Heavy metal shredders have become indispensable in a variety of industries, serving a crucial role in recycling processes by transforming bulky metal waste into valuable resources. Navigating the world of metal shredders can be complex, but understanding their function, benefits, and the latest technological advancements can set you on the right path toward optimizing your metal processing needs.

At the heart of any metal recycling operation, heavy metal shredders significantly improve efficiency by reducing the volume of metal waste. These powerful machines operate through a series of blades or hammers designed to break down large metal pieces into smaller, more manageable sizes. The shredded output can easily be sorted, melted, or repurposed into new products, which is vital for the sustainability initiatives that many industries now embrace.

One of the primary reasons heavy metal shredders stand out is through their robust design and capacity to handle various metals — from aluminum and copper to more resilient materials like steel and iron.

This versatility is a testament to the shredder's engineering prowess. Compact designs allow for installations in tighter spaces, while larger industrial models can process several tons of metal an hour, showcasing their adaptability to different scale operations.

A key advantage that bolsters the widespread use of heavy metal shredders is their efficiency, both in terms of energy consumption and performance. Shredders equipped with energy-efficient motors not only cut down on electricity costs but also contribute to reducing the overall carbon footprint of the recycling process. This aspect is particularly appealing to companies aligning their methodologies with environmental regulations and corporate social responsibility goals.

Safety is a paramount concern when dealing with heavy machinery, and the latest shredders come laden with features that enhance operational security. Automated systems are now more common, minimizing human interaction with the machinery during the shredding process, thus reducing the risk of accidents. Innovations such as advanced sensor technology can quickly detect anomalies or jams within the shredder, automatically halting operations to allow for safe inspection and maintenance.

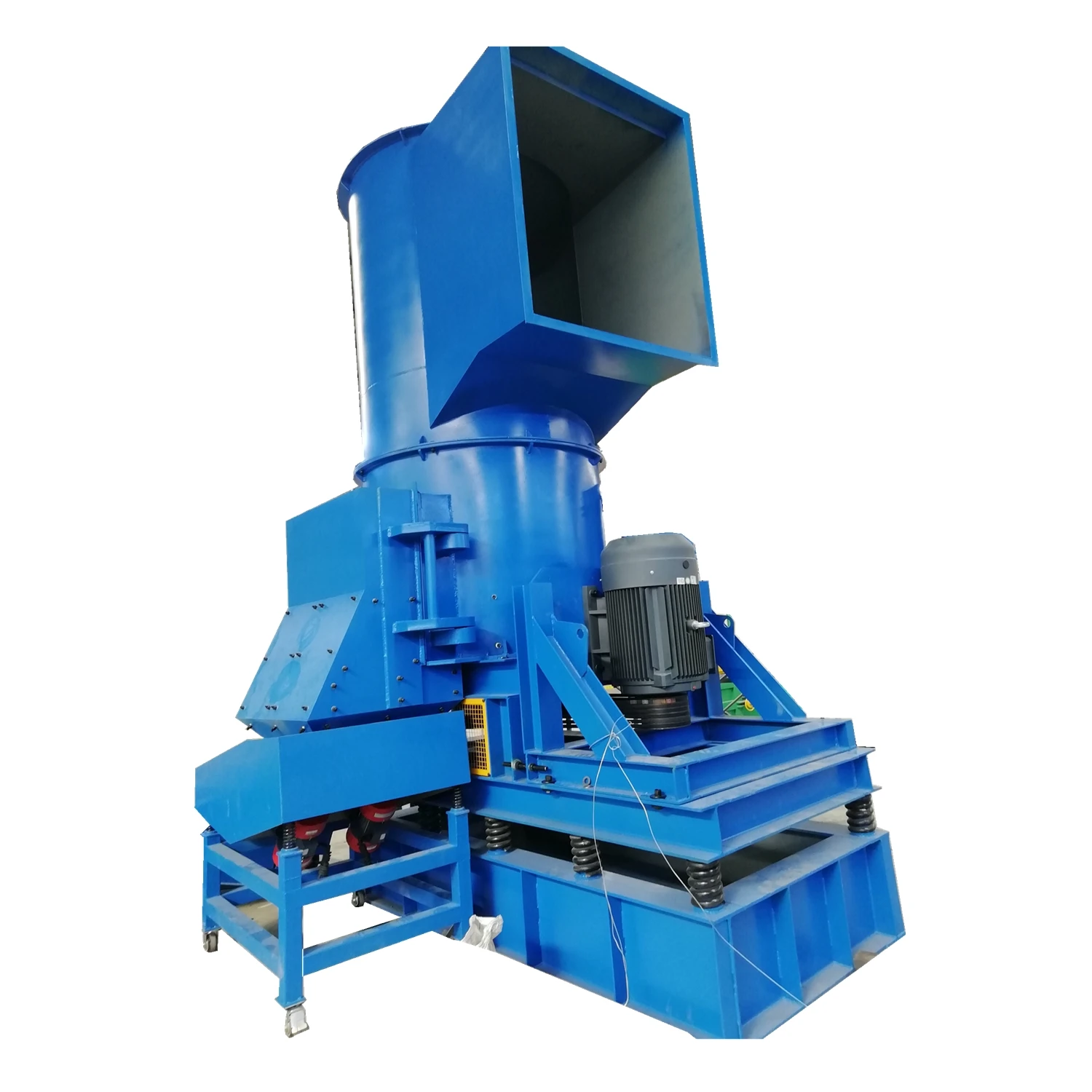

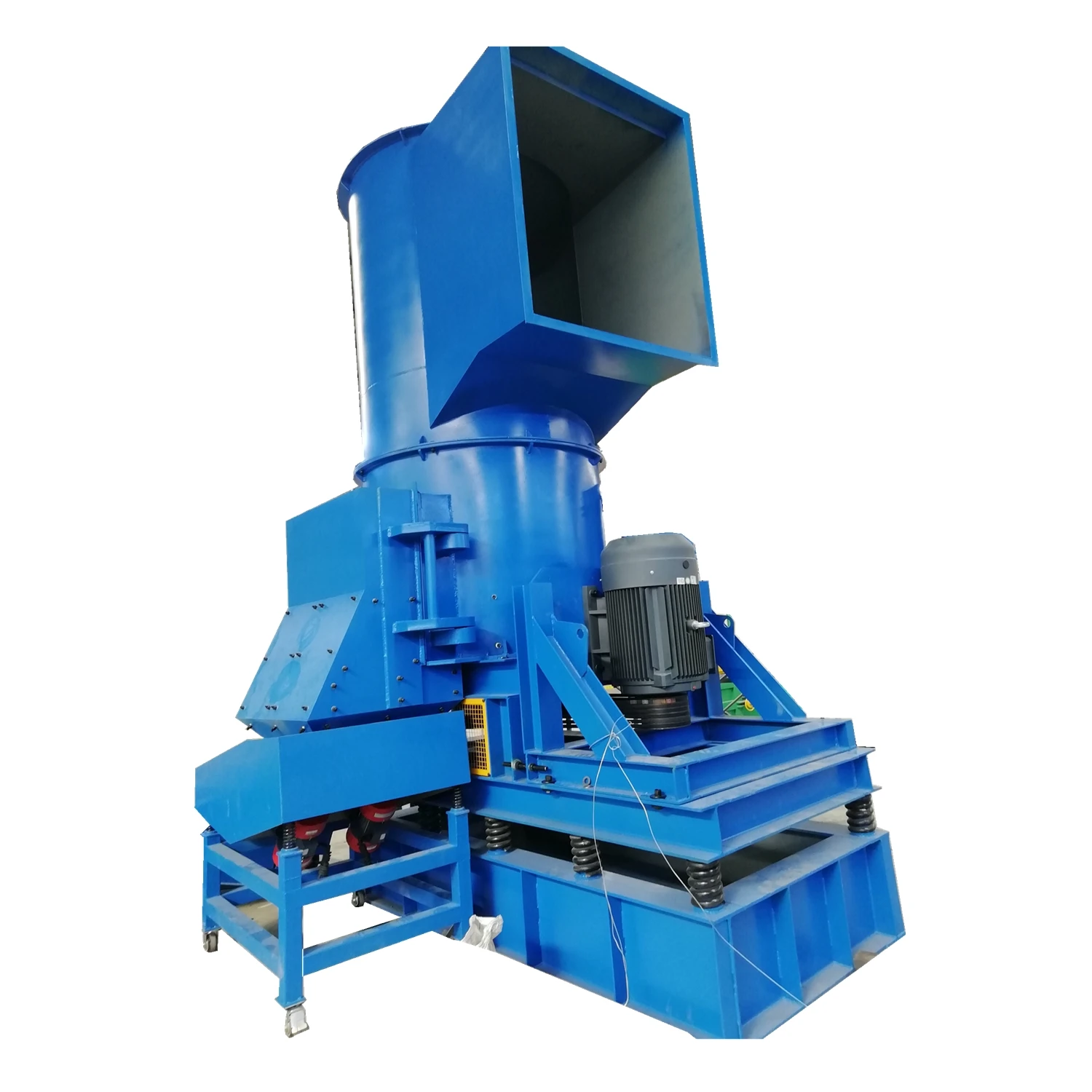

heavy metal shredder

Shredder manufacturers are continually innovating, integrating the latest technology to enhance usability and maintenance. For instance, many modern shredders feature interactive digital displays offering real-time data about the machine's status, summarized performance metrics, and predictive maintenance alerts. Such features streamline the upkeep process, ensuring that the shredder operates at peak efficiency with minimal downtime.

Investing in a heavy metal shredder involves a significant upfront cost, and understanding the potential return on investment is crucial for businesses. Apart from direct financial gains linked to metal recycling rebates and reduced waste disposal costs, shredders contribute to long-term savings compared to other methods of waste management. When selecting a shredder, it's critical to weigh factors such as processing capacity, machine durability, and after-sales support from manufacturers to ensure sustained performance over time.

Moreover, the credibility of shredders as pivotal tools in the circular economy reinforces their significance. By facilitating the recycling of metals, these machines help industries cut down on raw material consumption while decreasing environmental impact. This plays a substantial role in fostering a sustainable future and underscores their value in advancing industrial ecological practices.

When selecting a heavy metal shredder, engaging with industry experts and consulting detailed reviews can offer insights into the model that best fits your specific needs. Custom-designed shredders are also an option for businesses handling unique materials or operating under specialized conditions, providing a tailored solution to recycling challenges.

In conclusion, heavy metal shredders are not just powerful machines; they embody the future of sustainable metal management. By enabling efficient recycling, reducing ecological footprints, and enhancing safety and innovation, these machines empower industries to advance toward more eco-friendly and cost-effective solutions. As technology continues to evolve, investing in heavy metal shredders remains a forward-thinking choice for businesses looking to optimize their resources and contribute to global sustainability efforts.