Industrial waste shredders play an indispensable role in waste management across various industries, where efficiency, reliability, and sustainability are paramount. With increasing concerns over environmental impact and the need for efficient waste processing, businesses are seeking advanced solutions to manage their industrial waste effectively. At the forefront of addressing these challenges are industrial waste shredders, which are designed to handle a multitude of waste types, ensuring effective waste reduction and subsequent recycling or disposal.

Experience in choosing the right industrial waste shredder centers around understanding the specific needs of your business. It is crucial to consider the type and volume of waste your industry generates. For instance, industries such as manufacturing, automotive, and construction produce diverse waste materials ranging from plastics, metals, wood, to textiles.

Each of these materials demands specific shredding technologies to maximize efficiency and minimize downtime. First-hand accounts from businesses using the right shredder models have shown significant reductions in overall waste management costs and enhanced operational efficiency.

Expertise in industrial waste shredders involves a deep understanding of the technology and mechanics behind them. Modern shredders are outfitted with smart technology, allowing for precise control and automation. Features such as automatic feeding, output size control, and energy-efficient motors drastically improve performance. Shredder designs are typically categorized into primary, secondary, and tertiary shredders, each serving a unique purpose in the waste processing chain. Experts in waste management emphasize the importance of integrating shredders with existing waste processing systems to optimize the entire workflow.

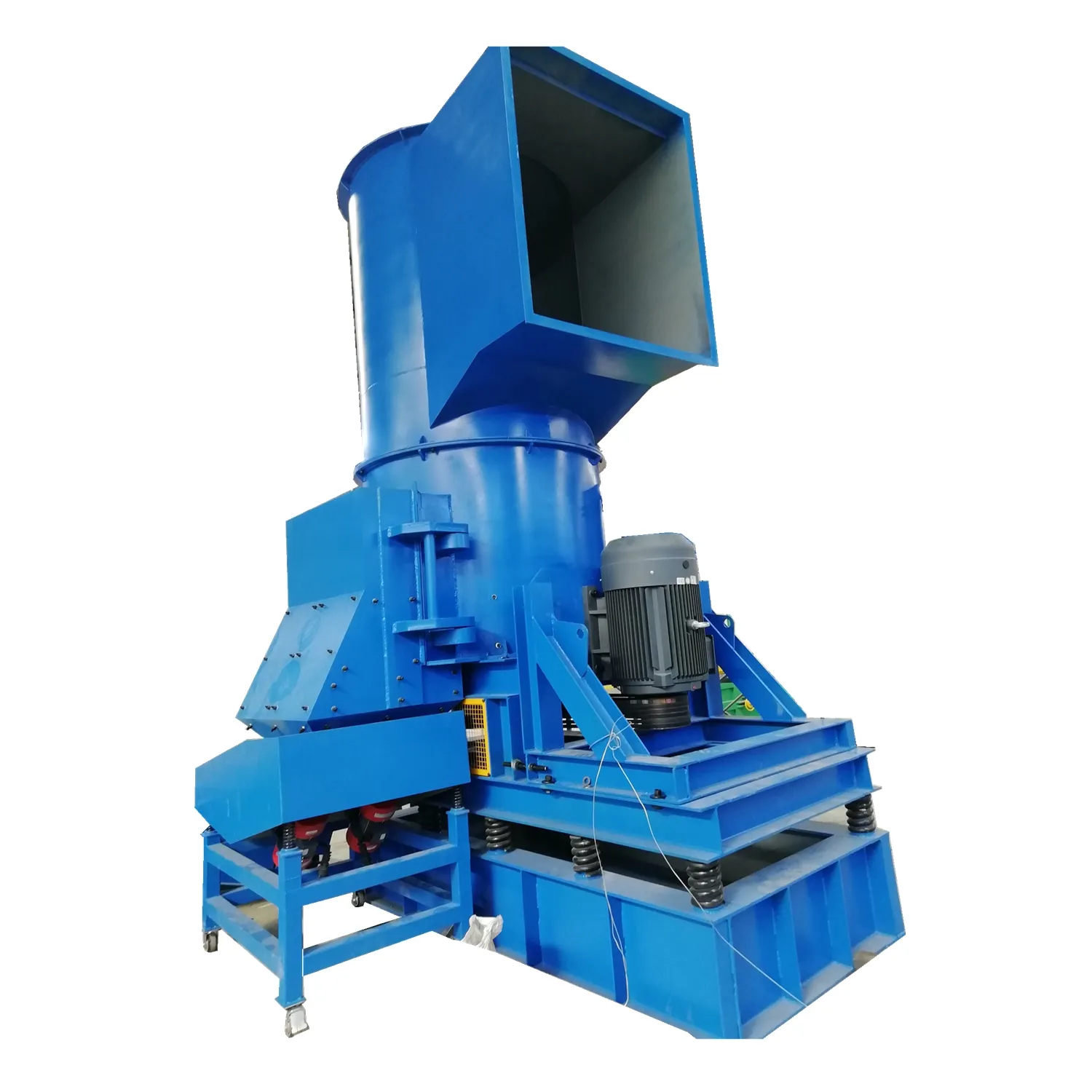

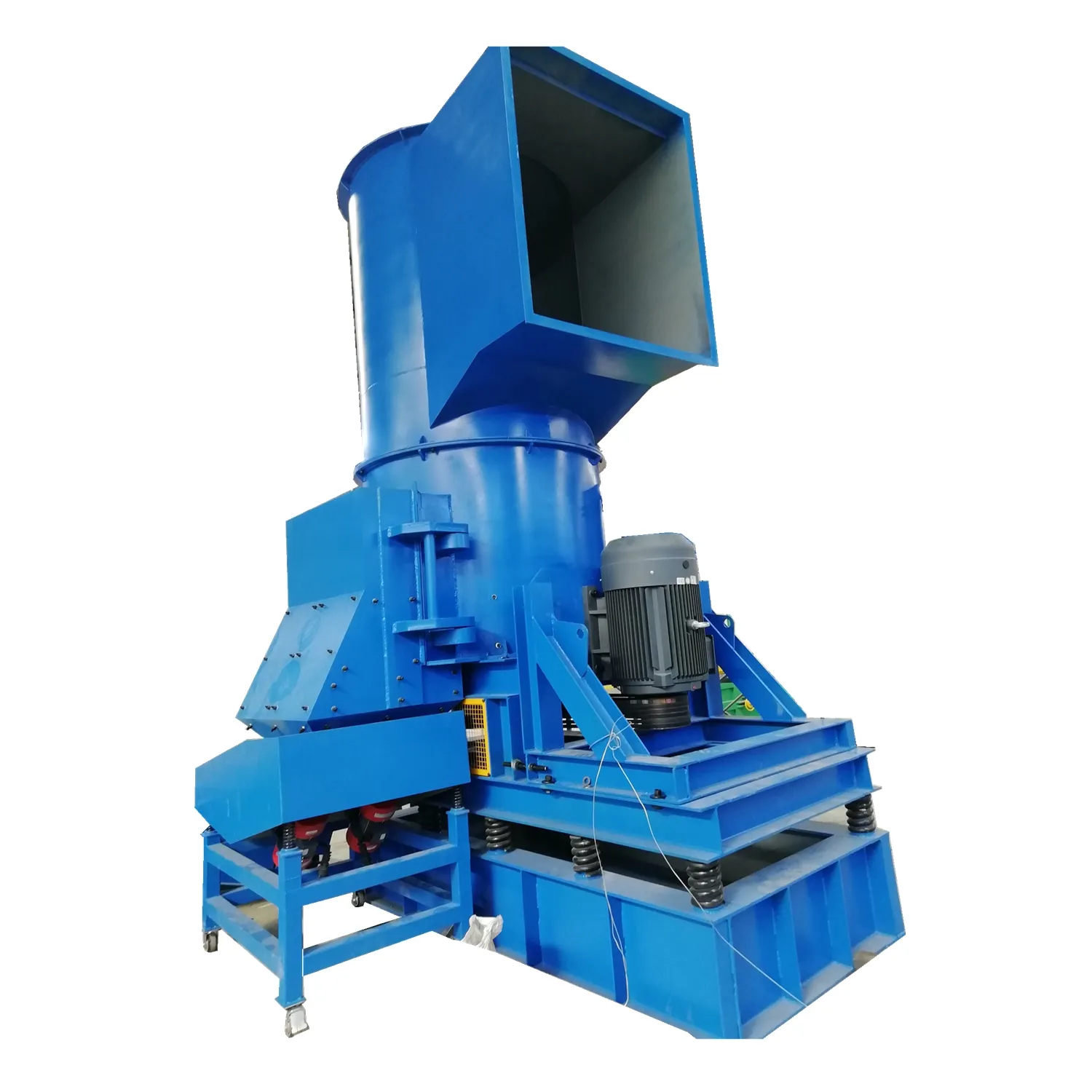

industrial waste shredder

Authoritativeness in the sphere of industrial waste shredders is asserted by industry leaders and manufacturers who continuously innovate and improve shredder designs to meet regulatory standards and environmental guidelines. Companies at the helm of shredder production often participate in global forums and collaborate with environmental agencies to ensure their products not only deliver on performance but also contribute to sustainability goals. The adherence to international safety and environmental standards gives these companies an edge, establishing trust among clients who prioritize environmentally responsible waste management solutions.

Trustworthiness of industrial waste shredder providers is built on a foundation of proven performance and customer satisfaction. It is imperative for businesses to select vendors with a reputation for reliability and performance. Testimonials from existing clients and case studies highlighting successful implementations provide a window into the real-world application and benefits of employing such systems. Reliable vendors also offer comprehensive after-sales services, including maintenance, spare parts availability, and technical support, ensuring the longevity and efficiency of the shredder equipment.

In conclusion, industrial waste shredders represent a critical component in modern waste management strategies. By choosing the right shredder tailored specifically to business needs, companies can significantly contribute to reducing their environmental footprint while enhancing operational efficacy. Investing in advanced shredder technology ensures not only compliance with environmental standards but also offers a competitive advantage in sustainable business practices. As industries worldwide grapple with increasing waste management challenges, partnering with experienced, expert, authoritative, and trustworthy shredder providers becomes an essential strategy.