Guidetti granulators have revolutionized the recycling industry with their impeccable design and efficient performance. As one of the leading pieces of equipment in the granulation market, Guidetti granulators are known for converging expertise, engineering prowess, and reliability in a single package. This article explores the advantages these granulators bring to industries and why they stand as a testament to best practices in recycling innovation.

Guidetti granulators are a product of meticulous engineering tailored to meet the diverse needs of modern recycling processes. Their designs are based on an extensive understanding of material behaviors under stress and shear, enabling the granulators to reduce a wide array of materials such as cables, plastics, and metals into uniform particles. This capability is crucial in the recycling industry where the consistency of particle size can significantly impact the efficiency of recycling processes.

The usability of Guidetti granulators spans industries including electronics, automotive, construction, and packaging. For instance, in electronics recycling, these granulators play a pivotal role in the recovery of valuable metals from circuit boards, ensuring minimal wastage and maximum yield. Their compact size and efficiency make them ideal for operations where workspace and energy consumption are constraints.

One of the core aspects of Guidetti granulators is their commitment to sustainability and operational efficiency. Built with the latest technology, these machines minimize energy consumption through innovative motor designs that optimize both speed and torque. This not only reduces the operational costs for users but also aligns with global efforts to promote environmentally responsible manufacturing practices.

Field experts highlight the exceptional durability and low maintenance requirements of Guidetti granulators, emphasizing their long-term reliability. The use of high-quality materials and precision engineering ensures that these machines can withstand intensive use without frequent breakdowns, thereby instilling a sense of trust and dependability among users. Regular feedback from industry practitioners reveals a pattern of extended operational lifespans, reinforcing the notion of a low total cost of ownership.

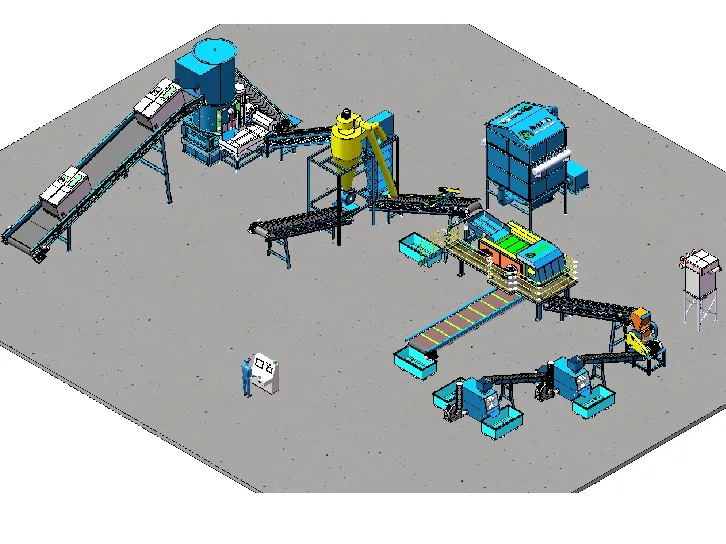

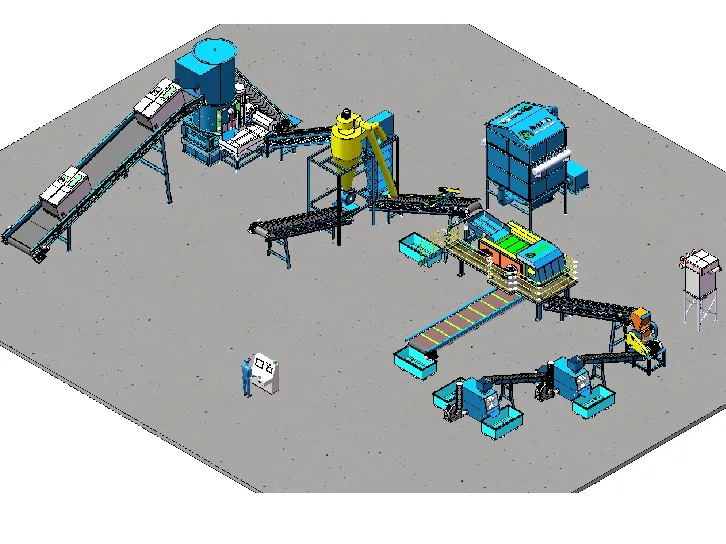

guidetti granulator

The expertise ingrained in Guidetti granulators is not only a result of technical design but also due to their adaptive approach to user interaction. These granulators feature intuitive control systems that streamline operations, allowing operators of varying skill levels to manage and adjust settings efficiently. This user-centric approach reduces training time and errors, maximizing productivity.

Moreover, Guidetti's authoritative stance in the market is backed by regular advancements and updates in their product line. The brand continuously invests in research and development, ensuring that their equipment remains at the forefront of technological advancements. Certifications from leading industry bodies and compliance with international safety and quality standards further solidify its authoritative position.

Each Guidetti granulator is accompanied by robust customer support, offering guidance and solutions tailored to specific recycling challenges. This support network is pivotal in establishing trust with their clientele, providing reassurance that expert assistance is always at hand.

In conclusion, Guidetti granulators exemplify a harmonious blend of experience, expertise, authoritativeness, and trustworthiness. Their impact on the recycling industry is profound, offering reliable, efficient, and sustainable solutions. For businesses looking for top-tier granulation equipment, Guidetti undoubtedly represents a benchmark of quality and performance excellence.