In the competitive world of recycling and material processing, the eddy current non-ferrous separator has emerged as a game-changer for many industries. This innovative equipment is specifically designed to separate non-ferrous metals from waste streams, enhancing both efficiency and sustainability in recycling operations.

Imagine a machine that can swiftly and efficiently distinguish metals like aluminum and copper from mixed material streams with minimal human intervention. This is precisely what the eddy current non-ferrous separator accomplishes, using the science of electromagnetism. When non-ferrous metals pass through a powerful alternating magnetic field generated by the separator, eddy currents are induced within the metals. These currents then create their own magnetic fields that oppose the original magnetic field, propelling the metals away from the main material flow. The result is a streamlined separation process that is both effective and economical.

Experience shows that companies adopting eddy current non-ferrous separators report a dramatic increase in recovery rates of valuable metals. For instance, a prominent recycling facility noted a 30% rise in aluminum recovery without additional manual sorting, translating to substantial cost savings and increased profit margins. Operators consistently praise the user-friendly interface and the reduced need for maintenance due to its robust construction and design, offering reliability previously unachievable with traditional methods.

Expertise in the application and optimization of these separators is crucial. With various models available, tailored applications are necessary to address specific business needs. Factors such as belt speed, magnetic rotor speed, and particle size can significantly influence separation efficiency. For instance, slower belt speeds may enhance the recovery of smaller metal particles, while adjustments in rotor speed can optimize separation for larger items. Consulting with industry experts or manufacturers can provide invaluable insights into selecting and configuring the right equipment for your operation.

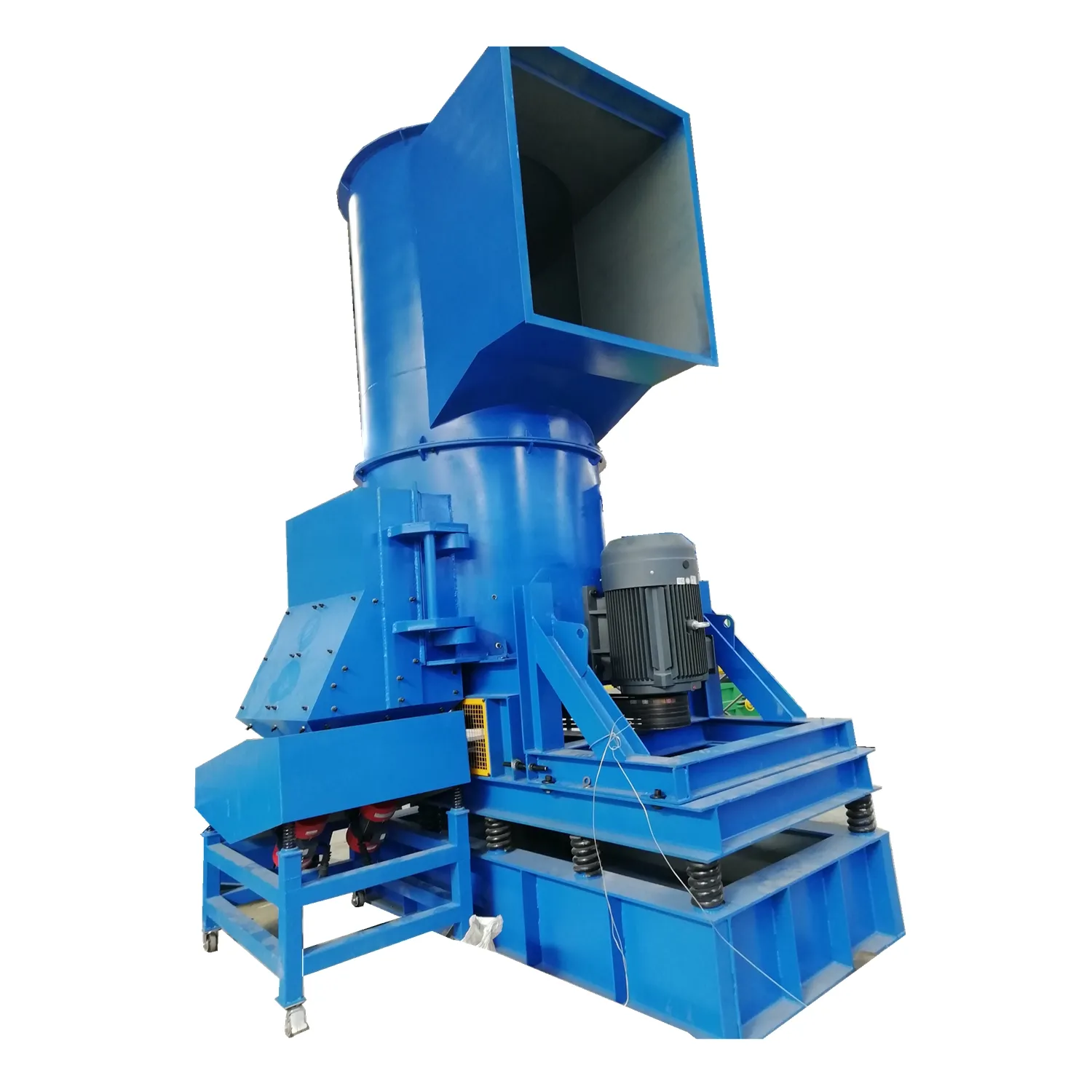

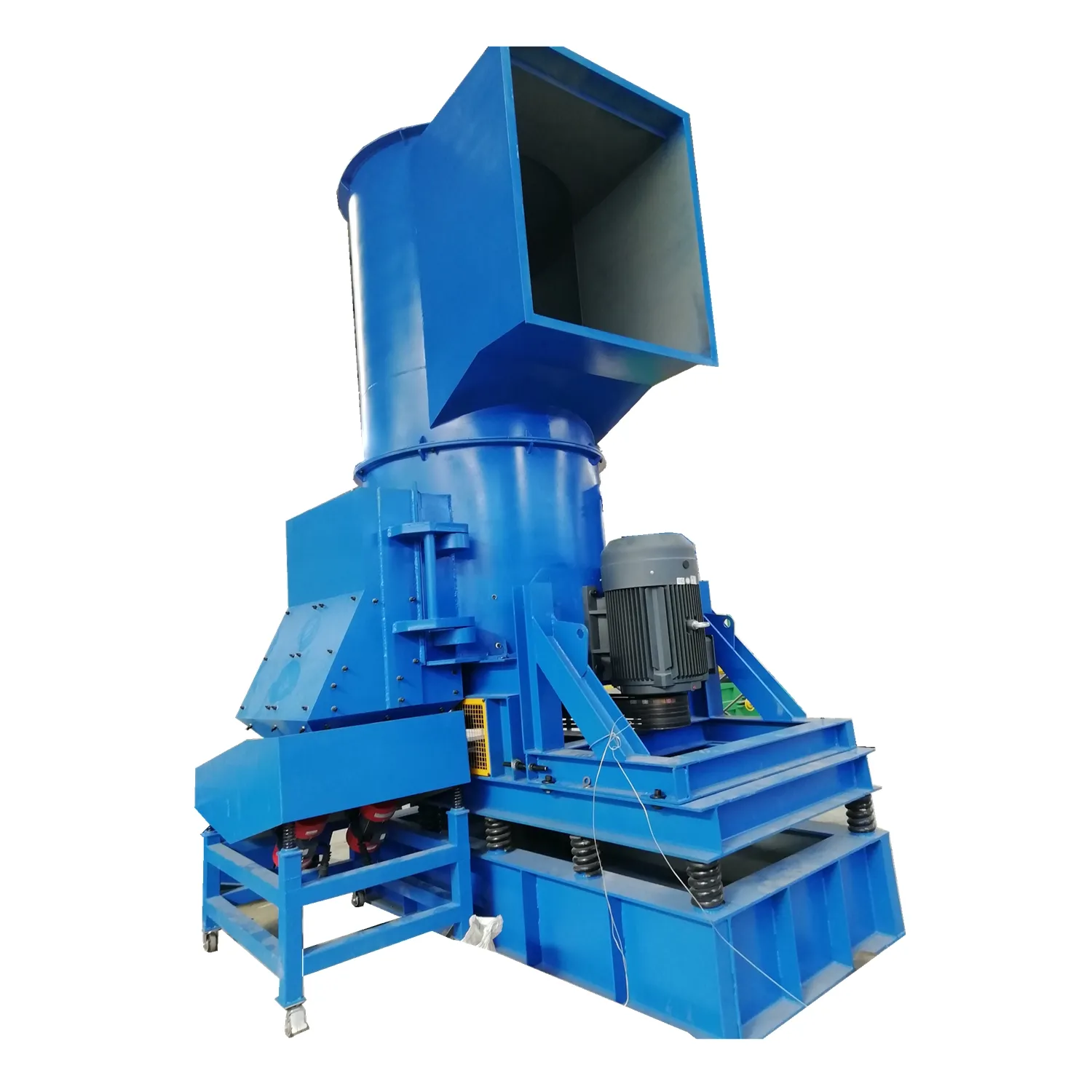

eddy current non ferrous separator

The authoritativeness of eddy current separators in the recycling industry is backed by extensive research and development. Manufacturers spend years perfecting the technology, ensuring compliance with international quality and safety standards. Publications in esteemed journals and conferences further attest to the device's capabilities and technological advancements. These separators not only contribute to a circular economy by maximizing metal recovery but also support industries in meeting stringent environmental regulations.

Trustworthiness is another pillar that reinforces the adoption of eddy current non-ferrous separators. Leading brands in the industry offer robust warranties and comprehensive after-sales support, ensuring equipment uptime and operational continuity. Case studies highlight success stories across various sectors, proving the separators' ability to handle different challenges and environments – from urban recycling centers to large industrial waste processing facilities.

Investing in an eddy current non-ferrous separator is not just a choice; it's a commitment to environmentally responsible and economically sound operations. By reducing manual labor and increasing metal recovery rates, businesses not only enhance their bottom line but also contribute to sustainable resource management. As industries continue to trend towards eco-friendliness and digitization, adopting advanced technologies like the eddy current separator positions companies at the forefront of innovation and ethical business practices.

In conclusion, the eddy current non-ferrous separator is a quintessential example of engineering excellence driving forward industry standards. Its continued development and application promise even greater advancements in recycling efficiency, making it an indispensable asset for any operation invested in metal recovery and environmental stewardship.