Eddy current sorting machines have redefined the landscape of material recovery facilities, earning a reputation as indispensable tools for increasing efficiency and achieving more sustainable processing operations. This technological advancement excels in separating non-ferrous metals from waste streams, providing industries with an innovative solution to enhance their recycling processes.

In an era where sustainability and resource efficiency dictate industrial trends, businesses are actively seeking methods to improve their recovery rates of valuable materials.

Eddy current sorting machines utilize a simple yet highly effective electromagnetic process. The principle revolves around eddy currents induced in conductive materials by a rapidly changing magnetic field. When non-ferrous metals like aluminum, copper, and brass pass through an alternating magnetic field, they experience repulsion and are separated from other materials. This ensures an efficient and continual sorting process without manual intervention.

These machines boast several distinct advantages, placing them at the forefront of recycling solutions. First and foremost, their operational efficiency is unmatched. With the ability to sort materials at incredibly high speeds, they drastically reduce manual labor costs while simultaneously minimizing error rates. The machines can process large volumes of materials, which is crucial for facilities handling vast amounts of waste. Operators find that the intuitive design and automated processes require less frequent adjustments and maintenance, resulting in lower long-term operational costs.

Moreover, eddy current sorting machines exhibit remarkable accuracy. The precision with which they separate materials ensures that the recovery of valuable non-ferrous metals is maximized. Facilities employing this technology report significant improvements in the quality and purity of their sorted materials, which fetch higher market prices and ensure better profitability. Additionally, they enhance the overall quality of sorted waste streams, streamlining the downstream processes such as smelting or further refinement.

The incorporation of eddy current sorting machines offers tangible environmental benefits as well. By optimizing the recovery of non-ferrous metals, industries can substantially reduce their dependency on virgin materials, thus conserving natural resources. Furthermore, the recycling processes fostered by these machines considerably diminish the need for energy-intensive mining operations, consequently lowering the carbon footprint associated with material production.

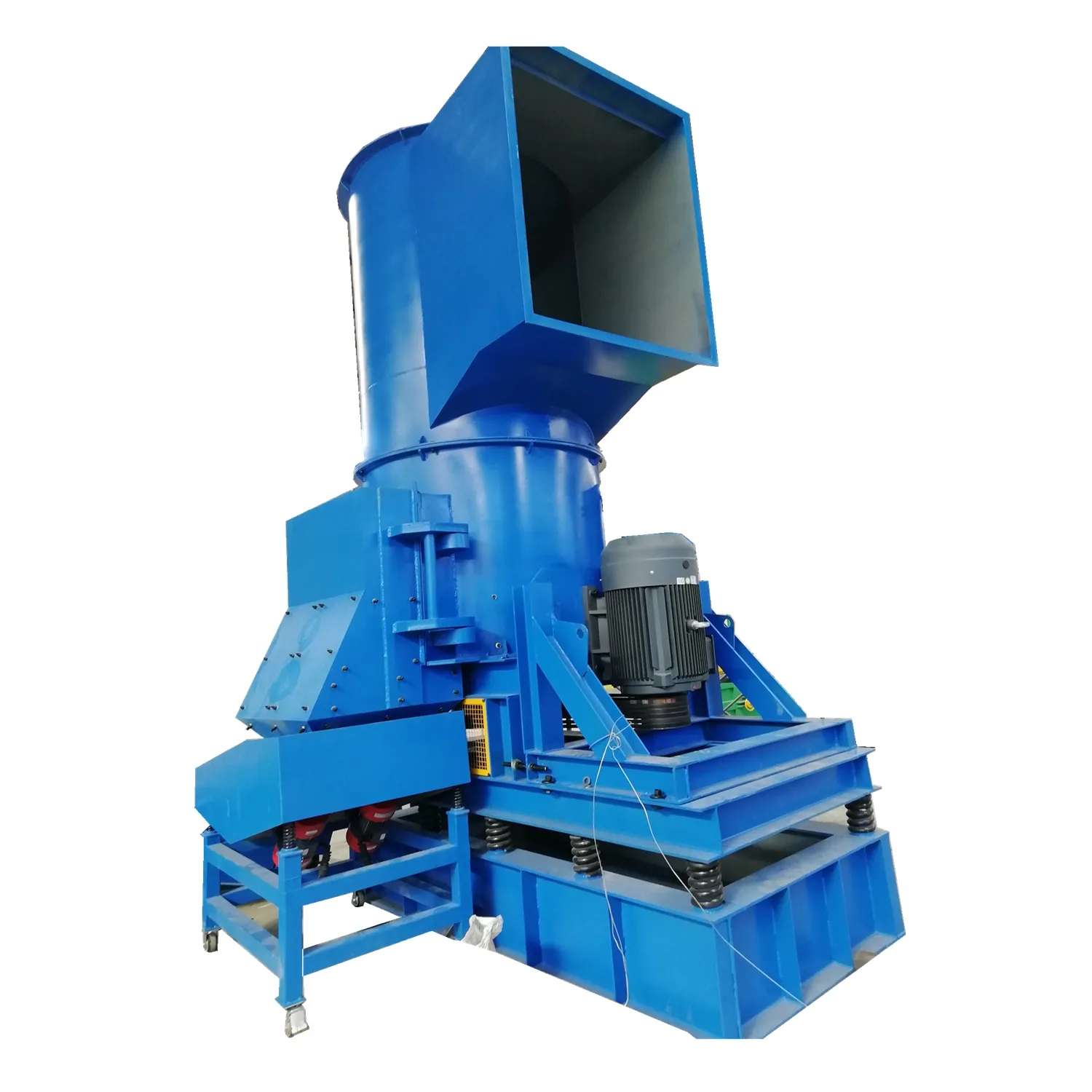

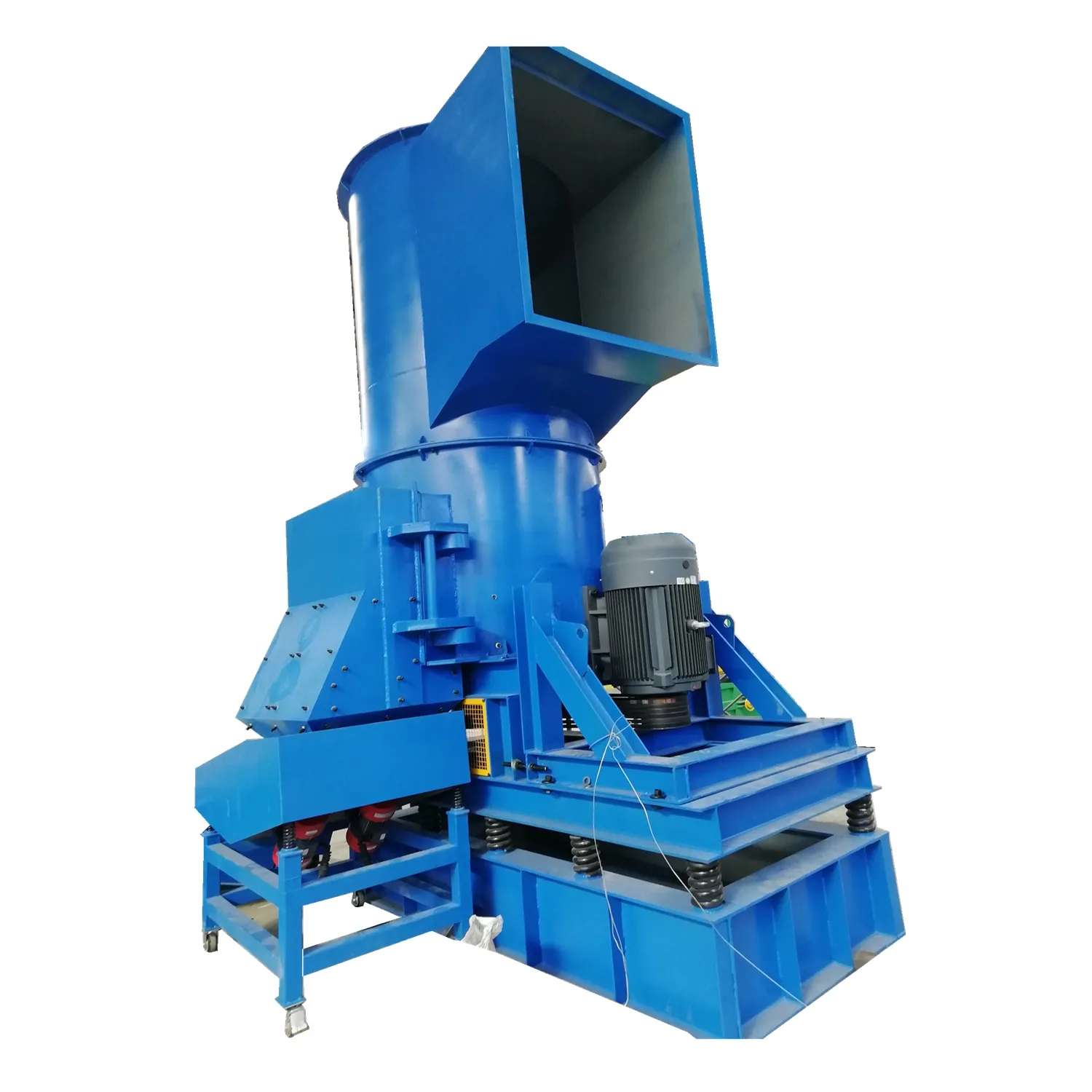

eddy current sorting machine

Industries utilizing eddy current sorting machines experience an enhanced reputation in line with contemporary corporate social responsibility (CSR) standards. Companies that prioritize sustainability practices stand out to consumers and shareholders, who increasingly value eco-conscious operations. By investing in advanced sorting technology, businesses not only boost their financial performance but also gain a competitive edge in an environmentally-conscious market.

From an operational standpoint, the adaptability of eddy current sorting machines cannot be overstated. These machines can be integrated seamlessly into existing recycling sorting lines, requiring minimal restructuring of current systems. Their versatility allows for the processing of a diverse range of materials, catering to industries ranging from automotive to electrical waste recycling. This adaptability ensures that facilities can respond to varying waste streams and market demands efficiently.

Further emphasizing the technological prowess of these machines, many models come equipped with sophisticated control systems and real-time monitoring tools. These features empower operators with valuable data and insights, enabling them to make informed decisions and fine-tune processes on-the-fly. As machine learning and AI technologies continue to evolve, the integration of these elements into eddy current sorting machines is on the horizon, promising even greater efficiency and autonomy.

Despite the clear advantages, the initial investment for eddy current sorting machines can be significant. However, facilities soon realize substantial cost savings through improved sorting efficiency and purity, reduced labor, and lower maintenance demands. The return on investment can be quick, especially for high-volume operations where the reduction in resource waste and enhancement of material value are markedly evident.

The ever-evolving landscape of recycling technology consistently challenges industries to adopt newer solutions. Eddy current sorting machines epitomize the perfect blend of efficiency, precision, and environmental stewardship that modern facilities aim to achieve. As industries face growing pressure to implement sustainable practices, these machines offer an unparalleled opportunity to meet and exceed contemporary standards, merging technological innovation with essential environmental responsibility.