The journey of creating a homemade copper wire granulator is not just about constructing a machine; it's about harnessing your expertise and passion for sustainable practices and efficient recycling. Homemade copper wire granulators offer a cost-effective way to recycle copper from scrap wires, making them a valuable addition for anyone involved in electrical work or recycling industries.

Creating an effective copper wire granulator at home requires a deep understanding of both the intricacies of machine building and the science of materials recycling. The first step in this process is selecting the right materials. Opt for high-quality steel for the granulator's frame and blades, as this ensures durability and longevity. Pairing strong materials with precise engineering will result in a granulator that can handle various wire thicknesses effectively.

Understanding the mechanics is crucial. A copper wire granulator typically consists of a feed system, a cutting system, and a separation system. The effectiveness of the machine largely hinges on the cutting and separation units. In a homemade setup, precision in crafting the blades for the cutting system can make a significant difference. Industrial machines use strong and sharp blades that cut through plastics and copper effortlessly. Emulating this through careful sharpening and material choice can improve performance significantly.

Crafting the separation system calls for expertise in material density.

The objective is to separate the copper from the plastic insulation efficiently. One method to consider is using airflow separation. This method leverages differences in material density for separation. Well-tuned fans and blowers can help achieve cleaner separation, increasing the value of the recovered copper.

Transitioning from concept to execution, it's important to integrate safety and efficiency in your design. Operate with a clear understanding of the electrical systems. Incorporating failsafe mechanisms, such as emergency stop buttons and protective casings over moving parts, enhances safety.

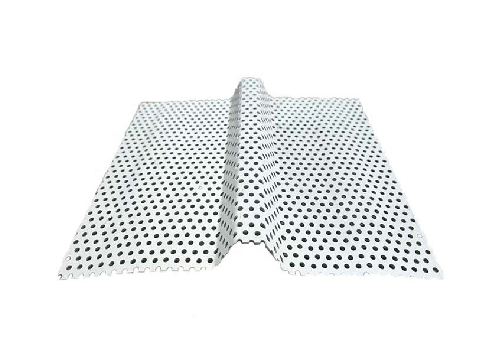

homemade copper wire granulator

Programming expertise is also beneficial when constructing a more advanced version of this granulator. Implementing sensors and automated controls can streamline the operation process, making your homemade copper wire granulator more user-friendly and efficient. The use of sensors to detect jammed wires or irregular feed rates helps in maintaining a smooth operation and protects the machine from potential damage.

Building a homemade copper wire granulator is not only an exploration in engineering and recycling; it's a commitment to sustainability and eco-friendly practices. By recycling copper wire, you contribute to the reduction of environmental footprint caused by raw material mining and waste. It's a project that underscores the importance of expertise and trustworthiness in creating dependable systems that are environmentally responsible.

For those looking to share their knowledge and invoke positive environmental change, documenting the construction process through articles, videos, or workshops can establish authority. Engage with online communities or recycling forums to exchange insights and improve your design. Such interactions help build a trustworthy reputation and position you as a subject matter expert within the DIY recycling community.

An effective homemade copper wire granulator does more than just separate materials; it represents a fusion of technical prowess and environmental advocacy. It's a testament to using innovation not only for personal benefit but for fostering an eco-conscious approach to resource management. Through this project, the expertise and trustworthiness demonstrated can inspire countless others to venture into similar sustainable endeavors, multiplying the positive impact on our global ecosystem.