Copper wire granulators play a pivotal role in recycling, acting as essential machinery in the transformation of waste copper wire into valuable raw material. Understanding how these machines operate not only enriches one's appreciation of the recycling process but also underscores their significance in sustainable resource management.

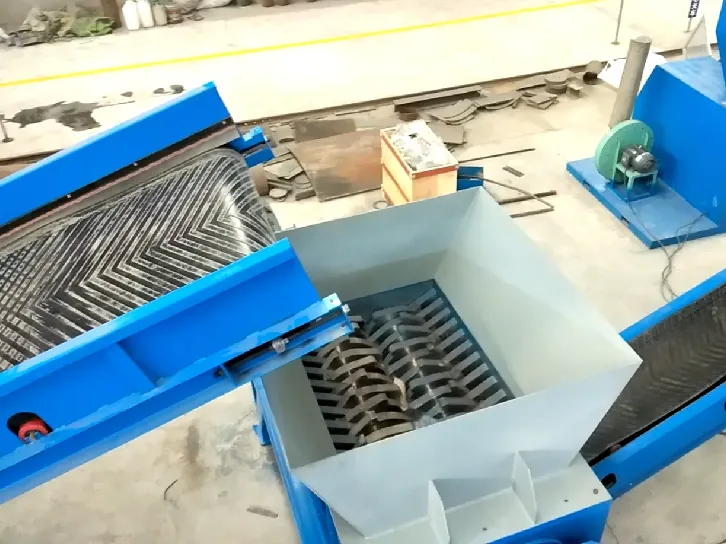

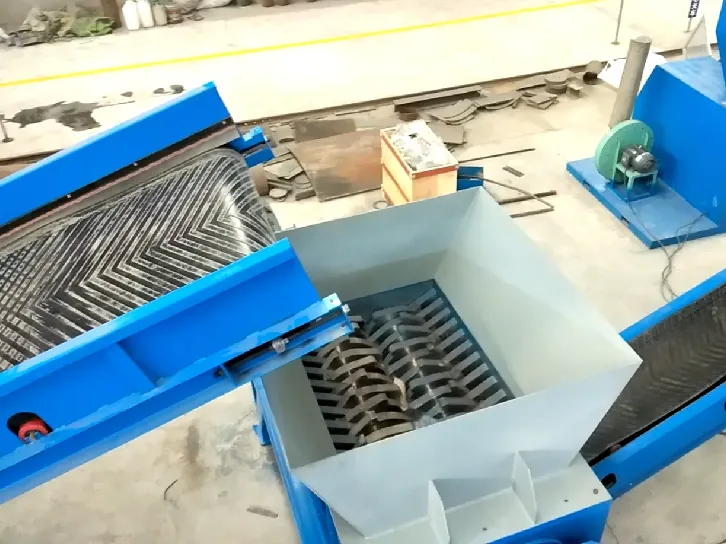

A copper wire granulator works by using a combination of mechanical and air separation techniques to extract copper from insulated wire and cable. The process begins when bulk loads of wire are fed into the granulator’s hopper. Once inside, the wires are directed towards a cutting chamber equipped with high-speed rotating blades. These blades are crucial for shredding the wire into smaller, manageable fragments.

The granulation phase is precise, designed to reduce the wire to granules, which facilitates the subsequent separation of the metal from its insulator. The granulated material then moves to a pulverizer, where further grinding occurs.

This produces a mixture of copper particles and plastic insulation. It's a testament to the machine's engineering prowess that it can process a variety of cables and wires, each differing in size and insulation type, without compromising efficiency.

Following granulation and pulverization, the material is conveyed to an air separator. This component operates under the principle of density differentiation—copper, being denser than plastic, can be effectively isolated. As air pushes the lighter plastic particles away, the heavier copper granules settle into a separate collection area. This stage is crucial, as it ensures that the purest form of copper is obtained, enhancing its resale value and usability.

Operational expertise with copper wire granulators requires an understanding of both the machinery and the materials being processed. For instance, operators must be familiar with different types of wires and cables, each of which may require distinct operational settings for optimal processing efficiency. The knowledge of how to adjust the blade speed and air flow can significantly enhance the separation precision, leading to higher quality output.

how does a copper wire granulator work

Furthermore, consistent maintenance of the granulator is indispensable, with routine checks and procedures minimizing downtime and extending the machine's lifecycle. The blades, being the most active component, require regular sharpening or replacement. Lubrication of moving parts and timely updates to control systems also bolster performance reliability.

Professionals in the recycling industry widely regard copper wire granulators as an authoritative solution to wire waste problems. Their ability to return copper to a reusable form without degrading its quality lends these machines a trusted reputation for sustainability. They embody a commitment to resource efficiency, offering a profitable means to reduce both environmental impact and raw material costs.

Finally, when considering the investment in a copper wire granulator, potential buyers are encouraged to assess the credibility of manufacturers. Trustworthy manufacturers not only provide robust machinery but also offer comprehensive support services, including training, troubleshooting, and parts replacement. This reliability ensures that businesses can maintain a steady recycling workflow, ultimately reinforcing their commitment to eco-friendly practices.

In conclusion, understanding the workings of a copper wire granulator illuminates its integral role in effective recycling strategies. By converting waste into wealth, these machines not only address environmental concerns but also enhance business viability in a resource-conscious world. As copper continues to be an essential material across industries, investing in granulation technology reflects both environmental stewardship and economic foresight.