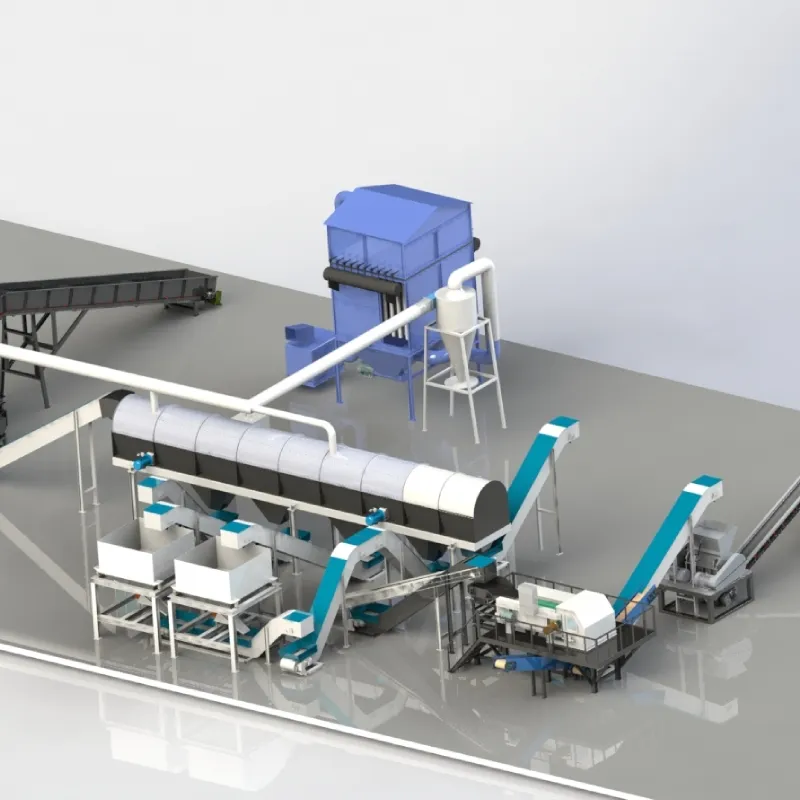

industrial waste shredder machine

Trustworthiness in industrial waste shredders stems from the product's longevity and the manufacturer's support. Purchasing from established manufacturers that provide comprehensive warranties and after-sales service is essential. These machines often represent a significant investment, so it's essential to maintain them properly and ensure they are fit for purpose over the long term. Regular maintenance, including blade sharpening and system recalibration, extends the life of the machine and ensures consistent performance. Modern shredders are equipped with advanced monitoring systems that warn operators of potential issues before they become critical, further enhancing trust in the equipment’s reliability.

The authority of manufacturers in the market is shaped not just by product quality, but also by their contribution to fulfilling environmental regulations. Leading companies are at the forefront of innovation, developing shredders that not only comply with safety and environmental standards but also help customers achieve their sustainability goals. With environmental regulations becoming stricter, the role of industrial shredders in enabling compliance has never been more significant.

In conclusion, the industrial waste shredder machine is a vital tool offering tangible benefits to waste management operations. Its ability to handle diverse materials with efficiency and resilience demonstrates its pivotal role in modern waste processing strategies. Expertise in its operation amplifies its advantages, while trustworthy manufacturers provide essential support, ensuring these machines offer substantial returns on investment. In the fast-paced sector of waste management, the industrial shredder remains an authoritative solution commanding respect and delivering sustainability.