Recycling printed circuit boards (PCBs) has become a crucial aspect of modern electronic waste management. As technology advances, the proliferation of electronic devices means an ever-increasing accumulation of e-waste. The PCB, a vital component in nearly every electronic device, holds not only valuable metals but also hazardous materials that need careful handling. Understanding how to recycle PCBs effectively can significantly contribute to environmental conservation and resource recovery.

The process of recycling PCBs is both intricate and specialized, requiring expertise to extract precious metals like gold, silver, copper, and palladium, which are embedded in the board. These metals can be reused in manufacturing new products, reducing the need for virgin raw materials.

Experience in the field shows that successful PCB recycling begins with the collection phase. Accumulating used electronics from various sources—such as households, businesses, and institutions—is the first step. It's essential to have a structured collection system, often facilitated by local governments or private recycling companies, to gather a sufficient quantity of PCBs.

Once collected, the next phase is the dismantling process, where electronic devices are carefully disassembled to retrieve the PCBs. This phase requires expertise and trained personnel to ensure that the boards are not damaged, which could result in a loss of recoverable materials.

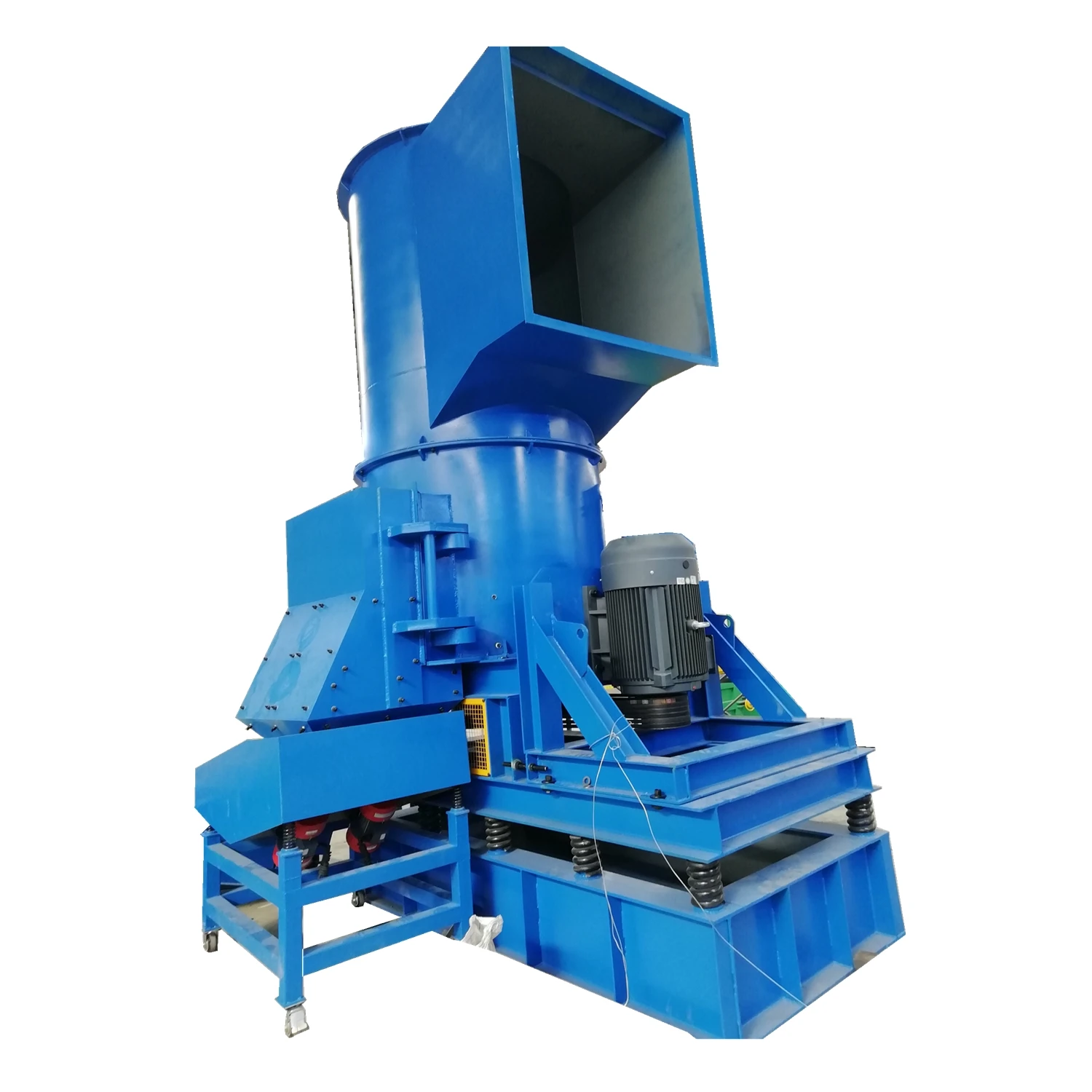

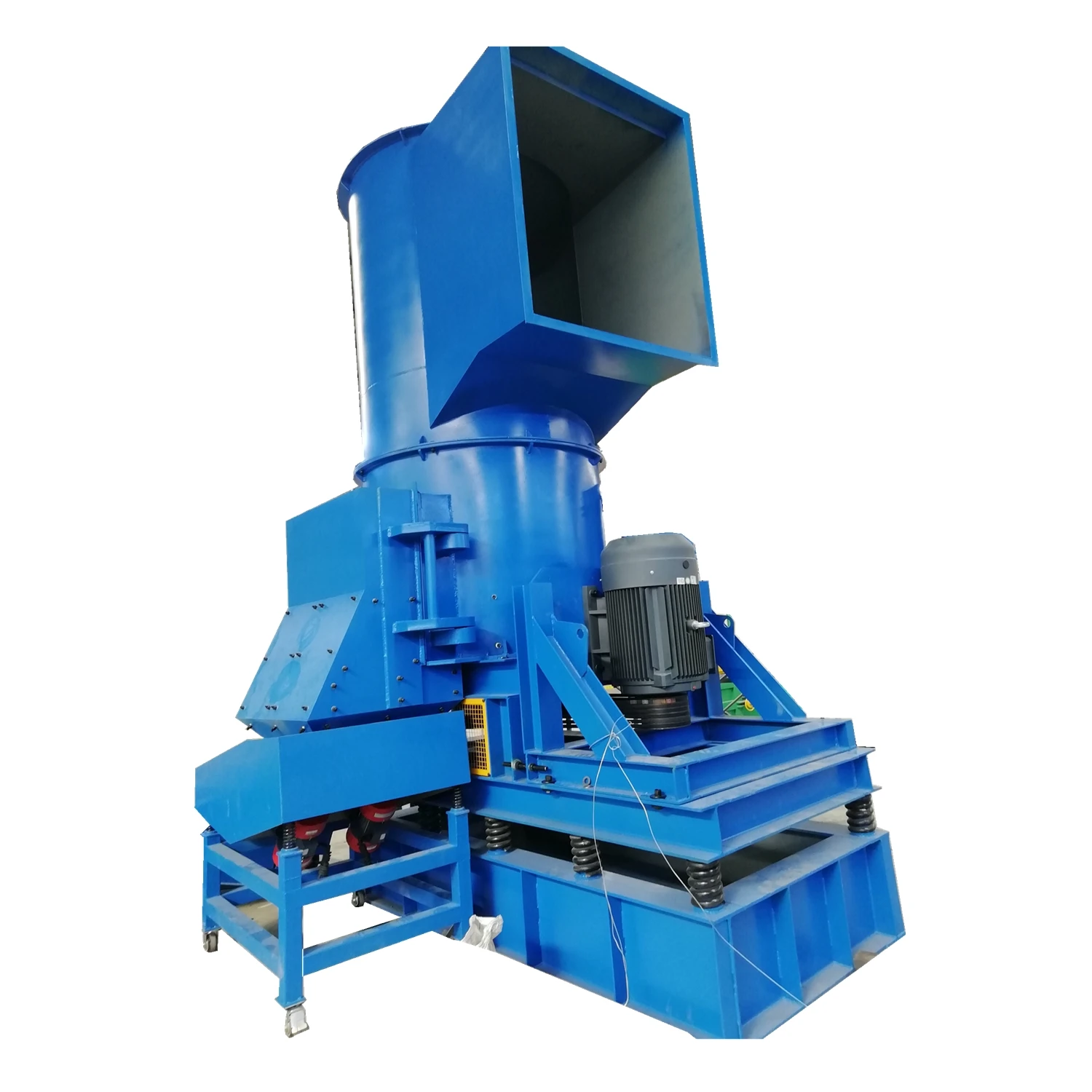

Following dismantling, PCBs undergo a series of mechanical and chemical processes to separate the metals from the non-metal fractions. Initially, shredding the boards into smaller pieces makes further processing more manageable. This is followed by physical separation techniques such as air classification and magnetic separation, which isolate metallic elements.

how to recycle pcb

Chemical processing is a critical stage in PCB recycling, where various methods are employed to recover metals. Hydrometallurgical methods, for example, involve using chemical reactions in aqueous solutions to extract metals. This technique is advantageous due to its high recovery rates and relatively lower environmental impact compared to traditional methods.

Moreover, expertise in pyro-metallurgical methods can be beneficial in certain scenarios. This involves high-temperature treatments to smelt metals from the boards. Although energy-intensive, pyro-metallurgical processes can be highly efficient in metal recovery when executed correctly.

Authoritativeness in PCB recycling is achieved by staying abreast of technological advancements and strictly adhering to environmental regulations. Recycling facilities must comply with stringent laws to prevent environmental contamination and ensure worker safety. Accreditation from relevant authorities and independent audits are pivotal in establishing a facility’s credibility and trustworthiness.

Trustworthiness in this industry is built through transparent operations and engaging in responsible practices. Recycling companies should provide clear documentation of their processes and demonstrate a commitment to minimizing environmental impact. Partnering with certified recycling companies can ensure that PCBs are handled properly, thus preventing illegal dumping or unsafe recycling practices.

In conclusion, as electronics continue to evolve, effective PCB recycling presents both a challenge and an opportunity. Experience, expertise, authoritativeness, and trustworthiness serve as cornerstones in developing efficient recycling systems. By prioritizing these elements, we can ensure that the recycling of PCBs not only preserves valuable resources but also protects our environment for future generations.