Industrial steel shredders have revolutionized the recycling and waste management sectors through their strength, efficiency, and versatility. These powerful machines are designed to transform bulky steel scraps into smaller, reusable materials, ultimately reducing waste and promoting sustainability. As industry demands continue to grow, understanding the intricacies of industrial steel shredders is crucial for businesses seeking to optimize their operations.

The mechanics of industrial steel shredders revolve around their cutting-edge design, which incorporates robust blades and powerful motors. These shredders are capable of processing large volumes of steel with varying thicknesses. The versatility of the shredders is achieved through customizable settings, allowing operators to adjust speed, torque, and blade configurations based on the type of steel being processed. This adaptability not only increases efficiency but also enhances the longevity of the equipment by minimizing wear and tear.

From an expertise standpoint, selecting the right industrial steel shredder requires a thorough analysis of specific business needs. Shredders vary in dimensions, energy consumption, and output capabilities, and choosing the right model can have a significant impact on operational efficiency. Experts often recommend assessing the average size and thickness of the steel materials to be processed, as well as the desired output size of the shredded steel. Businesses must also consider the ease of maintenance and availability of parts to avoid prolonged downtime, which could lead to increased costs and lost productivity.

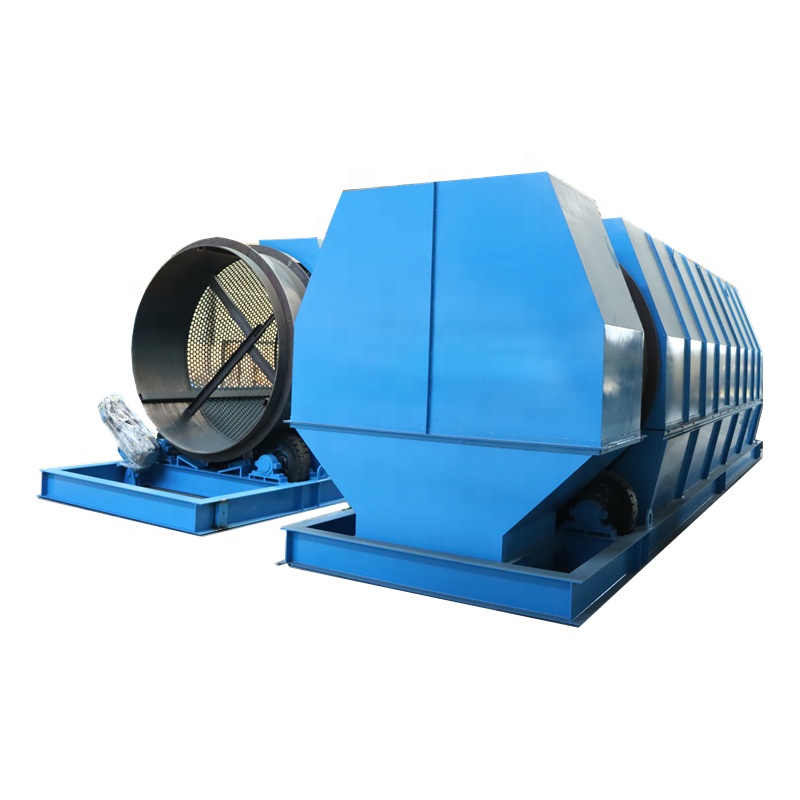

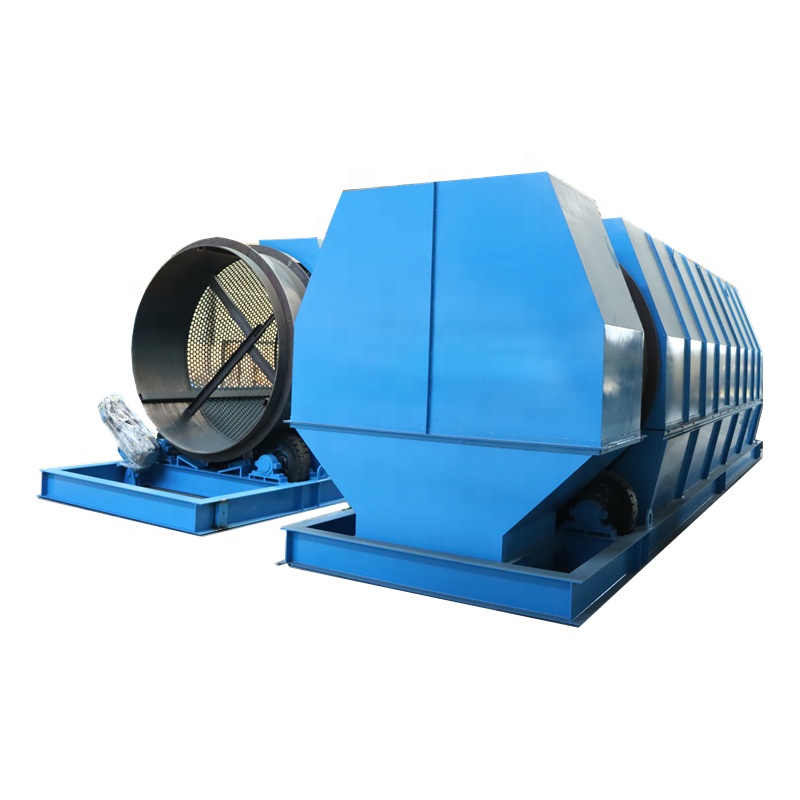

industrial steel shredder

Further demonstrating authority in the subject, industry standards and regulations must be adhered to when operating these machines. Compliance with safety standards not only ensures the safety of the operators but also enhances the machine’s performance. Many established manufacturers offer training sessions and thorough instruction manuals, equipping operators with the necessary skills to safely and effectively use these machines. Engaging with these educational resources is critical for businesses to maintain a competent workforce capable of maximizing the shredder’s capabilities.

The trustworthiness of industrial steel shredders is often reflected in testimonials from satisfied customers. Companies that have successfully integrated shredders into their recycling processes frequently report reduced operational costs, increased revenue from recycled materials, and a marked improvement in environmental impact. Peer reviews and industry accolades further bolster the reputation of leading shredder models, providing new customers with peace of mind regarding their investment.

In conclusion, the industrial steel shredder stands as a testament to technological advancement and environmental responsibility. The combination of experience and expertise ensures that these machines are not only efficient but also safe and reliable. By investing in a high-quality shredder and committing to regular maintenance and training, companies can establish themselves as leaders in the sustainable management of steel resources. As global industries recognize the value of reducing waste through recycling, steel shredders will continue to play a pivotal role in shaping a more sustainable future.