With the increasing demand for efficient and reliable coal processing, choosing the right equipment is crucial for industries involved in coal mining and processing. Among the various types of coal crushers available, the hammer coal crusher emerges as an optimal solution. This article delves into the unique benefits and technical aspects of hammer coal crushers, underscoring why they are favored over other crusher types.

Hammer coal crushers are known for their robust construction and high crushing efficiency. These machines operate on a simple yet effective principle using high-speed rotating hammers to crush the coal fed into the machine. This method not only ensures thorough size reduction but also minimizes the generation of dust—a common problem in coal processing. The simplicity of this mechanism allows for easy operation, even with minimal technical training, amplifying its usability across various industrial applications.

Constructed from high-quality materials like steel alloys, hammer coal crushers offer unparalleled durability. This robust build ensures that the crushers can withstand the rigors of continuous heavy-duty operations. Moreover, the hammers, which play a crucial role in the crushing process, are replaceable and made from wear-resistant materials, ensuring lengthy operational life and reducing downtime and maintenance costs. This feature not only extends the lifespan of the equipment but also enhances the overall cost-effectiveness of the coal processing operation.

From an expertise viewpoint, the design of a hammer coal crusher incorporates advancements that cater to varying industrial needs. These crushers can be configured to cater to different coal processing requirements, such as varying the gap size between the hammers and the screens to achieve the desired coal size output. This flexibility makes them particularly useful in industries where output size can significantly influence the quality and utility of the processed coal.

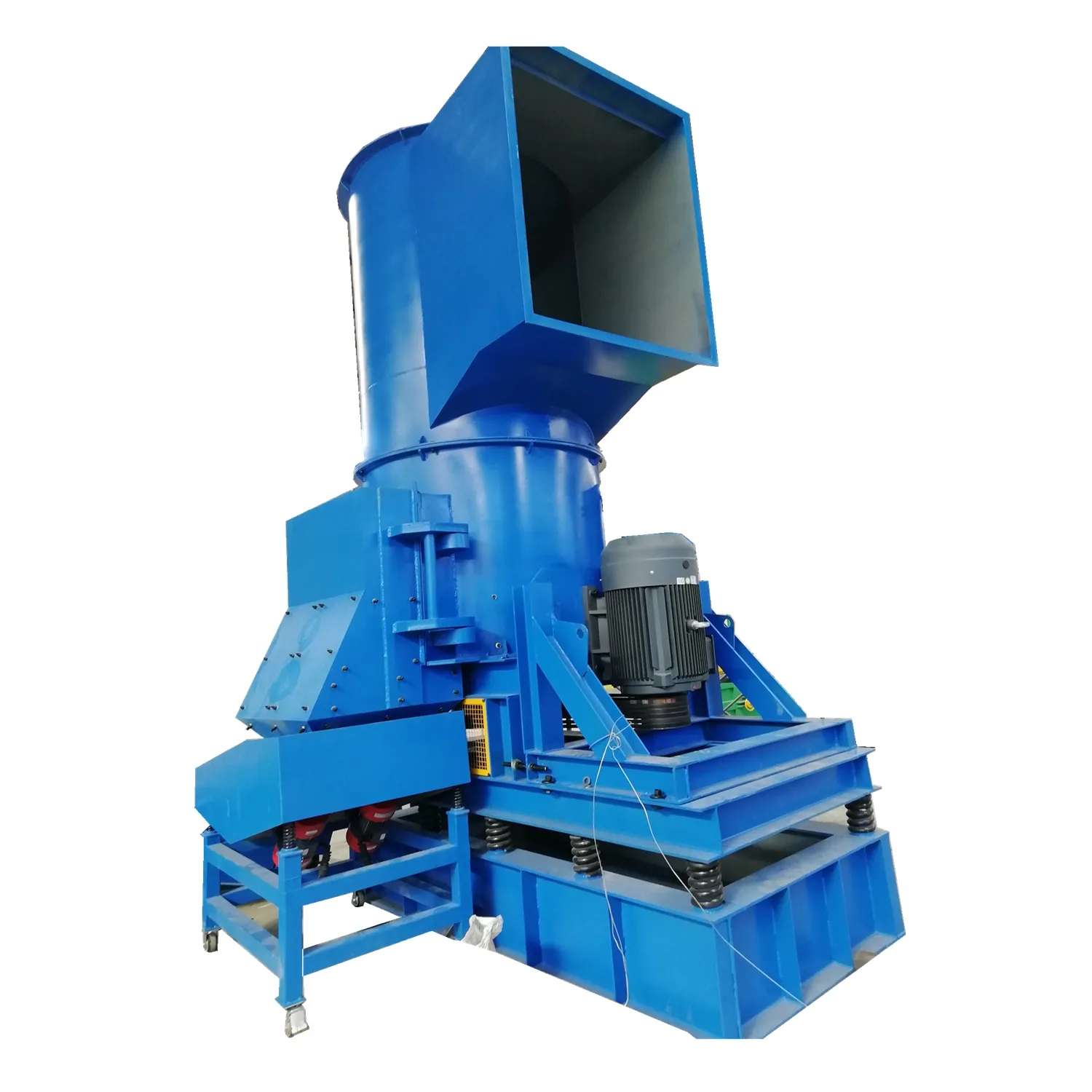

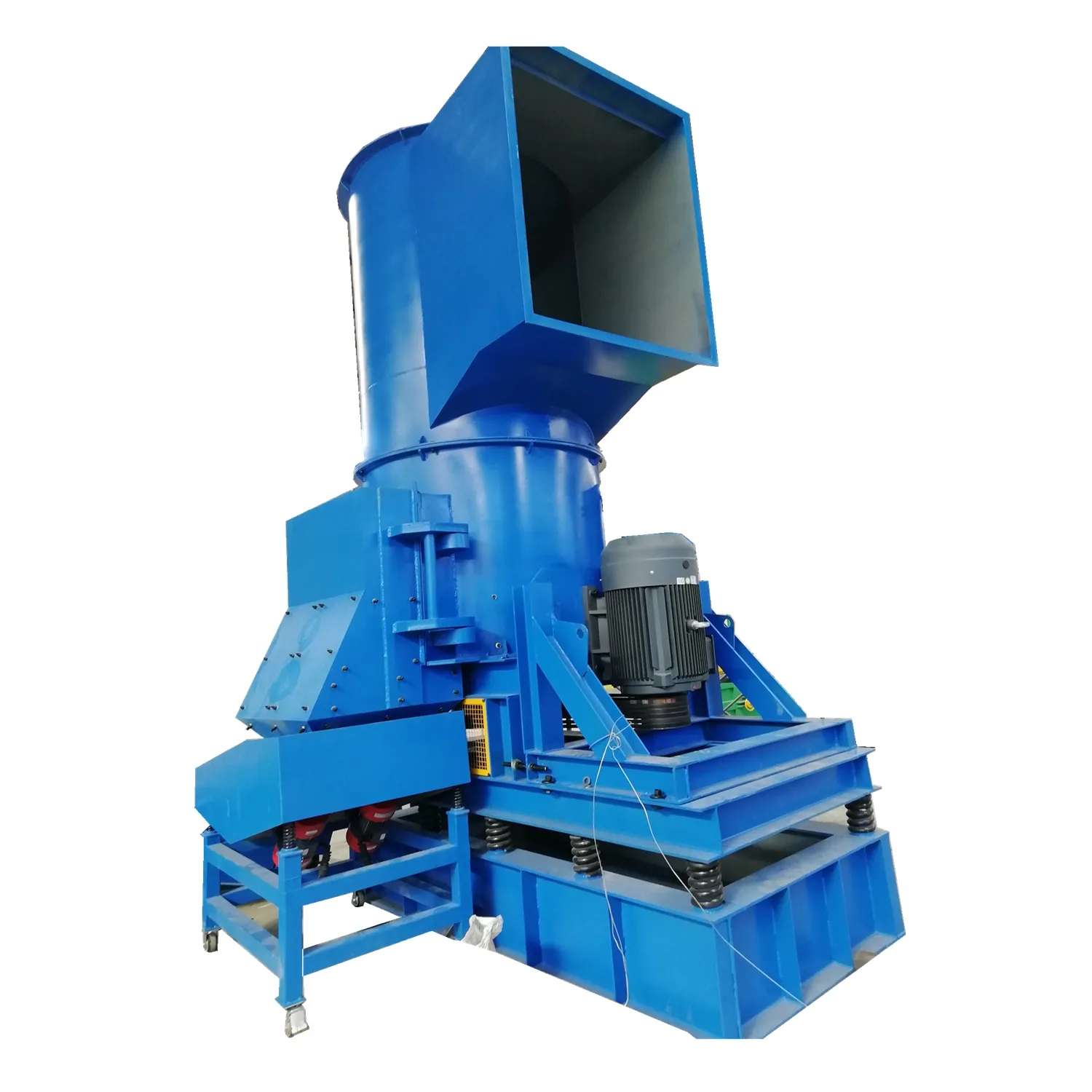

hammer coal crusher

When assessing the authoritativeness of hammer coal crushers, industry endorsements and widespread utilization serve as strong indicators. Notably, these crushers are trusted by leading coal processing companies around the globe for both their efficiency and reliability. Their integration into coal processing plants results in higher productivity levels and improved quality of the end product, reinforcing their reputational solidity in the market.

Trustworthiness in hammer coal crushers is attributed to the use of modern manufacturing techniques and adherence to international safety and quality standards. Reputable manufacturers ensure that each unit undergoes rigorous testing before distribution, a practice that guarantees machines not only meet but often exceed customer expectations. The after-sales support provided by these manufacturers, including timely maintenance services and availability of spare parts, further enhances their reliability.

In terms of practical experience, many users report significant improvements in crushing efficiency and operational cost savings after transitioning to hammer coal crushers from other types. The ability of these crushers to handle large volumes of coal and produce a consistent output size has proven instrumental in optimizing the overall efficiency of coal processing plants. Additionally, their straightforward design translates to easier diagnostic and repair processes, minimizing the technical barrier for operation and maintenance staff.

The adoption of hammer coal crushers is influenced by a confluence of factors, encompassing operational efficiency, cost-effectiveness, and reliable performance. As industries continue to prioritize these attributes in their equipment selection process, hammer coal crushers secure their position as invaluable assets in coal processing operations. By investing in these crushers, companies can achieve enhanced productivity, reduced operational costs, and improved product quality, aligning with their long-term strategic goals in a competitive market landscape.