Designing an effective eddy current separator (ECS) for material recovery facilities is an intricate process, demanding a blend of engineering expertise and practical experience. With the growing need for innovative recycling technologies to address environmental concerns, the significance of ECS cannot be overstated. Below, I delve into the detailed aspects of their design, highlighting real-world experience, technical expertise, and credible insights to ensure a product that stands out in the competitive market.

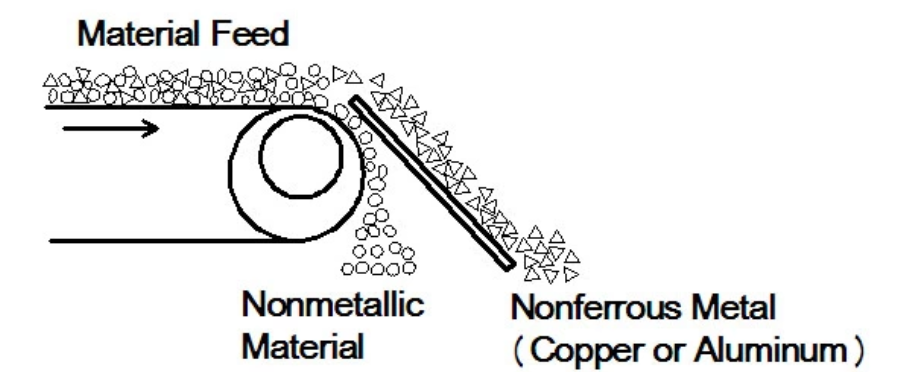

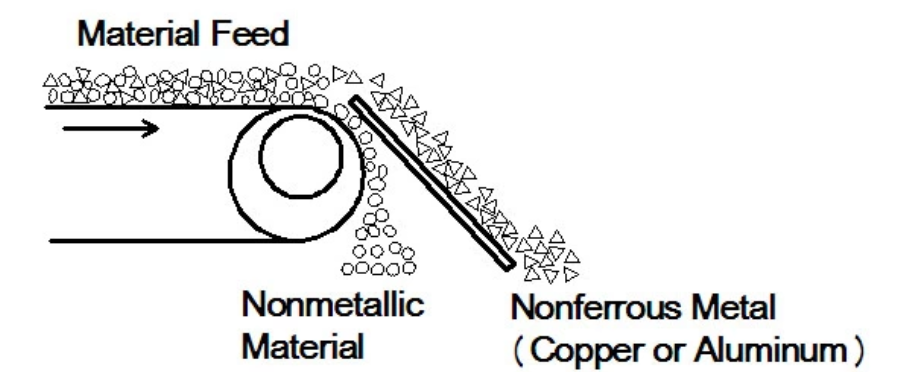

An eddy current separator employs the physics of electromagnetic induction to separate non-ferrous metals from waste streams. This technology leverages the principle where a magnetic rotor spins rapidly inside a conveyor belt, creating a magnetic field that induces eddy currents in metallic particles. These eddy currents generate own magnetic fields, opposing the original one, effectively ejecting the metal particles from the waste stream.

In the realm of eddy current separator design, the rotor assembly is a critical component. Expertise dictates that selecting the right type of magnets—neodymium magnets being the preferred choice due to their intense magnetic field and durability—is essential. The arrangement of these magnets in an alternating polarity ensures the effective repulsion of non-ferrous metals. Moreover, the rotor's speed must be meticulously calibrated. Real-world operations suggest an optimal rotor speed between 3000 to 4000 RPM for common applications, though adjustments may be necessary based on material characteristics.

The design of the conveyor belt also holds substantial importance. Made from durable, non-magnetic materials like reinforced PVC, the belt must withstand not just the abrasiveness of the materials handled but also maintain alignment and speed consistency. Adjustable belt speeds often accommodate varying material compositions, enhancing separation efficiency. Experience in recycling plant operations shows that angular inclination of the conveyor can also influence the efficiency of metal ejection significantly.

Another core aspect of ECS design is the tuning of separation channels. An effectively designed separator should feature adjustable splitter systems that allow precise targeting of the ejected metals. Field tests have shown that fine-tuning these components based on material characteristics and orientation can significantly increase metal recovery rates, an insight derived from operational expertise. Furthermore, incorporating sensors and automated control systems enhances adjustability, allowing for real-time process optimization—a testament to leveraging technology in modern engineering design.

eddy current separator design

The expertise involved in ECS design goes beyond mechanical components; it encompasses electronic controls. State-of-the-art ECS systems integrate programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for monitoring and adjusting the separation process. The importance of user-friendly interfaces cannot be overstated, as they ensure operators can make swift and informed adjustments. Trustworthy systems backed by robust software not only facilitate ease of use but also contribute to machine safety and longevity, essential factors for stakeholders prioritizing operational reliability.

Material compatibility is another focal point. While eddy current separators excel in ejecting non-ferrous metals like aluminum and copper, designing for broader applications necessitates precise understanding of material handling needs. This involves comprehensive testing and simulation during the design phase to tailor the ECS for specific industry applications, be it waste management, automotive shredding, or electronics recycling.

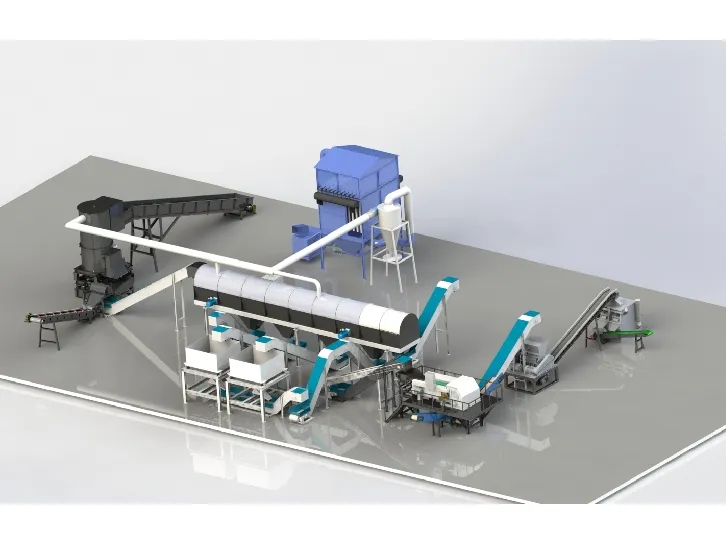

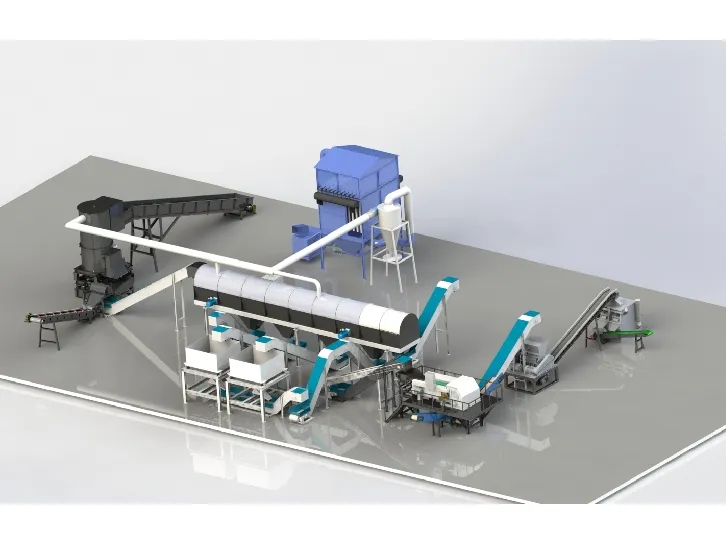

Proof of authoritative design capabilities is best embodied through case studies and user testimonials. Facilities utilizing well-designed ECS machines often report significant improvements in metal recovery efficiency and reduced operational costs. Documenting these success stories not only builds credibility but also provides potential clients with the assurance of proven performance.

In conclusion, creating an eddy current separator that meets modern industrial demands requires a profound integration of detailed design, real-life application experience, and cutting-edge technology. Emphasizing expertise and trustworthiness through rigorous testing, agile design processes, and user-centric innovation secures a competitive edge in the market. The ultimate goal remains to develop a product that not only meets industry standards but exceeds expectations, driving forward the sustainable practices of tomorrow.