Industrial shredding equipment is revolutionizing waste management and material processing in numerous industries. As the demand for efficient, reliable, and versatile machinery increases, businesses are actively seeking equipment that not only meets their operational needs but also complies with environmental regulations and enhances productivity. This article explores key considerations in choosing industrial shredding equipment, examining real-world experiences, expert insights, authoritative guidance, and trustworthy assessments that can guide purchasing decisions.

Choosing the right industrial shredding equipment begins with understanding the specific requirements of your industry. Whether dealing with bulky woods, metals, plastics, or paper, each material necessitates a machine capable of handling its unique properties. In waste management, shredders that accommodate varied waste streams while optimizing output are crucial. Companies involved in metal recycling, for instance, require robust machines that withstand high resistance and efficiently process different metal types without compromising throughput.

Expertise in industrial shredder technology is indispensable. Consulting manufacturers who specialize in custom solutions can provide equipment tailored to specific operational demands. Industry leaders such as SSI Shredding Systems and UNTHA offer a range of customizable options, supported by extensive research and development, ensuring that each piece of machinery aligns with precise client specifications. These manufacturers often provide detailed training for operator safety and machine maintenance, underscoring the importance of expert guidance in achieving optimal performance and longevity.

Authoritativeness in the field of shredding equipment is often demonstrated through certifications and adherence to industry standards. Equipment that adheres to ISO 9001 certification, for example, guarantees a standardized level of quality management, ensuring operations meet greater efficiency and reliability. Moreover, certifications related to environmental management (ISO 14001), health, and safety further reinforce the equipment's credibility, supporting businesses in achieving sustainable practices.

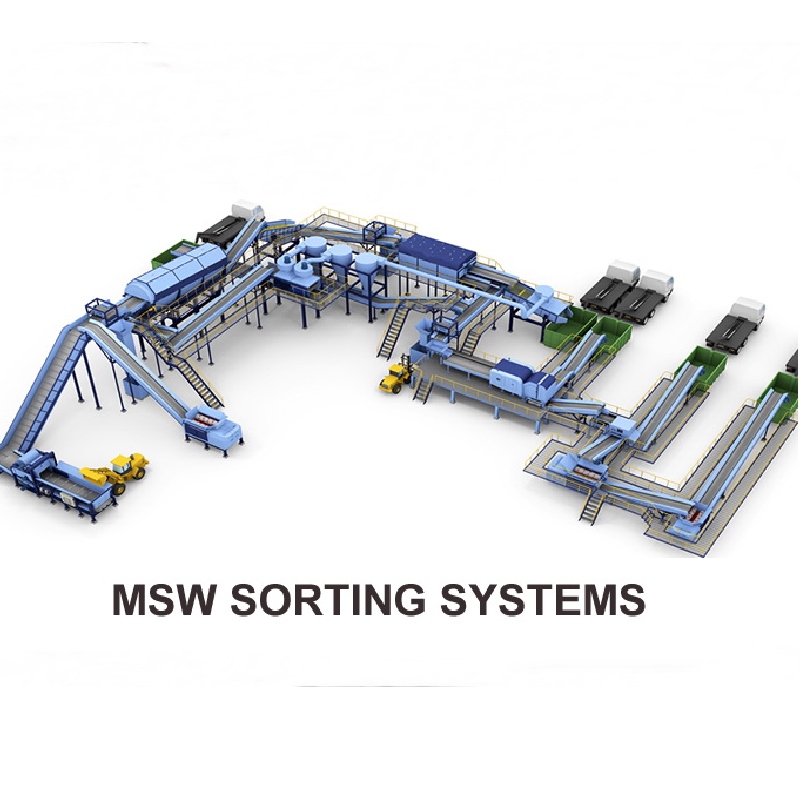

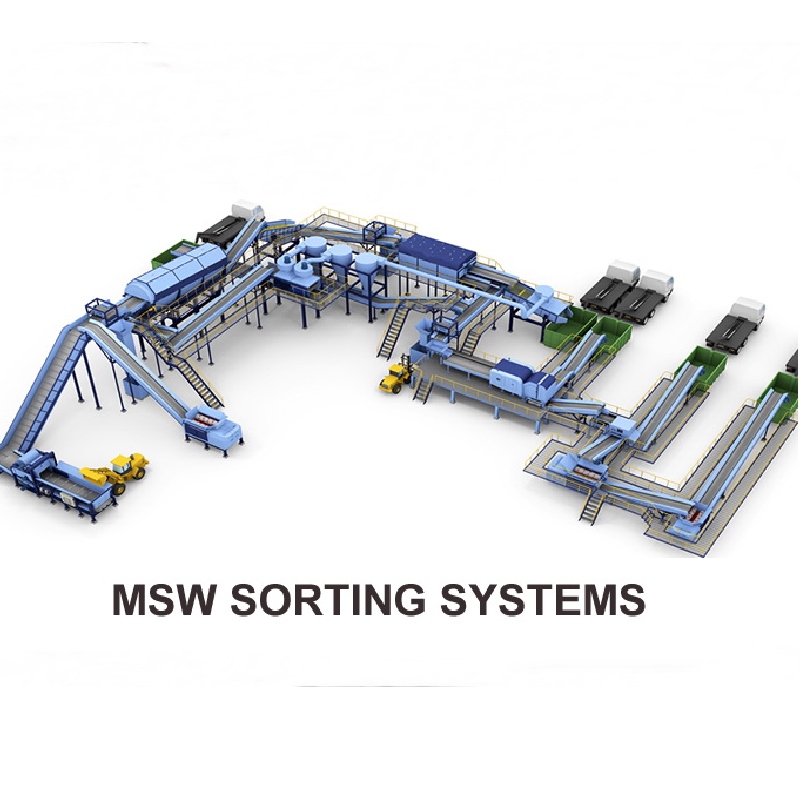

industrial shredding equipment

Trustworthiness in equipment providers is paramount. Customer testimonials, service history, and post-sale support are vital indicators of a manufacturer's reliability. A dependable provider offers comprehensive warranties and is transparent about the lifespan and maintenance needs of their machines. Partnerships with such providers foster confidence, ensuring that businesses receive both the technical and customer support necessary throughout the equipment lifecycle.

Finally, real-life experiences offer invaluable insights into the performance and reliability of industrial shredding equipment. Case studies highlighting successful applications of shredders within different sectors shed light on their operational impact. Whether enhancing recycling rates in a municipality or streamlining production waste in manufacturing, these cases reflect the tangible benefits of investing in high-quality shredding equipment.

In conclusion, selecting the appropriate industrial shredding equipment involves a combination of tailored solutions, expert input, certified quality, and reliable service. By prioritizing these factors, businesses not only optimize their material processing capabilities but also align with sustainable practices, ultimately contributing to a healthier environment and more efficient industry operations. Making informed decisions based on experience, expertise, authoritativeness, and trustworthiness ensures long-term success and innovation in waste management and material processing sectors.