When it comes to finding the best eddy current separator manufacturers, a comprehensive understanding of the product and the companies driving innovation in this field is essential. Eddy current separators are critical in various industries, such as recycling, waste management, and mining, due to their efficiency in metal separation from non-metallic materials. This article examines key players in the industry, highlighting their unique capabilities, expertise, and contributions to technology advancements.

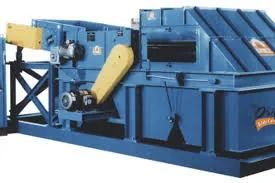

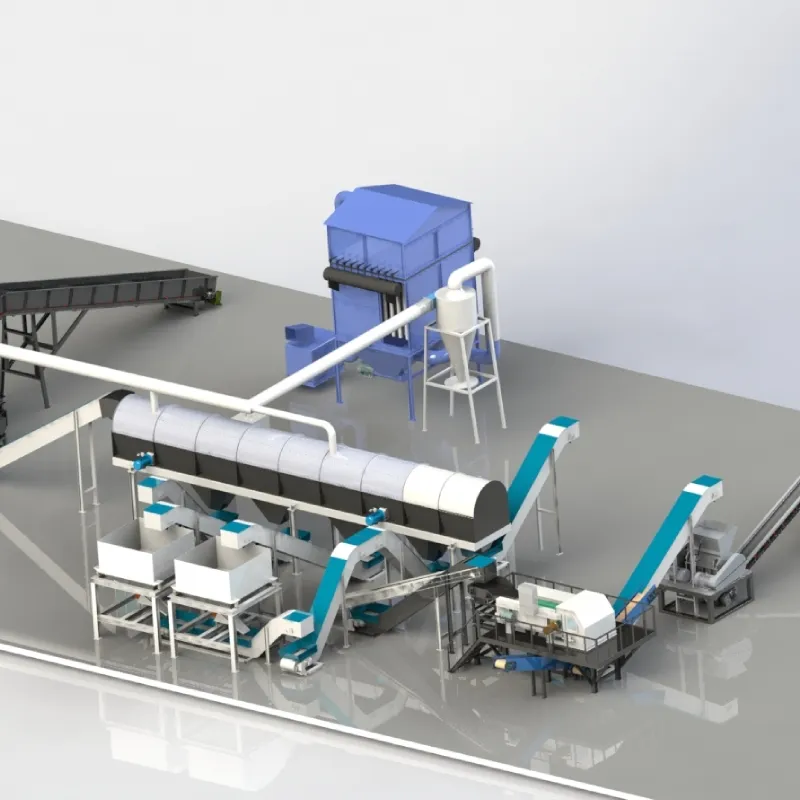

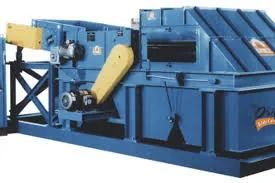

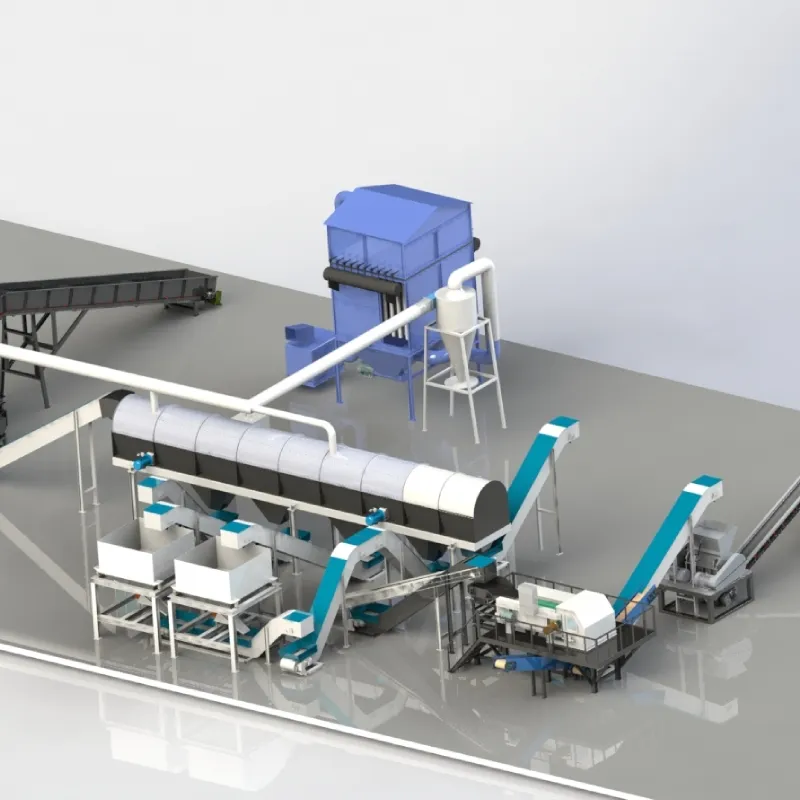

The eddy current separator operates on the principle of magnetic induction to separate non-ferrous metals from mixed material streams. This advanced engineering feat relies on a rotating drum coupled with powerful magnets to induce eddy currents in conductive particles. These induced currents generate opposing magnetic fields, repelling non-ferrous metals from the non-metallic material stream.

There are several manufacturers that have established themselves as authorities in the field. Companies like Eriez, Steinert, and Bunting are prominent due to their innovative approaches, extensive experience, and robust product lines that cater to a variety of industrial needs.

Eriez, a global leader, has consistently demonstrated its expertise through continuous research and development efforts. Their eddy current separators are known for their high precision and efficiency even in the most challenging conditions. Eriez has designed systems that accommodate varied capacities, ensuring tailored solutions for industries ranging from large-scale waste processing plants to specialized recycling facilities.

Steinert, another key player, exemplifies reliability with over a century of experience. Known for their cutting-edge technology, Steinert's eddy current separators integrate seamlessly into existing setups while offering maximum separation efficiency and durability. Their separators are renowned for their ability to recover high-value materials, promising quick return on investment for their clients.

eddy current separator manufacturers

Bunting is synonymous with trustworthiness in material handling. Their robust product lineup is characterized by durability and high-performance standards. Bunting offers personalized consultation services to adapt their separators to specific operational needs, ensuring client satisfaction. They emphasize environmentally responsible practices, providing solutions that minimize ecological impact, aligning with the increasing global emphasis on sustainability.

Beyond individual capabilities, these companies contribute significantly to advancing eddy current separator technology. They invest heavily in engineering advancements, pushing the boundaries of what these machines can achieve. Developments such as improved magnetic strength, enhanced sorting precision, and reduced energy consumption are a testament to their commitment to industry progress.

Selecting the right manufacturer depends on specific criteria, including application requirements, operational scale, and budgetary constraints. An ideal manufacturer not only offers top-tier products but also provides exceptional after-sales support, including maintenance, training, and installation services. This holistic customer service approach fosters long-term partnerships and ensures operational continuity for clients.

In conclusion, the landscape of eddy current separator manufacturers is defined by a few key players who continuously innovate to meet industrial demands. With their deep expertise, commitment to technological advancement, and dedication to sustainable practices, companies like Eriez, Steinert, and Bunting lead the charge in providing top-of-the-line separation solutions. Their reputations for expertise and trustworthiness make them the go-to options for industries seeking reliable and efficient metal separation technologies. Investing in their technology ensures not only operational efficiency but also contributes to sustainable industrial practices.