Eddy current aluminum separation has emerged as a transformative technology in the recycling industry, addressing the growing demand for efficient, sustainable, and cost-effective waste management solutions. This innovative process is paramount for industries focusing on non-ferrous metal recovery, particularly in the aluminum sector.

The use of eddy current separation technology is based on electromagnetic induction principles, leveraging the conductive properties of aluminum to separate it from other materials. As an established method, especially in recycling facilities worldwide, it showcases exceptional efficiency and environmental benefits by minimizing the need for manual sorting and reducing landfill waste.

One key advantage of the eddy current aluminum separation process is its ability to drastically improve throughput in recycling operations. Traditional methods of aluminum recovery often entail labor-intensive hand-picking or expensive smelting processes that consume considerable time and resources. In contrast, eddy current separators (ECS) are designed to handle large volumes of material with precision and speed, facilitating the reclamation of higher-quality aluminum at a faster rate.

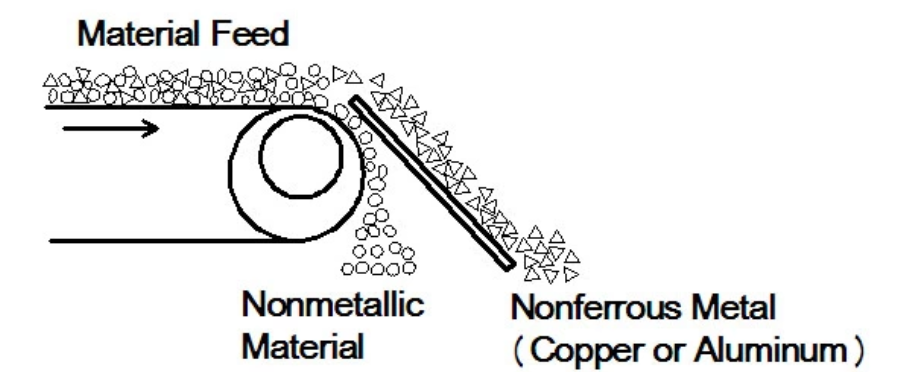

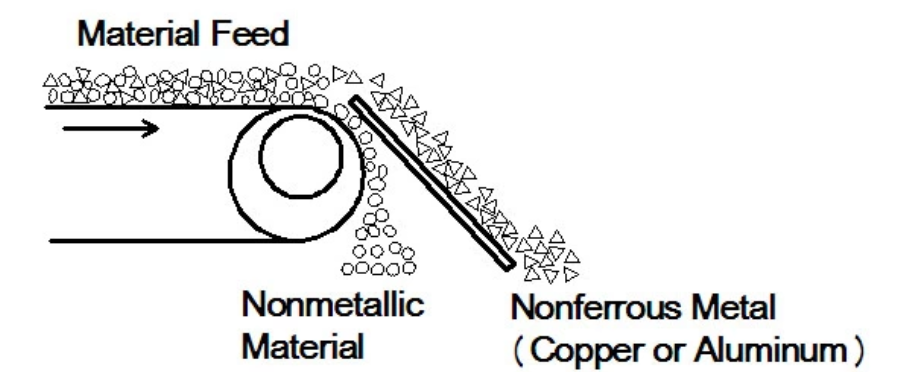

ECS systems, which come with variable designs to accommodate different operational needs, typically include rotating magnets accordingly arranged to create magnetic fields. When mixed materials pass over this rotor, non-ferrous metals such as aluminum experience repulsive forces, causing them to be propelled away from the rest of the waste stream. This efficiency not only contributes to lower operational costs but also optimizes the purity of the sorted aluminum output, which is crucial for industries that require a high level of material quality, such as automotive and aerospace manufacturing.

In terms of expertise, implementing eddy current separation technology demands a comprehensive understanding of material properties and the intricacies of electromagnetic principles. Engineers and designers continuously refine ECS systems, incorporating advancements in sensor technology and automation to enhance the precision of material separation. Cutting-edge developments have led to sophisticated adjustments in rotor speed and magnetic configurations, allowing for the customization of systems to target specific grades of aluminum, thereby maximizing recovery rates and improving profitability.

eddy current aluminum separation

Authoritativeness in this field is demonstrated by companies that leverage proprietary ECS technologies, often involving patented magnet systems and rotor designs unique to their products. Collaboration with universities and research institutions has also yielded significant improvements in equipment design and operational efficiency. Strong relations with regulatory bodies ensure compliance with environmental standards, allowing businesses to maintain a competitive edge.

Trustworthiness is a crucial factor for companies seeking to invest in eddy current aluminum separation technologies. Proven results backed by data on separation efficiency and throughput rates help build confidence in the systems. Testimonials from satisfied clients who have achieved substantial returns on investment through improved recycling capabilities add to this trust. Furthermore, commitment to service and support, demonstrated by offering training, maintenance, and real-time troubleshooting, ensures that clients remain confident in the long-term reliability of their ECS systems.

Product-level insights indicate that the selection of an eddy current separator should be aligned with specific operational needs. Factors such as the size of the facility, the volume of material processed, and the types of waste streams encountered guide the decision-making process. Modular ECS systems provide flexibility, allowing for integration into existing lines and scalability as production demands increase.

In summary, eddy current aluminum separation is revolutionizing how industries approach aluminum recovery. With a foundation rooted in advanced electromagnetic technology, expertise in system design, authoritative research, and a commitment to sustainable industrial practices, ECS stands as an indispensable tool for modern recycling efforts. Its capacity to bolster aluminum recovery with unmatched efficiency positions it as a critical component for industries dedicated to maximizing resource utilization and minimizing environmental impact.