Exploring Industrial Shredder Costs A Comprehensive Guide

Industrial shredders play a crucial role in waste management and recycling processes across various industries. However, their costs can often be a source of confusion. Armed with genuine insights, expert knowledge, and a focus on credibility, this guide delves into the factors affecting industrial shredder costs and how to make informed purchasing decisions.

Understanding the Varied Costs

Several elements influence industrial shredder cost, making it essential for buyers to understand what they are investing in. These factors range from build quality and capacity to advanced features and service agreements.

1.

Type and Capacity

The cost largely depends on the type of industrial shredder. For instance, single-shaft shredders typically cost less compared to multi-shaft variants due to their simpler design. Yet, multi-shaft shredders offer enhanced versatility, handling more complex materials, which can justify their higher price.

Capacity is another critical factor. A shredder capable of handling several tons per hour will obviously be priced higher than a smaller model. Manufacturers often offer machines in a range to match your specific needs.

2. Build Quality and Materials

The longevity and efficiency of an industrial shredder are directly tied to its build quality. Opting for durable materials like hardened steel can cut down long-term maintenance costs significantly. Quality comes at a price, yet the return on investment in avoiding frequent repairs or replacements cannot be overstated.

3. Motor Power and Efficiency

Shredders with high-horsepower motors are essential for handling more demanding shredding tasks or tougher materials. Such machines tend to be more expensive upfront but provide faster processing and efficiency gains in the long run. Evaluating energy efficiency and operational costs is vital to understand the ongoing financial commitment.

4. Advanced Features

Additional features can increase the price. Some shredders come with sophisticated control systems for easier operation, automated maintenance alerts, and innovative technologies to enhance safety. These features can be an advantage, reducing labor costs and minimizing operational risks.

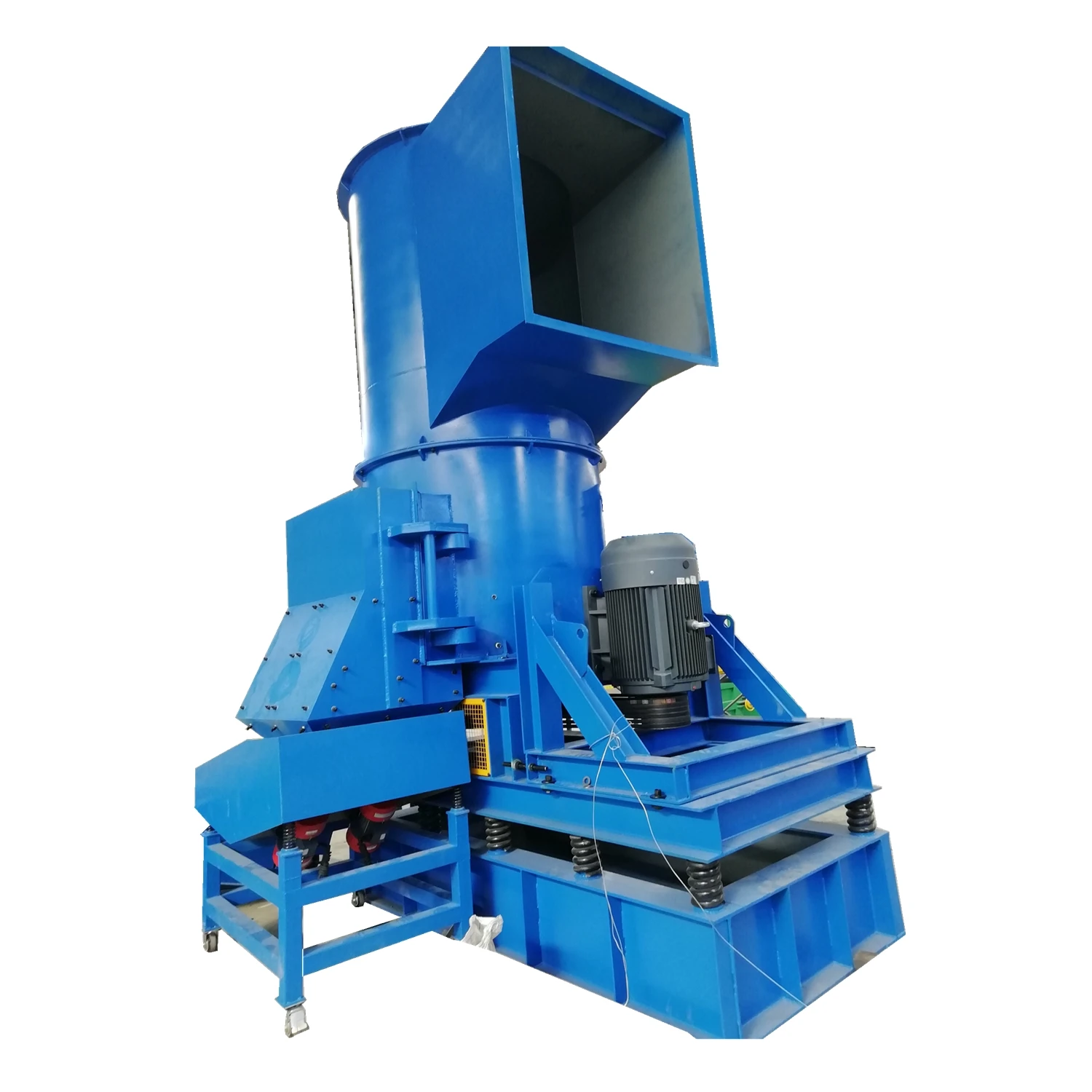

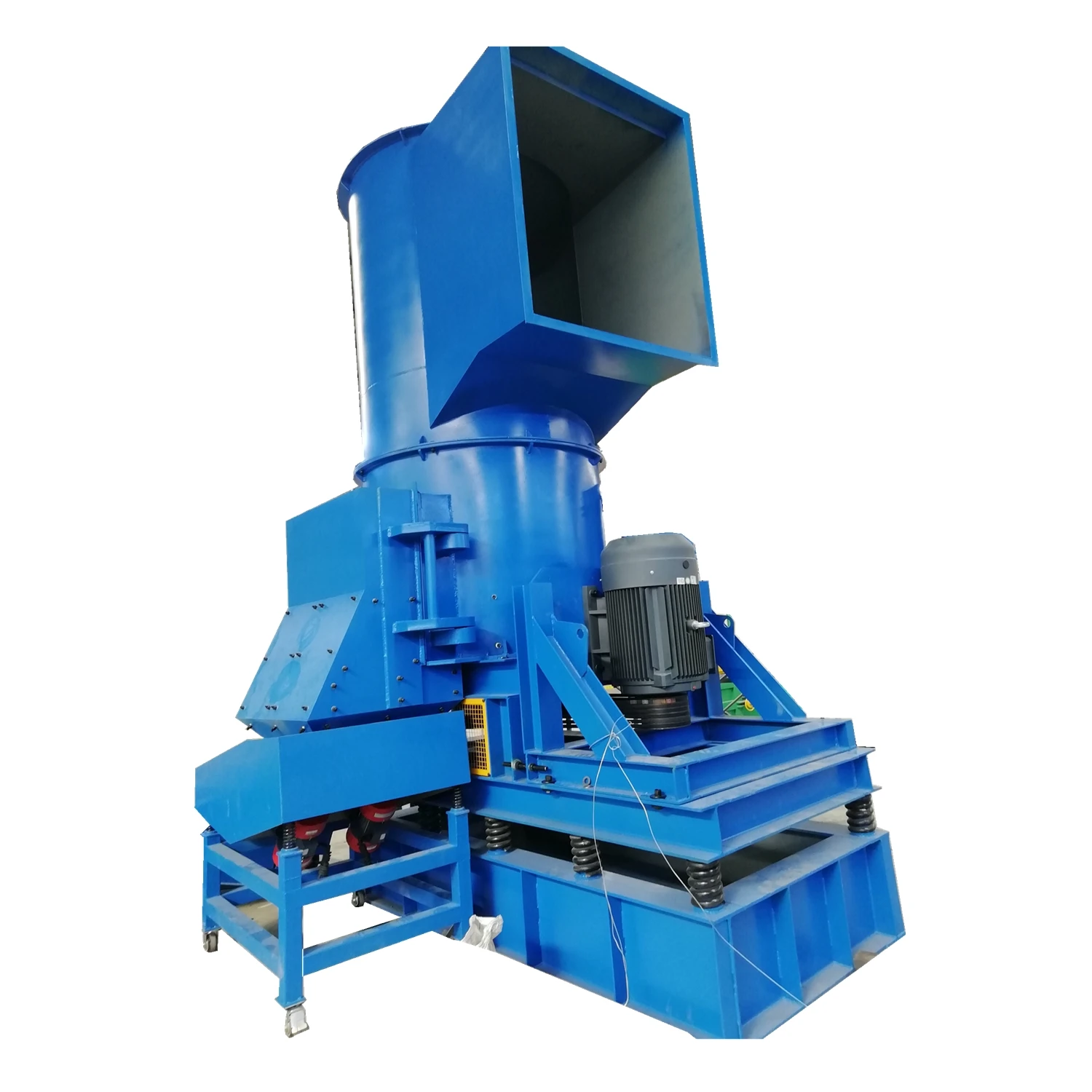

industrial shredder cost

5. Installation and Service Agreements

Installation costs are often overlooked but can add to the initial expenditure. An efficient installation ensures optimal performance. Consider service agreements, which might include regular maintenance, emergency repairs, and parts replacement. These services often justify initial higher costs by preventing future breakdowns and costly downtimes.

Expert Perspectives on Buying Decisions

Consulting industry experts can pay dividends when selecting an appropriate shredder. Professionals bring insights from past market trends, potential technological advancements, and a profound understanding of operational efficiencies. Attending industry seminars or speaking with established manufacturers can provide actionable data for a purchase.

Real Experience and Endorsements

Engaging with industries that have experienced successful shredder usage adds to the validation process. Case studies or testimonials from similar businesses offer practical perspectives. These narratives might highlight overlooked aspects like customer service quality or unexpected maintenance savings, which can profoundly affect user satisfaction.

Trust and Authoritativeness in Choices

Quality suppliers focus on building trust through transparency, longevity, and consistent improvements. Reviewing ISO certifications, awards, and industry accreditations helps ascertain a vendor's credibility. Trustworthy manufacturers further back their products with strong warranties and customer support systems.

Making An Informed Decision

Before investing, conduct a comprehensive analysis of your shredding needs versus the offerings available in the market. Consider future scalability and the potential emergence of newer technologies. Factoring in total cost of ownership—purchase price, operational costs, and maintenance—will guide you in choosing a shredder that aligns with both your budget and operational objectives.

Conclusion

The intricacies of industrial shredder costs demand a nuanced approach. Balancing initial investment with long-term benefits, while ensuring quality and efficiency, is vital. By leveraging expertise, trusted manufacturers, and real-world experiences, buyers can confidently navigate the market to secure shredders that meet their industrial needs seamlessly.