For industries reliant on crushing equipment, selecting the right hammer for crushers is pivotal to ensuring operational efficiency and longevity. From mining to construction, the hammer plays a crucial role in breaking down material into manageable sizes. Making the right choice involves understanding both the mechanical and material aspects of the hammer, and how they intersect with the equipment and specific applications.

One of the most important considerations is material composition. Hammers are generally made from wear-resistant materials such as manganese steel, martensitic steel, or high chromium alloys. Each material has distinct attributes that make it suitable for particular applications. Manganese steel, for example, is renowned for its toughness and ability to work-harden. This makes it ideal for applications involving high impact but low abrasion conditions. Conversely, high chromium alloys offer excellent wear resistance, making them suitable in environments where material abrasiveness is a concern.

Proper hammer geometry is another critical factor. The shape and thickness can significantly impact the crushing process and hammer lifespan. A hammer’s shape can affect how material is fed and crushed, influencing both efficiency and wear distribution. Thicker hammers can handle higher impact forces and are suitable for primary crushing, whereas thinner hammers are often employed for secondary crushing where material size is smaller.

Balancing the hardness and toughness of the hammer is key to its performance. A hammer that is too hard could be brittle and prone to cracking or breaking under heavy impact. On the other hand, if it is too tough, it might wear quickly and lose efficiency. Therefore, achieving the right balance through appropriate heat treatment processes is critical. Optimal thermal processing can enhance the hammer’s hardness while maintaining its toughness, leading to improved durability and performance.

Installation and maintenance practices greatly influence hammer lifespan. Correct installation ensures that the hammers are balanced and aligned, reducing unnecessary wear and tear. During operation, regular maintenance checks should be conducted to assess wear levels and prevent unexpected failures. Monitoring techniques such as vibrational analysis and infrared inspections can help foresee potential issues and schedule timely maintenance.

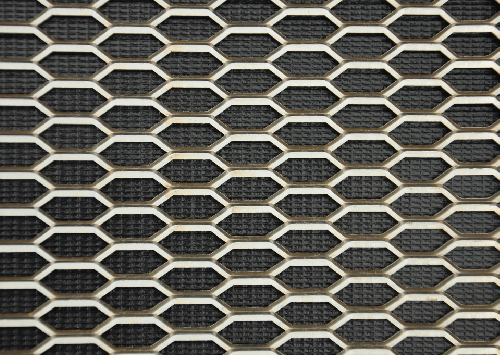

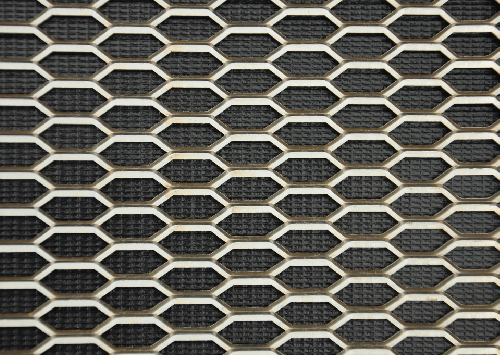

hammer for crusher

Another aspect that affects a hammer’s efficiency is the crusher’s design and operation. The crusher must be configured to optimize the hammer’s performance, which means considering factors such as feed size, rotor speed, and crushing cavity design. A mismatch between hammer specifications and crusher settings can lead to suboptimal performance and increased wear.

From a sustainability standpoint, the choice of hammer can also influence environmental impact. Durable, long-lasting hammers not only result in reduced operational costs but also minimize waste and reduce the need for frequent replacements. Ensuring that worn hammers are recycled can contribute to sustainable practices within the industry.

Expertise in material sciences and engineering is essential when selecting the appropriate hammer for a crusher. Consulting with manufacturers and leveraging their technical resources can provide deeper insights into the best material composites and designs for specific applications. Tailored advice from experts allows for fine-tuning hammer specifications to match the requirements of both the machine and the raw material being processed.

Trust in the supplier is another key factor. A reputable supplier not only offers high-quality products but also provides support and technical guidance. Verifying the supplier’s credentials, client testimonials, and after-sales service can enhance confidence in the hammer’s quality and performance.

In conclusion, the hammer for crusher is a multi-faceted component whose impact on efficiency, durability, and cost-effectiveness cannot be overstated. By meticulously considering material composition, geometric design, performance balance, installation practices, and supplier reliability, industries can enhance their operational reliability and reduce overall expenses. The intersection of experience, expertise, authoritativeness, and trustworthiness is paramount for making educated choices that align with both immediate needs and long-term strategic goals.