Recycling printed circuit boards (PCBs) is an intricate process that involves a blend of expertise, cutting-edge technology, and a commitment to sustainable practices. As e-waste continues to grow exponentially, understanding how to responsibly recycle PCBs is crucial for both environmental preservation and resource recovery. This guide will delve into the practical approach to PCB recycling, offering insights from seasoned professionals who have mastered this complex endeavor.

Printed circuit boards are found in virtually every electronic device imaginable, from smartphones to laptops, and even complex industrial machines. These boards contain a myriad of precious metals, including gold, silver, and palladium, alongside valuable base metals like copper and aluminum. The challenge lies in separating these valuable components from harmful substances like lead and brominated flame retardants, which are commonly found in older PCBs.

The Recycling Journey

PCB recycling begins with the collection phase, a step that requires the cooperation of individuals, companies, and municipalities. Ensuring that PCBs are directed to certified recycling facilities is vital to prevent hazardous waste from polluting the environment. These facilities are equipped with advanced machinery and adhere to stringent safety and environmental standards.

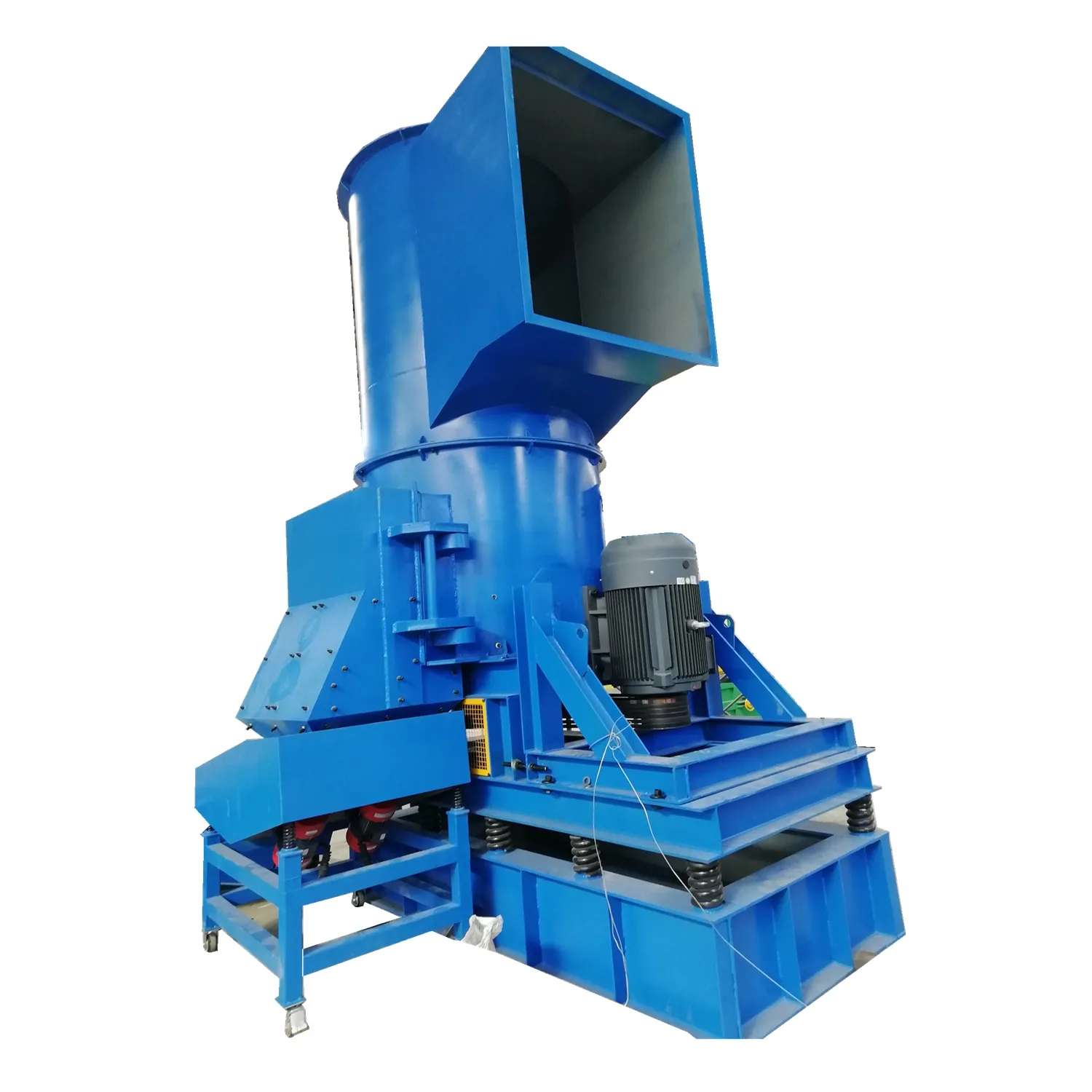

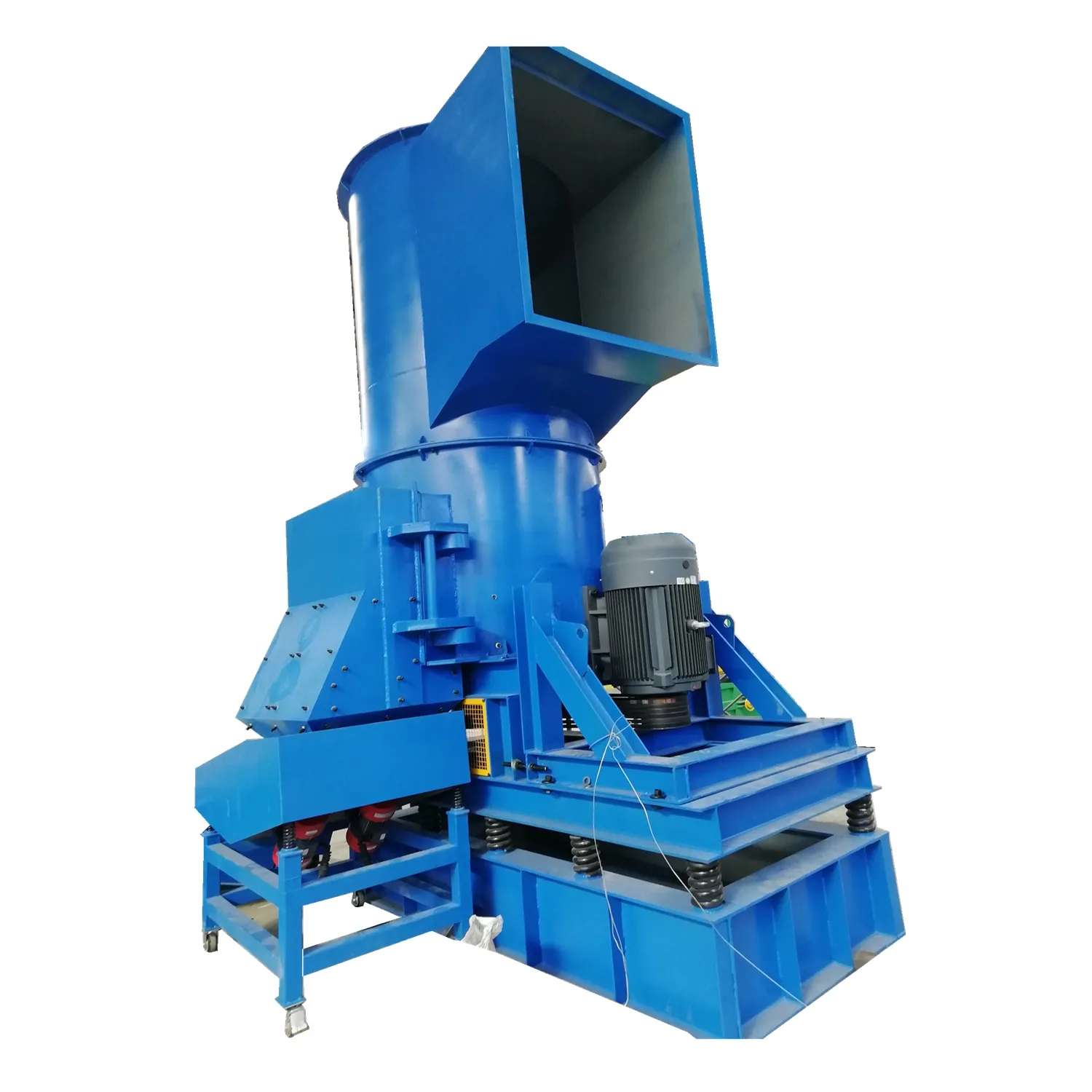

Once PCBs arrive at the facility, they undergo a series of manual and automated separation processes. Initially, workers remove any easily detachable components such as batteries or casings. These initial phases set the stage for the more complex processes that follow, where specialized machinery is employed to shred and pulverize the PCBs into smaller fragments.

Technical Processes and Expertise

The subsequent stage harnesses cutting-edge technology to extract valuable metals from the board fragments. Pyrometallurgical and hydrometallurgical techniques are commonly employed. Pyrometallurgy involves high-temperature processing that can effectively separate metals without the use of chemicals. This method is often favored for its speed and efficiency but requires significant energy consumption.

On the other hand, hydrometallurgy offers a more environmentally-friendly alternative by using aqueous chemistry to recover metals. This process often involves leaching agents that dissolve specific metals, allowing for their selective extraction. Professionals in this field possess a deep understanding of chemical reactions and the ability to handle potentially dangerous substances with precision.

how to recycle pcb

To maximize metal recovery while minimizing environmental impact, a combination of both methods is sometimes employed. Each type of PCB may require a unique recycling procedure, thus underscoring the need for both technical knowledge and practical experience.

Building Trust Through Transparency

Trust is a cornerstone of effective recycling operations. Companies must maintain rigorous documentation of their methodologies and processes to assure stakeholders of their commitment to safety and sustainability. Certification from reputable bodies such as the R2 (Responsible Recycling) and e-Stewards standards can greatly enhance credibility and trustworthiness in the industry.

Moreover, fostering partnerships with tech manufacturers and collaborating on product design can lead to the creation of more recyclable devices in the future. Sharing data and insights gleaned from recycling processes not only aids manufacturers but also helps consumers understand the importance of responsible e-waste disposal.

Collaborative Efforts for Sustainable Future

Recycling PCBs is not just a technical challenge but a societal one.

It demands the collaboration of recycling experts, manufacturers, consumers, and policymakers. Educational outreach and public awareness campaigns are crucial in highlighting the importance of recycling and encouraging responsible consumer behavior.

Furthermore, investing in research and development can pave the way for innovative recycling technologies that are both cost-effective and environmentally benign. As new materials and manufacturing techniques emerge, continuous adaptation and learning from past experiences will be key to improving recycling efficiency.

In conclusion, the recycling of PCBs is a sophisticated process requiring a harmonized approach blending expertise and technology with transparency and collaboration. By embracing these principles, we not only reclaim valuable resources but also safeguard our planet for future generations.