Eddy current waste separation technology has fundamentally transformed the recycling industry, providing an efficient and effective solution for separating non-ferrous metals from waste streams. This technology harnesses the principles of electromagnetism to strategically sort metals without the need for manual intervention, thus significantly increasing recycling productivity and purity.

The experience of employing eddy current waste separators in waste management facilities is overwhelmingly positive. Operators appreciate the technology's ability to drastically reduce the time required to process mixed waste materials. In facilities where tons of recyclable materials are sorted daily, the efficiency improvement is substantial. By eliminating the need for manual sorting, facilities can allocate human resources to other critical tasks, reducing labor costs substantially over time.

From a technical perspective, eddy current separators are sophisticated pieces of machinery. They consist of a conveyor belt system paired with a rotor that creates a powerful magnetic field. When non-ferrous metals, such as aluminum and copper, pass through this magnetic field, eddy currents are induced within them. These eddy currents generate opposing magnetic fields, effectively repelling the metals from the rest of the waste stream. This technical setup not only ensures a high rate of separation efficiency but also guarantees minimal operational downtime, as the robust design minimizes maintenance requirements.

The expertise surrounding eddy current separation technology is notable. Manufacturers have developed these systems with advanced sensor technology that can be customized to adjust based on specific waste stream compositions. This adaptability is crucial for facilities dealing with varying input materials, ensuring maximum recovery of non-ferrous metals. Further expertise is demonstrated in the continuous evolution of rotor design and materials used, aiming to push the boundaries of speed and efficiency while keeping energy consumption in check.

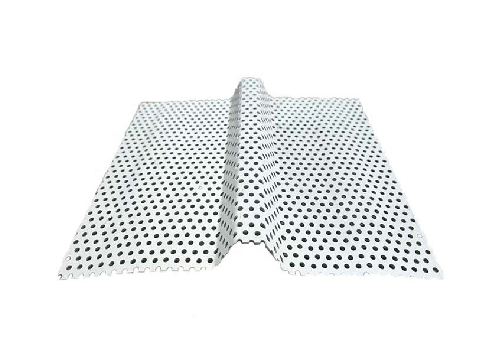

eddy current waste separation

The authoritative voice in this domain echoes the importance of integrating eddy current separators within comprehensive recycling processes. Research indicates that the inclusion of eddy current separation can improve the overall recycling rates of facilities by up to 30%. This is coupled with higher purity levels of recovered metals, which fetch better prices in the commodities market, enhancing the economic viability of recycling initiatives. The authority of this technology is reinforced through numerous case studies and reports from reputable industry bodies that advocate for its adoption as a standard practice in modern waste management.

Trustworthiness is an inherent quality of eddy current waste separation technology, backed by decades of reliable performance across global facilities. The technology is proven, with numerous installations worldwide attesting to its durability and efficiency in extreme operating conditions. Moreover, manufacturers of eddy current separators are often members of major recycling and environmental associations, adhering to stringent guidelines and standards that ensure the reliability and safety of their equipment. Users can trust that these systems not only deliver promised performance but also contribute positively toward sustainable waste management goals.

As recycling becomes an increasingly critical component of environmental sustainability, the role of eddy current separators continues to grow. They represent a pinnacle of engineering achievement in the recycling sector, a testament to human ingenuity in addressing ecological challenges. For companies looking to optimize their recycling operations, investing in eddy current waste separation technology is not just an option but a strategic move towards a cleaner, more resource-efficient future. The technology is indispensable for anyone serious about making substantial contributions to resource conservation and waste reduction, solidifying its position as a cornerstone of modern waste processing strategies.