Granulators play a pivotal role in various industries, from recycling to pharmaceuticals. Their primary function is to reduce materials into smaller, uniform granules, a crucial process for efficient production and waste management. Understanding how a granulator works provides invaluable insights for businesses looking to optimize their manufacturing or recycling processes.

Granulators typically consist of several key components a feed hopper, rotor blades, stationary knives, and a screen. Each element contributes to the granulator's overall functionality, ensuring materials are processed accurately and efficiently.

The process begins with raw materials fed through the hopper. These materials can range from plastics and rubber to food products and pharmaceuticals. The choice of granulator depends significantly on the nature of the material being processed and the desired output size.

Once materials enter the hopper, they come into contact with the rotor—a cylindrical component equipped with multiple cutting blades. As the rotor spins, these blades slice through the material with precision. This cutting action, driven by the motor, is critical for reducing the material into smaller, manageable pieces.

Accompanying the rotor blades are stationary knives, strategically positioned within the granulator. These knives work in unison with the moving rotor blades, ensuring that materials are sheared effectively. The combination of rotor and stationary knives creates a scissor-like action, maximizing cutting efficiency while minimizing energy consumption.

how does a granulator work

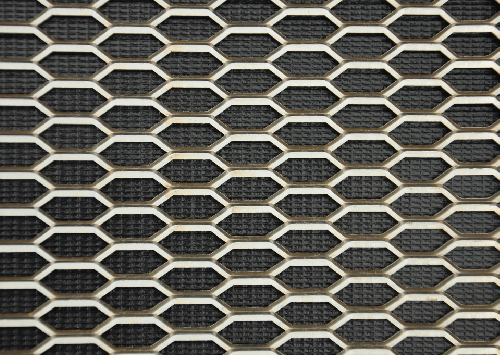

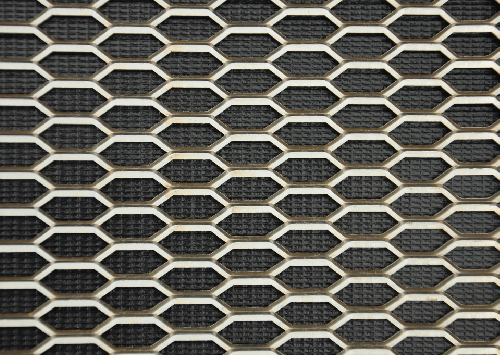

One of the defining features of a granulator is its screen, located beneath the rotor and blades. This screen contains numerous perforations, allowing only materials reduced to the appropriate size to pass through. The size of the perforations determines the granule size, making the screen an essential component for achieving the desired consistency.

Granulators offer unique advantages that enhance their efficiency. Many modern granulators come equipped with soundproofing features to minimize noise during operation—a crucial consideration in industrial and laboratory settings. Additionally, they are designed with easy maintenance in mind, featuring accessible components that simplify cleaning and reduce downtime.

Safety remains a top priority when operating granulators. Modern granulators incorporate various safety mechanisms, such as emergency stop buttons and automatic shutdown features, to prevent accidents and ensure the well-being of operators. Proper training and adherence to safety protocols further enhance operational safety.

Understanding the intricacies of how granulators function not only aids in selecting the right equipment but also enables businesses to optimize their processes, leading to increased productivity and reduced waste. By producing uniform granules, companies can ensure consistent product quality, streamline downstream operations, and improve the economics of recycling processes.

In summary, granulators are instrumental in transforming bulk materials into finer, uniform granules through a precise cutting mechanism involving rotor blades, stationary knives, and a screen. Their application spans various industries, making them indispensable tools for improving operational efficiency and product quality. With advancements in technology and design, granulators continue to evolve, offering even greater levels of efficiency, safety, and ease of maintenance, thereby reinforcing their position as essential machinery in modern industrial and production environments.