Enhancing efficiency and recycling capability, ferrous shredders play a crucial role in the metal recycling industry. Through expertise in this specialized field, it becomes clear how these powerful machines transform scrap metal into valuable resources, advancing both environmental sustainability and economic viability.

At the heart of a ferrous shredder's operation lies its robust design. These industrial machines are engineered to handle a diverse range of ferrous materials, including scrap iron and steel. Equipped with reinforced alloy steel blades, they pulverize large metal items into smaller, manageable pieces. This process not only prepares the materials for further processing but also ensures the removal of contaminants. The expertise of engineers and designers shines through in the shredders’ ability to process even the toughest of metals efficiently while maintaining durability and operational integrity over prolonged periods.

Expertise in the field showcases that the efficiency of ferrous shredders is dramatically influenced by features such as motor power, throughput capacity, and size reduction ratio. High motor power enables the machine to process large volumes of ferrous scrap swiftly, while the throughput capacity dictates how much material can pass through the shredder at a given time.

Professionals in metal recycling understand that choosing the right shredder means balancing these attributes to match specific operational needs. Consequently, selecting a shredder with the appropriate power and capacity can significantly increase productivity and profitability in recycling operations.

Trustworthiness in using ferrous shredders also involves understanding the critical safety protocols that ensure both operator safety and machine longevity. Manufacturers and industry experts continuously strive to incorporate the latest safety mechanisms, such as emergency shutoff systems and anti-jam software. Operators receive specialized training to handle these machines adeptly, minimizing the risk of accidents and maximizing operational efficiency.

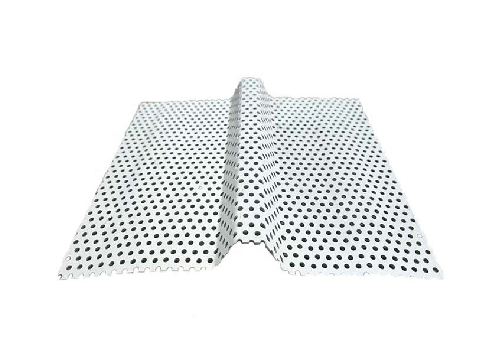

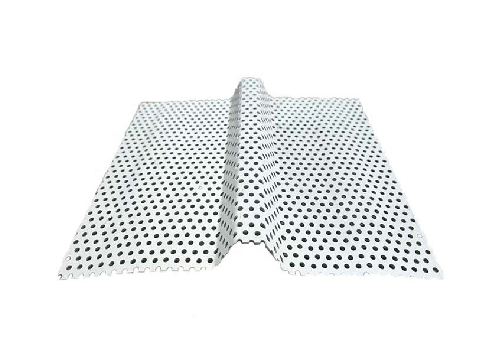

ferrous shredder

Moreover, the authority of ferrous shredders in recycling economics is unmistakable. As global demand for recycled metals increases, these machines are pivotal in meeting those requirements. Ferrous shredders not only lower the costs associated with transporting and storing bulky scrap metal but also improve the quality of end products by ensuring a consistent feedstock size and purity level. This improvement leads to higher market prices for recycled materials and better returns on investments for recycling companies.

The experience of seasoned operators adds depth to the operational knowledge of ferrous shredders. They can adjust settings to accommodate different materials, increasing the flexibility and versatility of the shredding process. Their hands-on experiences foster innovation in designing workflow processes that optimize machine use, reduce wear and tear, and extend the maintenance cycles. This expertise contributes significantly to the machine’s reliability and efficiency, which in turn reinforces the trust stakeholders place in the shredding processes.

In conclusion, ferrous shredders embody a synergy of engineering excellence and operational expertise that propels the metal recycling industry. By leveraging advanced technology, ensuring stringent safety standards, and applying practical experiences, these machines stand as a testament to sustainable industrial practices. They not only enhance the recycling process but also play a significant role in environmental conservation, making them indispensable assets in the race towards a circular economy. Amidst ever-growing environmental challenges, ferrous shredders remain an authoritative and trustworthy solution for responsible recycling and resource management.