Industrial shredders for metal processing are essential components in modern recycling and waste management facilities. These robust machines play a critical role in reducing metal waste into manageable, recyclable sizes, facilitating increased recycling rates and promoting environmental sustainability.

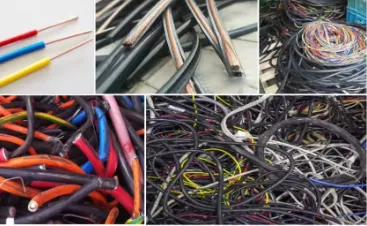

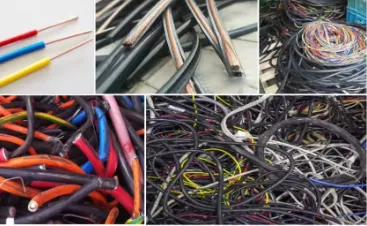

Metal shredders are specifically engineered to handle various metal types, whether it be aluminum, copper, or heavier, more robust materials like steel. Their primary function is to transform large, cumbersome metal materials into smaller, more manageable pieces. This process not only aids in efficient storage and transportation but also enhances the recycling process by ensuring metal is cleanly and uniformly broken down.

When considering an industrial shredder for metal, potential buyers should consider several technical specifications to suit their specific processing requirements. The material's throughput, the machine’s capacity to handle different metal thicknesses, and the speed at which material can be processed are all critical factors. Businesses should assess their volume needs to choose a shredder that can keep up with their operational demands while maintaining optimal performance.

Additionally, the design and quality of the shredder blades are of paramount importance. Industrial shredders feature specially designed blades capable of handling tough metals without wearing out too quickly. High-quality blades, often made from hardened steel, can operate longer without needing replacement, thereby reducing downtime and maintenance costs. It's essential to choose shredders with easily replaceable and high-durability blades for continuous operation.

Safety is another critical attribute of industrial shredders. Modern shredders are equipped with numerous safety features to protect operators and ensure the safe processing of materials. Automatic shut-off mechanisms, safety switches, and enclosed shredding chambers are common features that prevent accidents and protect workers from the machine’s mechanical operations.

industrial shredder metal

One must also consider the technological advancements driving the metal shredding industry. Many industrial shredders now incorporate advanced control systems with interactive user interfaces that allow operators to fine-tune operations. These systems provide real-time data and analytics on machine performance, energy consumption, and maintenance schedules, enabling companies to optimize processes and reduce operational costs.

Emission control and reduction of environmental impact play an increasingly significant role in choosing industrial shredders. Forward-thinking manufacturers are developing eco-friendly models that decrease emissions, noise levels, and energy consumption. Companies striving for sustainability would benefit from investing in shredders equipped with these eco-centric features to align with green policies and reduce their carbon footprint.

Selecting the right industrial shredder also involves understanding compliance with regulatory standards. Quality manufacturers ensure their shredder models comply with industry standards and governmental regulations. This compliance guarantees that machines not only deliver performance but also meet legal and environmental requirements.

For businesses that deal with scrap metal, investing in an industrial metal shredder is a strategic decision that yields long-term benefits. These machines not only streamline waste management but also offer significant cost savings by reducing the volume of waste and optimizing the recycling process. Besides, choosing a reliable shredder serves to enhance productivity and safety within the workplace, providing peace of mind for business owners and operators alike.

In conclusion, industrial shredders for metal are indispensable in today's waste management landscape. These machines offer actionable solutions to managing metal waste efficiently, optimizing recycling processes, and fostering sustainability. Careful selection, focusing on capacity, safety, technological features, and regulatory compliance, will ensure that the chosen shredder meets both current and future operational needs. Therefore, a well-chosen industrial shredder is not just an asset but a strategic investment towards operational excellence and environmental responsibility.