Understanding the Pricing Dynamics of Industrial Shredder Machines

Industrial shredder machines are indispensable assets for businesses involved in waste management, recycling, and various manufacturing processes. These robust machines are designed to shred materials such as wood, plastic, metal, and paper into smaller pieces, facilitating easier handling and disposal. When considering the purchase of an industrial shredder machine, it's crucial to understand the factors that influence their pricing. This knowledge ensures an informed decision that aligns with your operational needs and budgetary constraints.

The first and foremost factor impacting the price of industrial shredders is their size and capacity. Machines with higher throughput capabilities generally command higher prices. Businesses must assess their volume of materials that need processing and choose a machine that can handle the load efficiently. Overestimating capacity might lead to unnecessary expenses, while underestimating can result in operational bottlenecks.

Material types that industrial shredders are designed to handle also play a significant role in pricing. Machines that can shred tougher materials such as metals or thick plastics are often equipped with more durable and complex cutting systems, which are more expensive to manufacture and maintain. Versatile shredders that handle multiple material types may offer long-term value for businesses engaged in diverse processing tasks.

Another crucial determinant is the technology and features incorporated into the shredder. Advanced shredders come with features like automated feeding systems, noise reduction technologies, and smart controls for optimized performance and safety. While these add-ons enhance operational efficiency and ease of use, they also contribute to higher upfront costs. Nevertheless, investing in technologically advanced shredders can lead to cost savings in terms of labor and operational downtime in the long run.

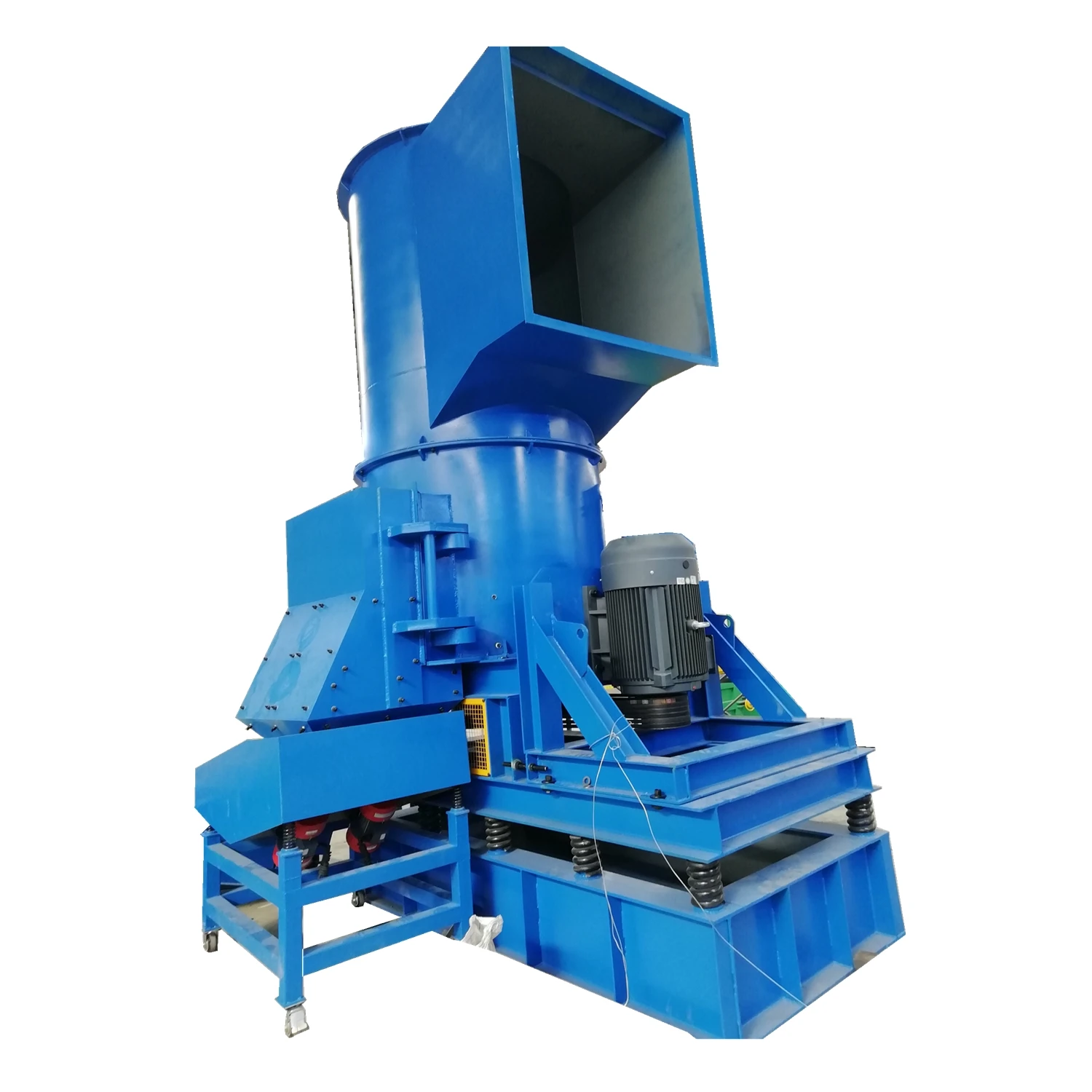

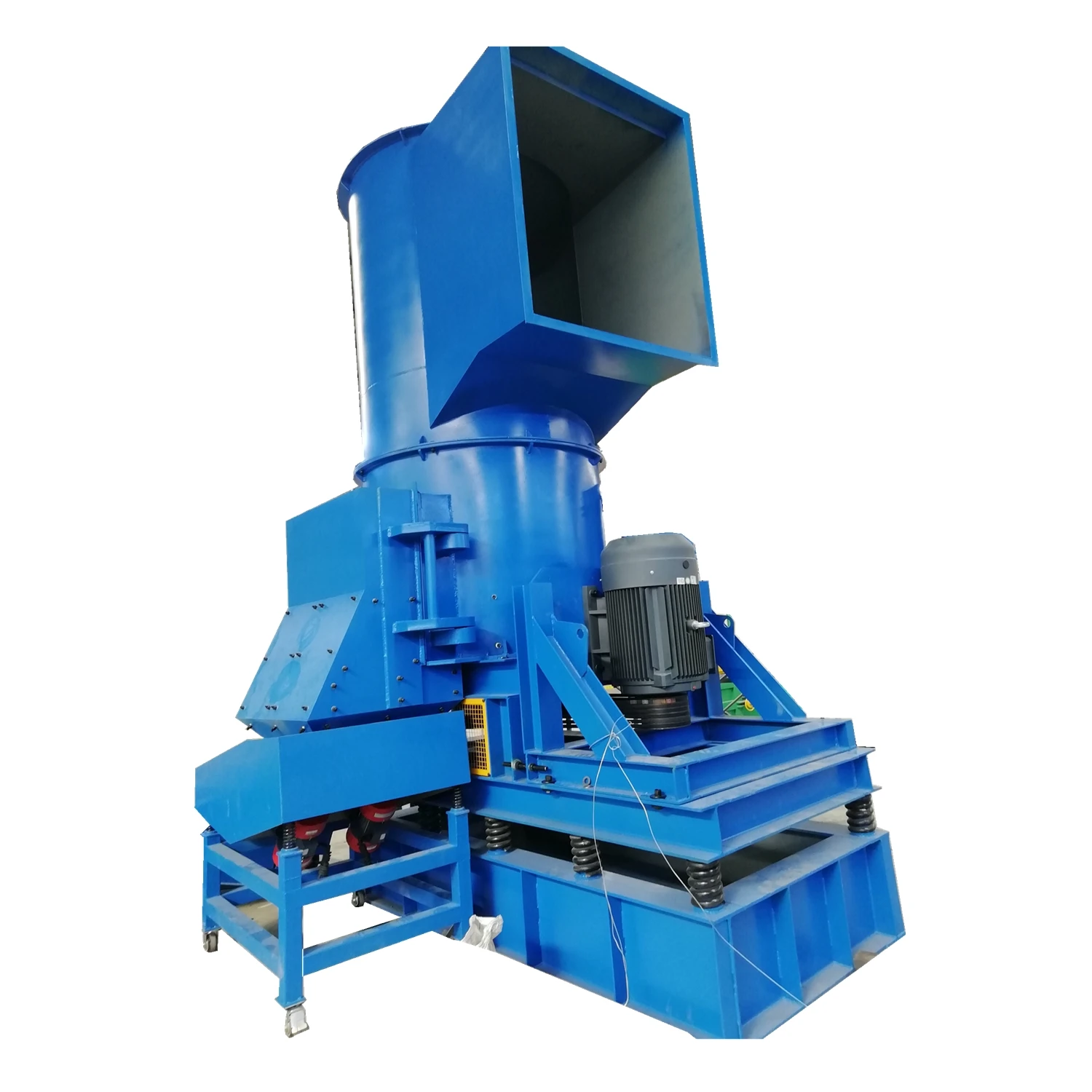

industrial shredder machine price

The brand and manufacturer reputation significantly influence the price as well. Established brands with a track record of reliability and efficient after-sales service often charge premium prices. These companies invest heavily in research and development to ensure their products meet industry standards and regulatory requirements. Opting for well-known brands can enhance trustworthiness, assuring buyers of product quality, spare part availability, and technical support.

Economic factors such as demand and supply dynamics, as well as raw material costs, can affect the price of industrial shredders. During periods of high demand, prices might escalate, whereas oversupply situations often lead to competitive pricing. Additionally, fluctuations in the cost of steel and other inputs used in the manufacturing process can directly impact shredder prices.

Finally, potential buyers should consider the total cost of ownership (TCO) rather than just the purchase price. This encompasses maintenance, energy consumption, and potential downtime costs. A machine with a lower initial price might incur higher operational expenses, negating any upfront savings. Therefore, it's crucial to analyze the long-term financial implications of the shredder machine purchase.

In conclusion, while the initial outlay for an industrial shredder machine is a significant consideration, understanding the various factors that influence pricing is vital for making a sensible purchase. Assessing the machine's capacity, durability, technological advancements, brand reputation, and total cost of ownership can guide buyers in selecting a shredder that provides the best value for their investment. Wise decision-making in this regard not only enhances operational efficiency but also promotes sustainable and cost-effective business practices.